Bilateral efficient vortex tube heater

A vortex tube, double-sided technology, applied in the direction of pipeline heating/cooling, pipes/pipe joints/fittings, mechanical equipment, etc., can solve the problems of inconvenient heat exchange efficiency, low heat exchange efficiency, and no adjustment device, etc. To achieve the effect of ensuring normal operation and improving heating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0015] The double-sided high-efficiency vortex tube heater of the present invention, its preferred embodiment is:

[0016] It includes a metal outer cylinder, a vortex tube is arranged inside the metal outer cylinder, a vortex chamber is connected to one end of the vortex tube, the other end of the vortex tube is opened and a regulating valve is provided, and a heat sink is installed outside the vortex tube. An exchanger, an external heating layer is provided between the heat exchanger and the metal outer cylinder, and a local heating area of the vortex chamber is provided between the vortex chamber and the metal outer cylinder;

[0017] The side wall of the metal outer cylinder is provided with a pilot gas inlet and a pilot gas outlet at a position corresponding to the vortex tube, and the pilot gas inlet and pilot gas outlet are respectively connected to the heat exchanger;

[0018] The side wall of the metal outer cylinder is provided with one or more high-pressure natura...

specific Embodiment

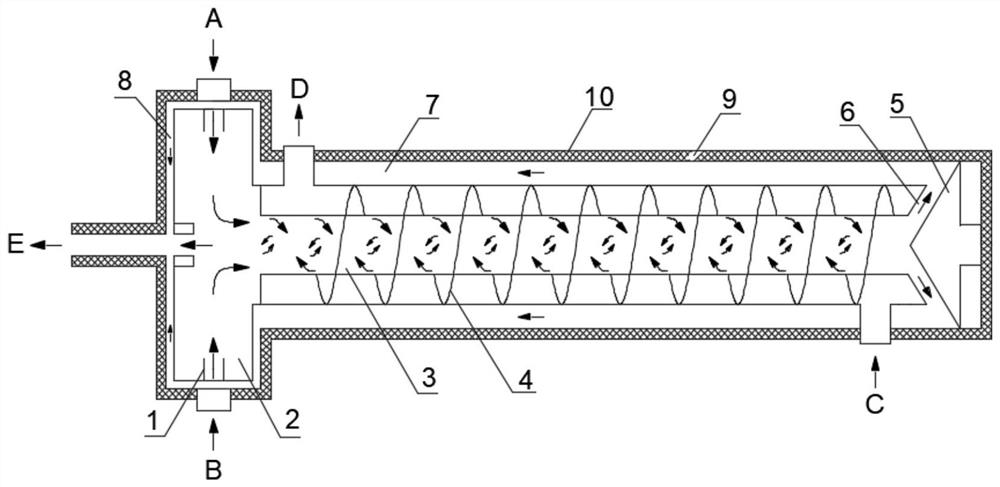

[0027] Such as figure 1 As shown, the double-sided high-efficiency vortex tube heater provided by the present invention includes: 1 - decompression nozzle; 2 - vortex chamber; 3 - vortex tube; 4 - heat exchanger; 5 - regulating valve; 6 - hot gas channel; 7—outer heating layer; 8—local heating area of vortex chamber; 9—insulation layer; 10—metal outer cylinder (including high-pressure natural gas inlet, low-pressure natural gas outlet and pilot gas inlet and outlet); A, B—high-pressure natural gas inlet; C—pilot Gas inlet; D—pilot gas outlet; E—low pressure natural gas outlet.

[0028] The heating function of the present invention:

[0029] High-pressure natural gas enters from high-pressure natural gas inlets A and B, and reaches the vortex tube 3 through the decompression nozzle 1 and the vortex chamber 2. The gas in the vortex tube 3 is divided into the outer hot swirl flow and the inner cold swirl flow. The natural gas is discharged from the outlet E, and the hot gas i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com