Feed mixing and drying device for animal husbandry

A drying device and animal husbandry technology, which is applied to feed, mixers, mixers with rotating containers, etc., can solve the problems of a single action mode of a stirring mechanism, a single action range, a poor mixing effect, and a slow release of water vapor. Improve drying effect, improve mixing effect, increase heat exchange area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

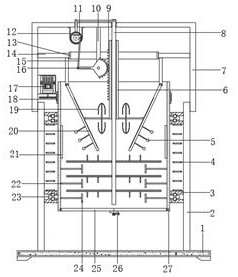

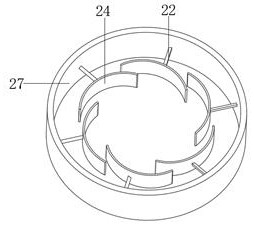

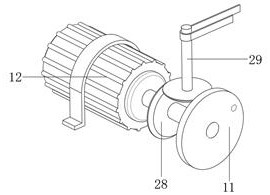

[0030] refer to Figure 1-4 , a feed mixing and drying device for animal husbandry, comprising a base 1 with feet welded at the four corners of the bottom outer wall, fixed arm frames 2 are vertically welded to both ends of the top outer wall of the base 1, and the opposite side of the fixed arm frame 2 is provided with The tank body 27, and the outer walls of both ends of the tank body 27 are welded with convex ring plates 23, the side of the fixed arm frame 2 near the convex ring plate 23 is welded with a support ring plate 3, and the end of the fixed arm frame 2 near the top is welded There is a top frame 7, and the middle end of the top frame 7 is welded with a connecting arm column 14 horizontally, and the opposite side of the connecting arm column 14 is welded with the same reinforcing ring 13, and the middle end of the top frame 7 is connected with a rotating column through a bearing rotation 8, and the outer wall of one end of the rotating column 8 is slidingly connect...

Embodiment 2

[0041] refer to Figure 5 , a feed mixing and drying device for animal husbandry. Compared with Embodiment 1, this embodiment also includes that one end of the lug plate 21 is welded with an arc dial 30 .

[0042] When the present invention is in use: use the arranged arc plate 30 to cooperate with the convex plate 21 to further increase the heat exchange area of the feed, and during the rotation of the tank body 27, gaps appear intermittently in the heating place of the feed, which is conducive to the release of water vapor , in order to achieve the purpose of improving the drying effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com