Bio-organic fertilizer raw material mixing device

A bio-organic fertilizer and mixing device technology, applied in the field of agriculture, can solve the problems of poor mixing effect and achieve the effect of improving the mixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

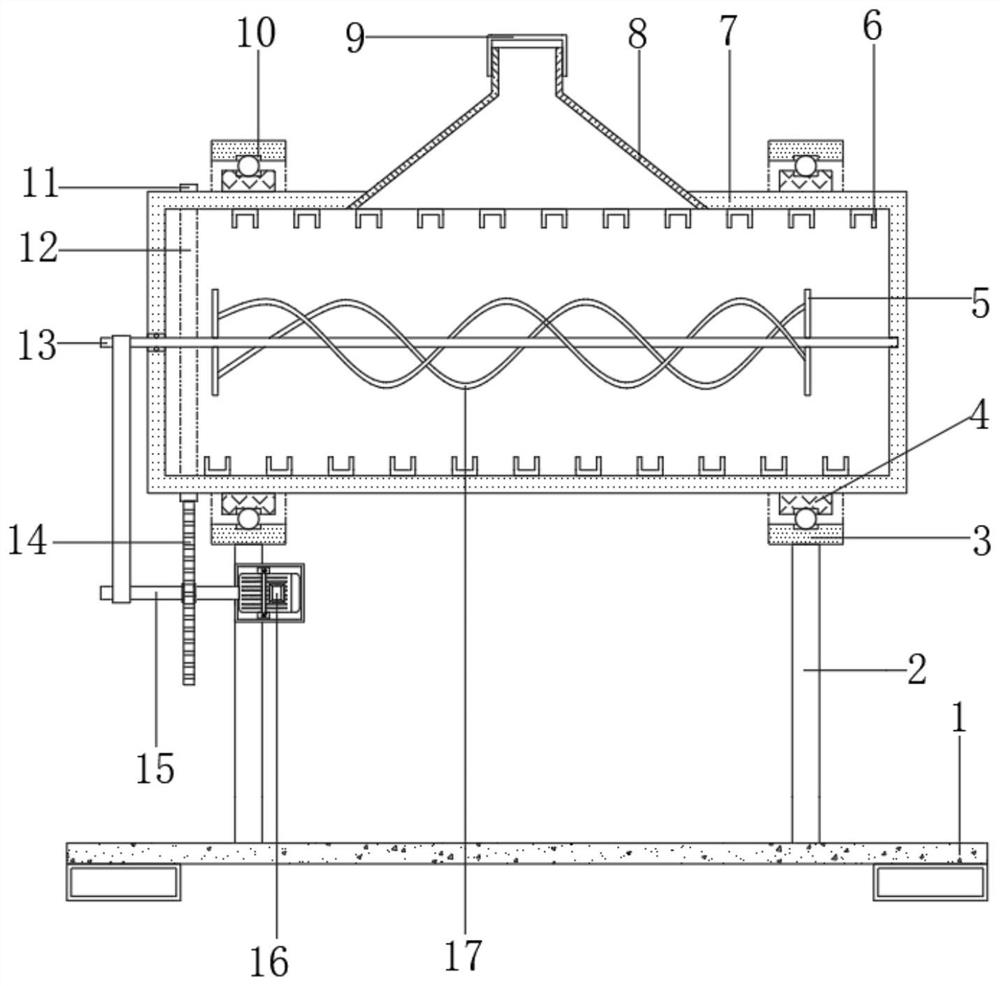

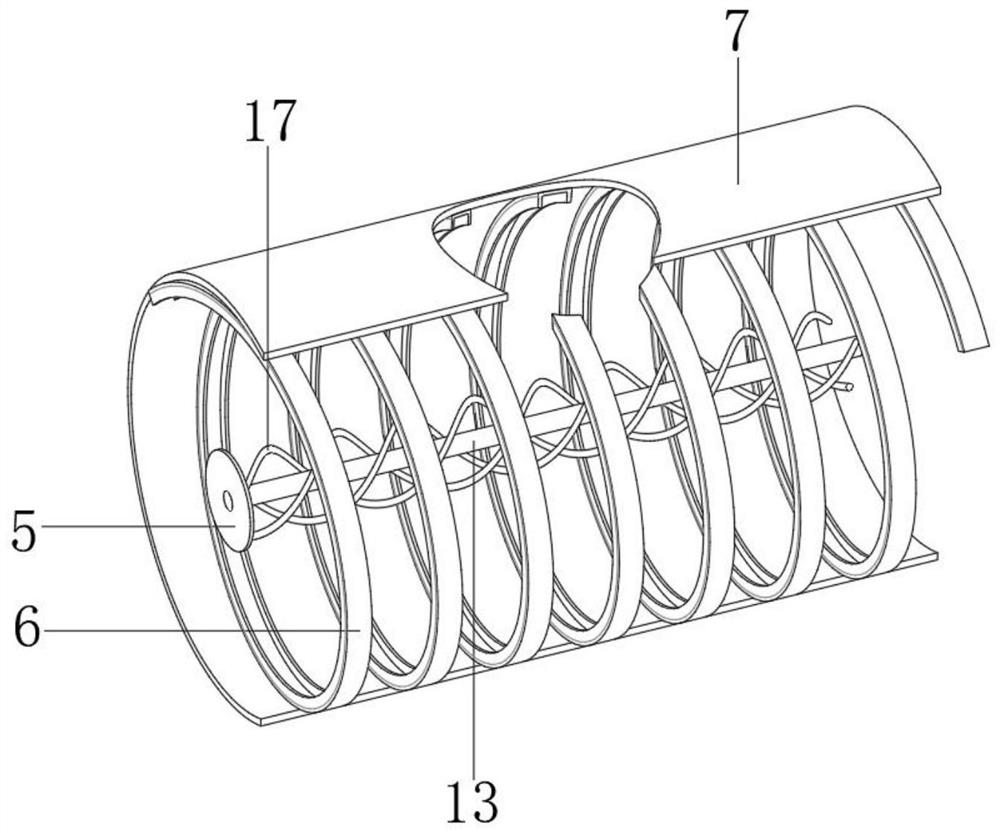

[0026] refer to Figure 1-2 , a bio-organic fertilizer raw material mixing device, comprising a base 1 with legs welded at the four corners of the outer wall of the bottom, side braces 2 are welded vertically at both ends of the top outer wall of the base 1, and fixed rings are welded at the top of the side braces 2 plate 3, and the inside of the fixed ring plate 3 is provided with the same mixing tank 7, the inside of the mixing tank 7 is connected to the rotating rod 13 through the bearing rotation, and the two ends of the rotating rod 13 are welded with the end ring plate 5, and the two ends The opposite side of the ring plate 5 is welded with annularly distributed screw