Slotless brushless grooved drum permanent magnet synchronous motor comprising special controller and rotary transformer

A permanent magnet synchronous motor, resolver technology, applied in synchronous motors with static armatures and rotating magnets, connected to control/drive circuits, electrical components, etc., can solve the problem of weak overload capacity, large eddy current loss, tooth Heat generation and other problems, to achieve the effect of increasing the voltage level, small eddy current loss, and increasing the current level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

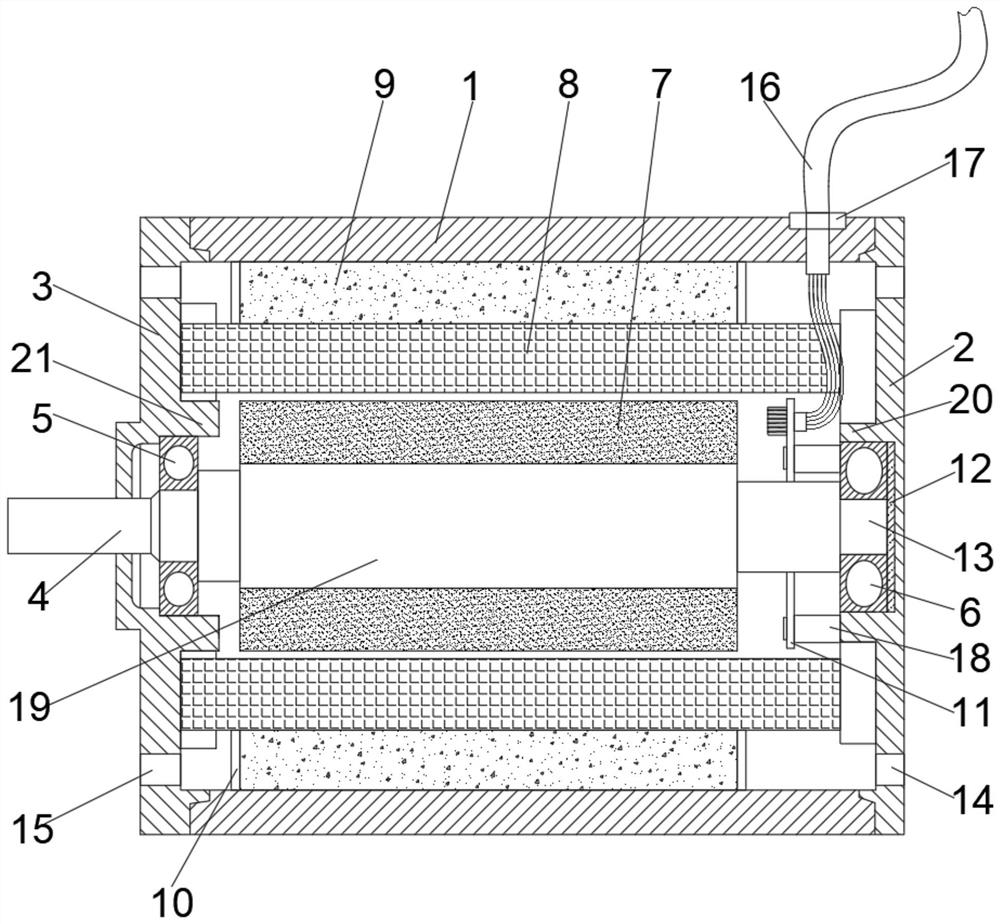

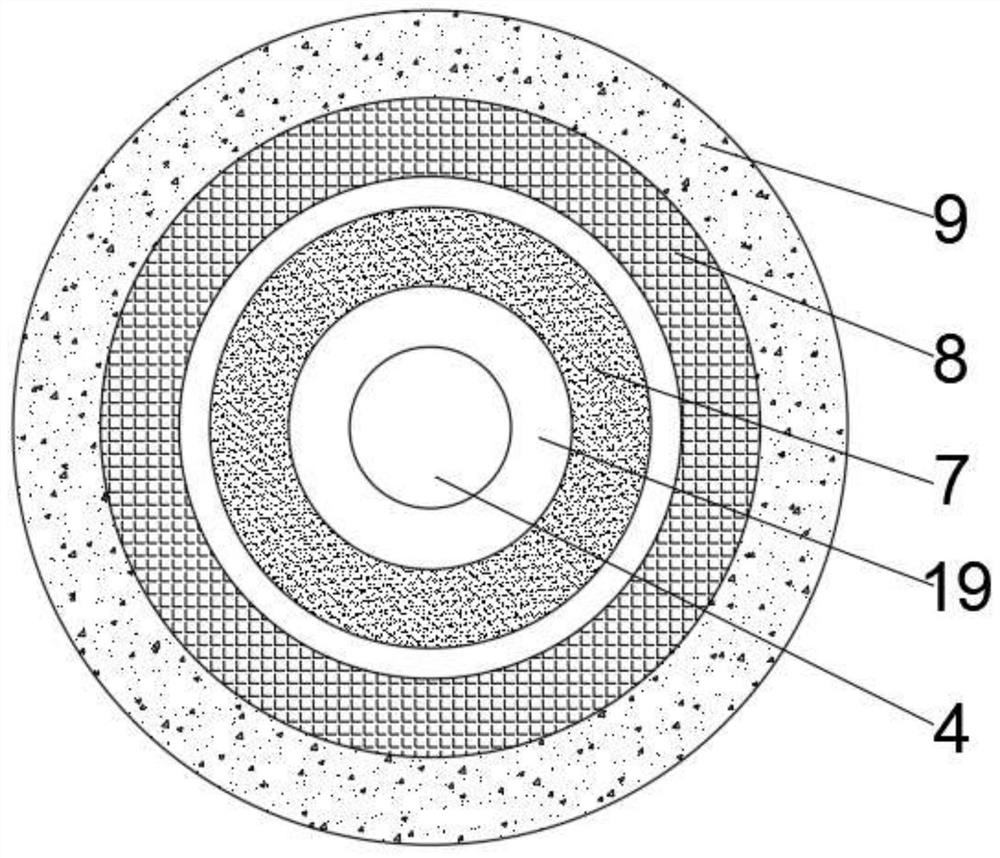

[0023] Such as Figure 1-2 As shown, the embodiment of the present invention provides a slotless brushless drum permanent magnet synchronous motor including a dedicated controller and a resolver, including a motor housing 1, a motor rear cover 2, a motor front cover 3, and a motor front cover 3 and the motor rear cover 2 are respectively fixedly connected to the front and rear ends of the motor housing 1, the motor rear cover 2 is fixedly provided with a rear boss 20 near the center of the front end side wall, and the motor front cover 3 is fixedly provided with a rear boss near the center of the rear end side wall. Front boss 21, the inner end of front boss 21 is provided with front bearing 5, the inner end of rear boss 20 is provided with rear bearing 6, the inner end of front bearing 5 is provided with main shaft 4 for rotation, and the rear end of main shaft 4 is fixedly arranged There is a high-precision rotary transformer 13, and the high-precision rotary transformer 13 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com