Processing method of TPMS structure with continuous gradient wall thickness based on 3D printing

A technology of 3D printing and processing methods, applied in 3D modeling, instruments, design optimization/simulation, etc., to achieve wide selection and good control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

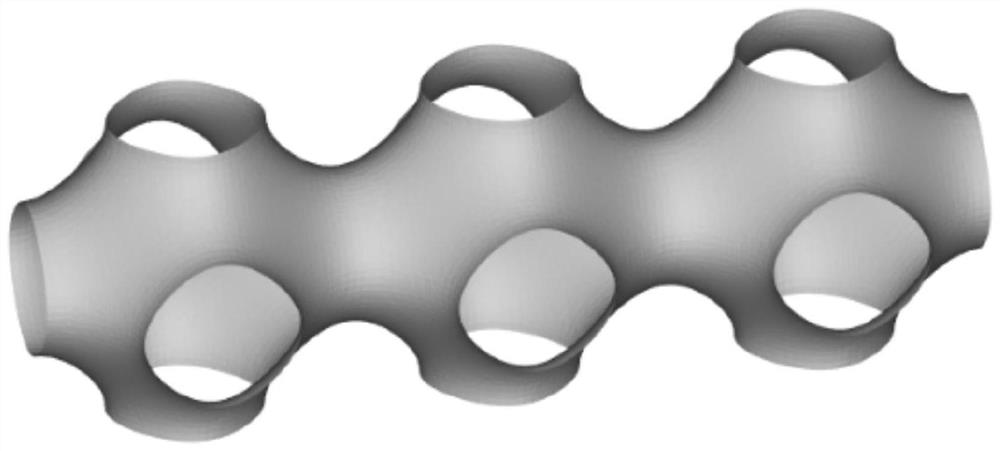

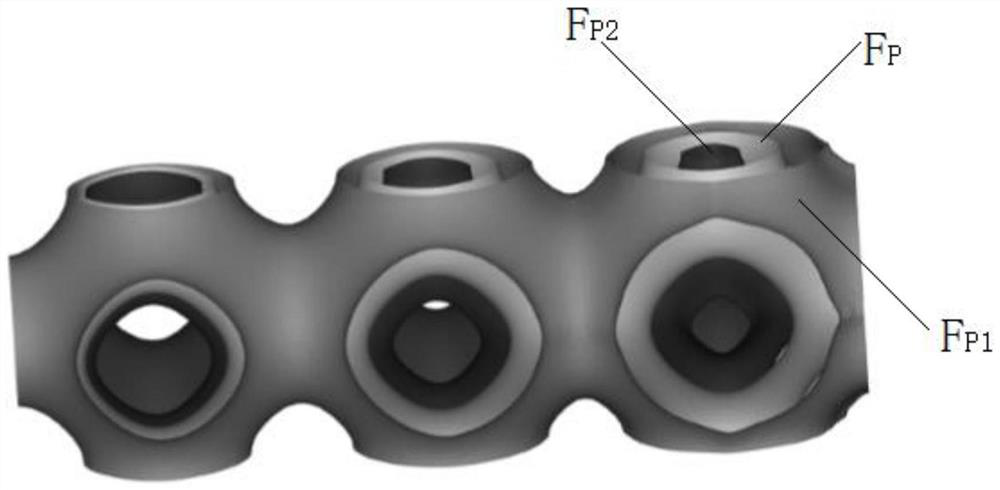

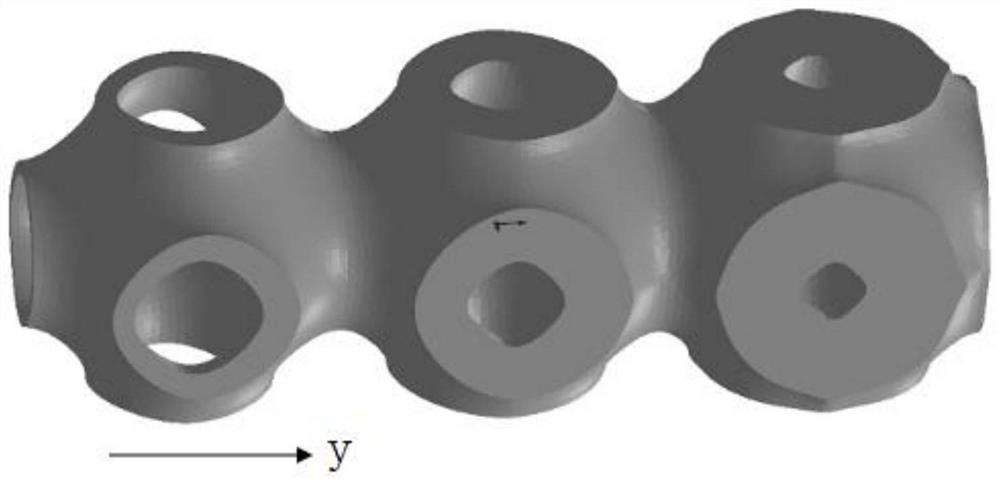

[0031] Step 1, this embodiment takes the Schwarz P minimal surface as an example, such as figure 1 As shown, the initial surface equation is:

[0032] f P (x, y, z) = cos x + cos y + cos z = 0;

[0033] Then take the structure in a 2π×6π×2π cube, namely x∈(-π,π), y∈(-3π,3π), z∈(-π,π), and choose the thickening function T P (x, y, z)=0.1y+1.2, that is, on the basis of the initial curved surface, the amount of thickening will gradually increase along the y direction, and the whole is a curved surface structure with continuous gradient wall thickness and minimal thickness.

[0034] The normal vector is:

[0035]

[0036] The two thickened corresponding point set relational expressions are:

[0037]

[0038]

[0039] The two point sets obtained above are respectively substituted into the Schwarz P minimal surface equation, and the two surface equations of gradient wall thickness can be obtained, respectively:

[0040]

[0041] Step 2, using the point set obtaine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com