Method and system for driving a stepper motor

A technology of stepping motors and driving methods, applied in control systems, motor generator control, electrical components, etc., can solve problems such as difficult to start and stop, accompanied by howling, and large operating noise, reaching important markets Value, noise reduction, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The technical solution of the present invention will be described in detail below with reference to the drawings and embodiments.

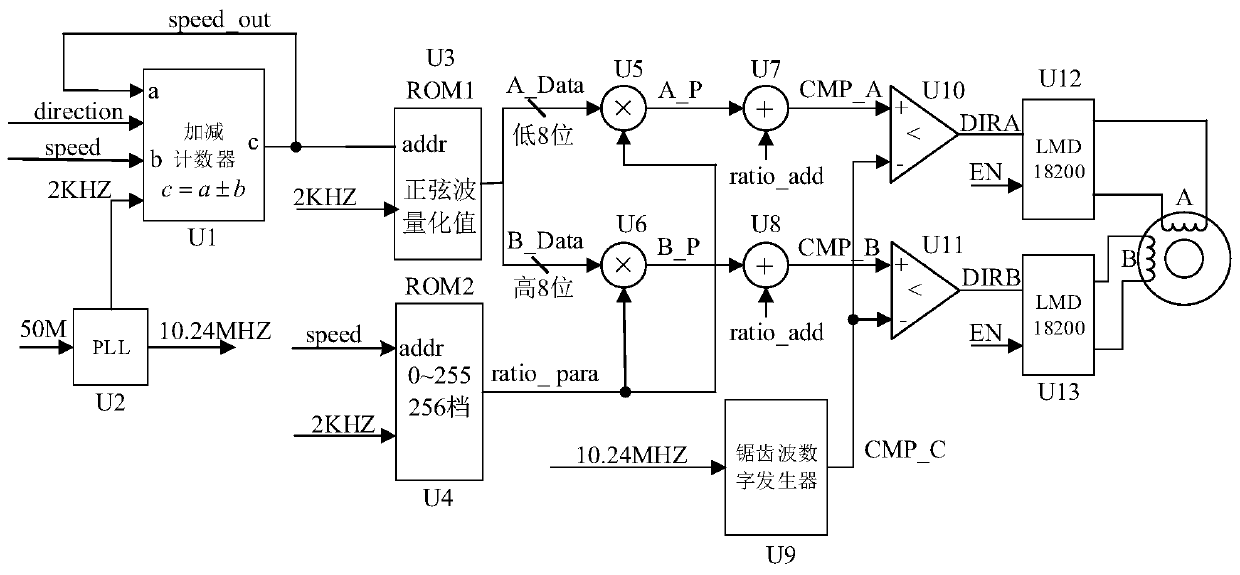

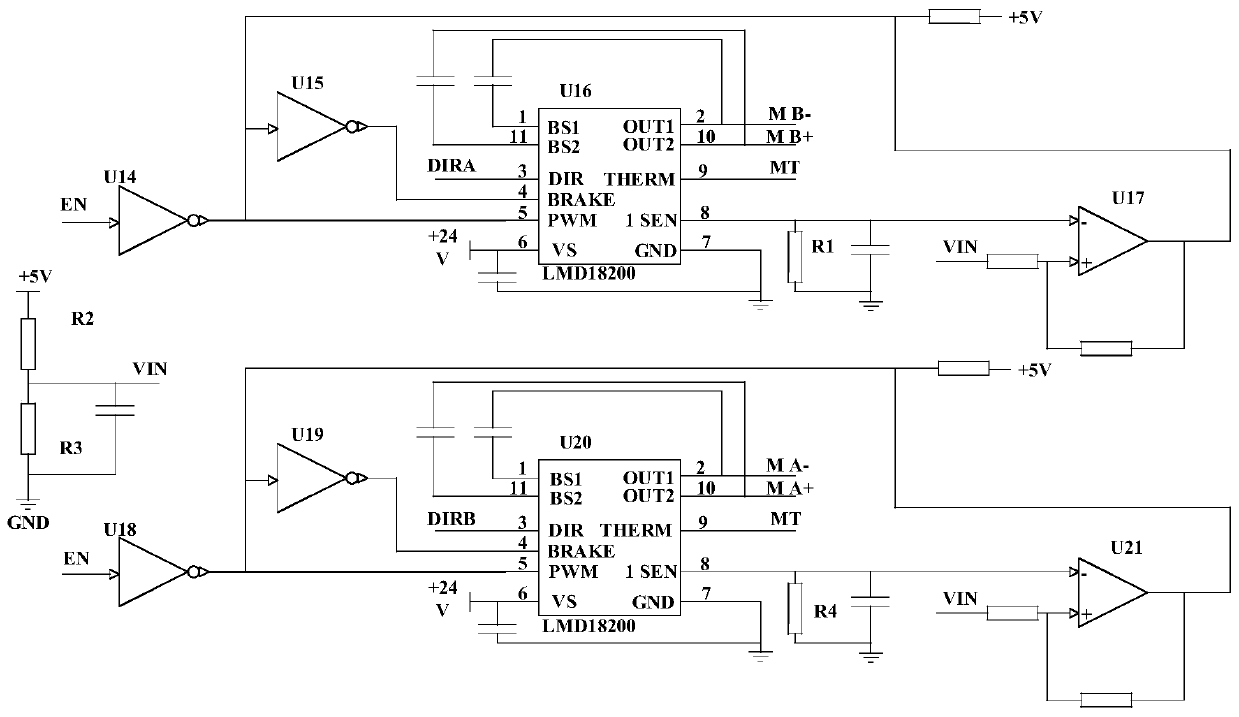

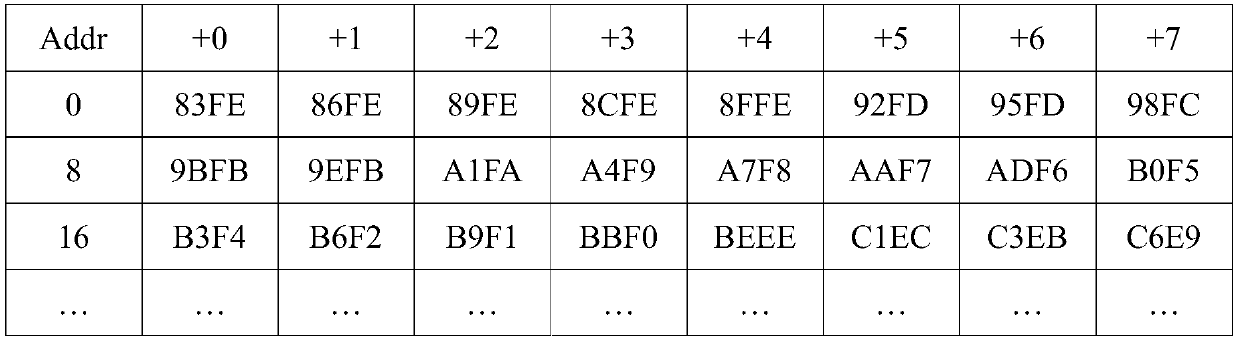

[0041] The invention provides a stepping motor driving method and system in combination with FPGA technology. Such as figure 1 As shown, the embodiment of the present invention proposes to set up and down counter U1, phase-locked loop U2, first read-only memory U3 (marked as ROM1), second read-only memory U4 (marked as ROM2), multipliers U5 and U6, adder Devices U7 and U8, sawtooth wave digital generator U9, comparators U10 and U11, and motor drive circuits U12 and U13. Such as figure 1The up-down counter U1 is connected to the first read-only memory U3, and the phase-locked loop U2 is connected to the up-down counter U1, the first read-only memory U3, the second read-only memory U4 and the sawtooth wave digital generator U9, so The first read-only memory U3 is connected to multipliers U5 and U6, the second read-only memory U4 is connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com