rods 17, the interior of the mixing tank 7 is set as a cylindrical mixing chamber 12, and the outer wall of one end of the mixing tank 7 is keyed with a toothed ring 11, one of the side support plates 2. A rotating motor 16 is fixed by bolts, and a spiral inner plate 6 is welded on the peripheral outer wall...

Embodiment 2

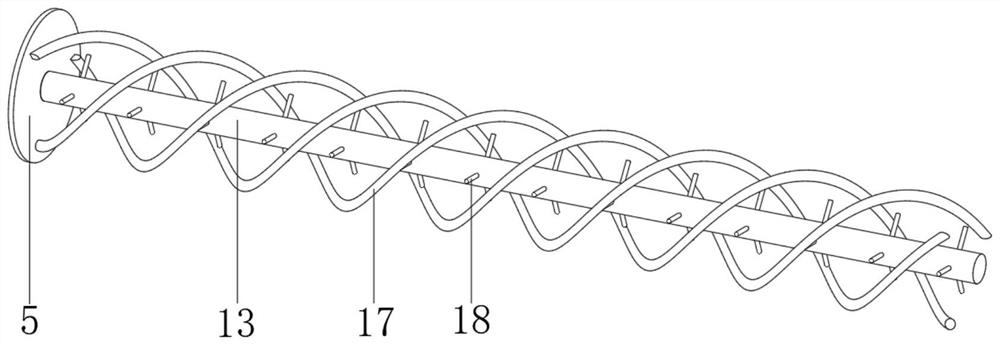

[0034] refer to image 3 , a bio-organic fertilizer raw material mixing device. Compared with Embodiment 1, this embodiment further includes that the outer peripheral wall of the rotating rod 13 is welded with equidistantly distributed struts 18 .

[0035] When the present invention is in use: Utilize the support rods 18 equidistantly distributed on the outer wall of the rotating rod 13, during the rotation process of the rotating rod 13, the supporting rods 18 can rotate accordingly, which plays a certain auxiliary mixing effect on the raw materials, and further improves the mixing efficiency of the raw materials. mixed effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com