A mixing agitator for the production of energy-saving and environment-friendly building material coatings

An energy-saving, environmentally friendly, mixing and stirring technology, which is applied to mixers, mixer accessories, mixers with rotating stirring devices, etc., can solve problems such as inconvenient cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

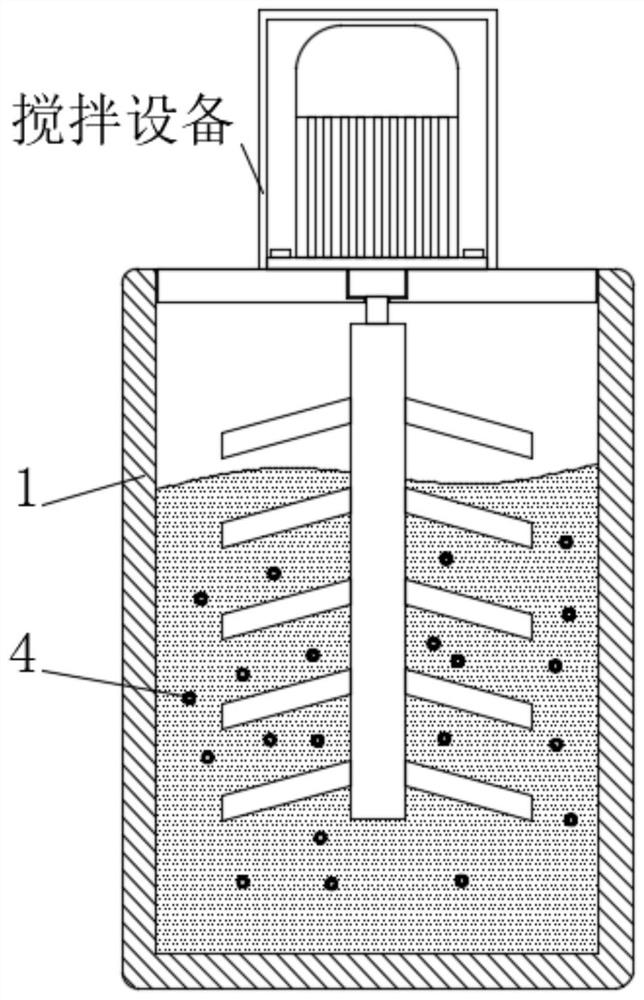

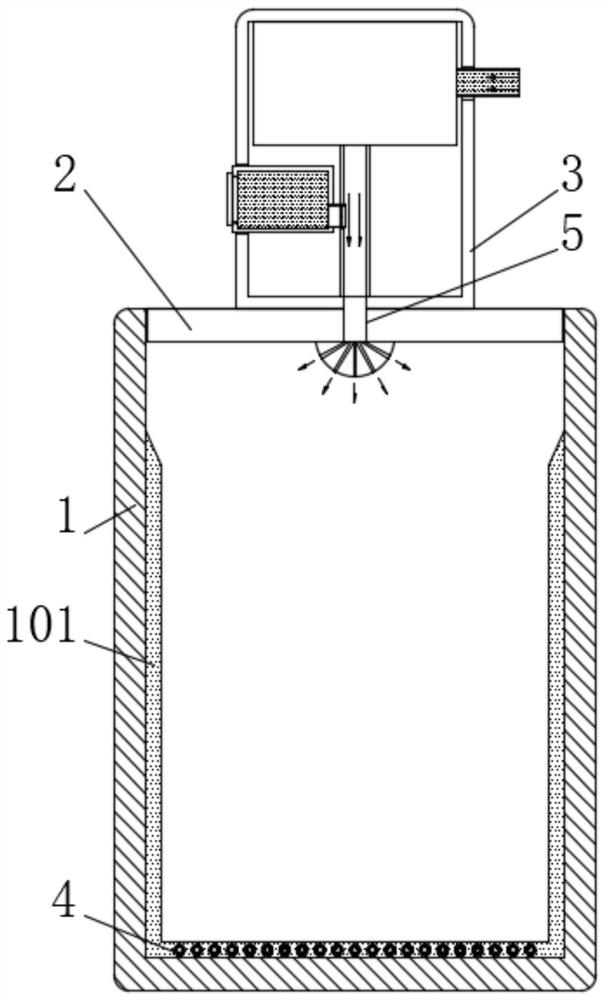

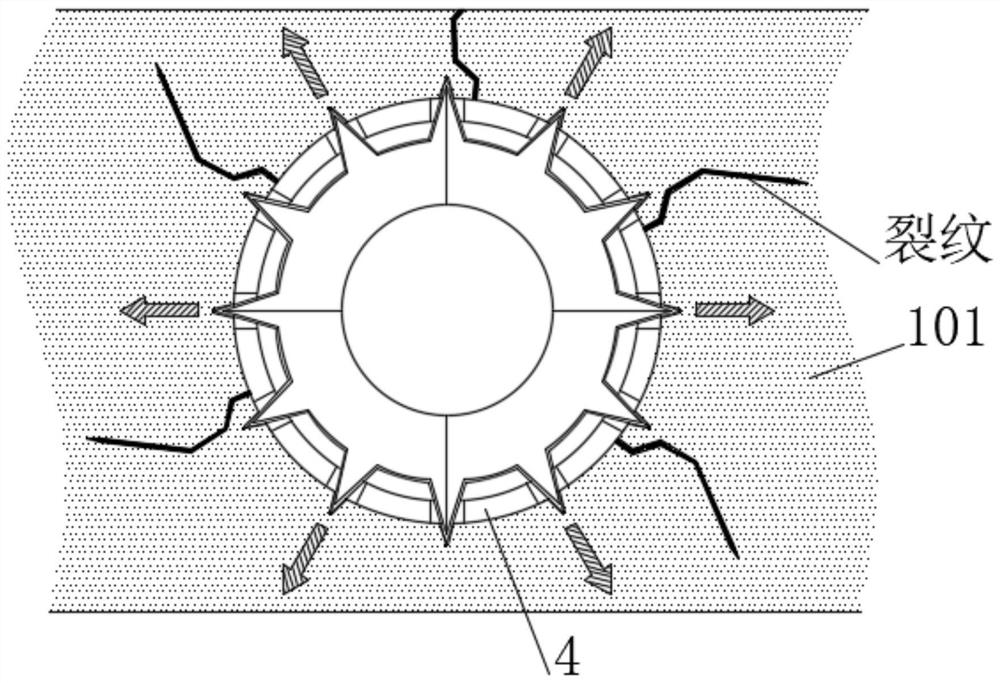

[0045] see Figure 1-8 , an energy-saving and environment-friendly mixing mixer for the production of building material coatings, including a mixing paint mixing box 1, a heating device is installed inside the mixing paint mixing box 1, and the mixing paint mixing box 1 can be heated by the heating device, so that the mixed paint mixing box 1. The paint coating 101 on the inner wall dries up, thereby accelerating its cracking and falling off. The upper end of the mixed paint mixing box 1 is threadedly connected with a connecting sealing plate 2, and the upper end of the mixing paint mixing box 1 is installed with a stirring device during the stirring process. The stirring device includes The motor and the stirring paddle are fixedly connected to the upper end of the sealing plate 2 with the injection box 3, and the inner wall of the mixing paint mixing box 1 is provided with a paint coating 101, and the paint coating 101 is provided with a plurality of evenly distributed built-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com