Slitting equipment for thin plate

A sheet and equipment technology, applied in the field of thin sheet cutting equipment, can solve problems such as low processing efficiency, and achieve the effect of convenient maintenance and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

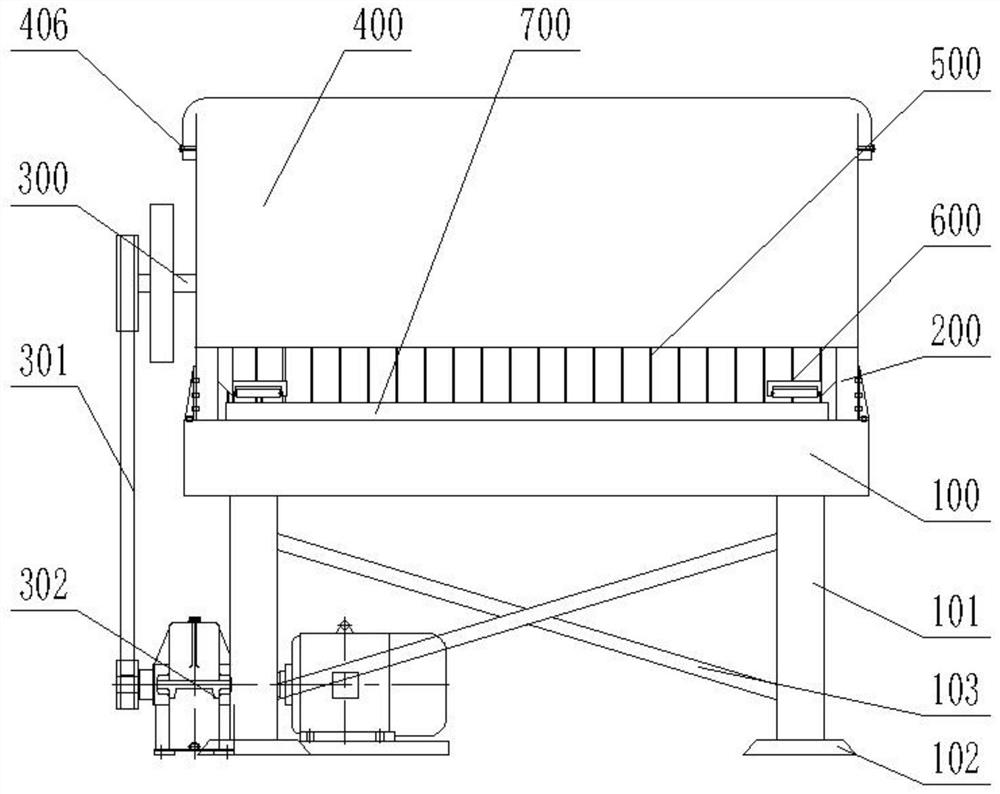

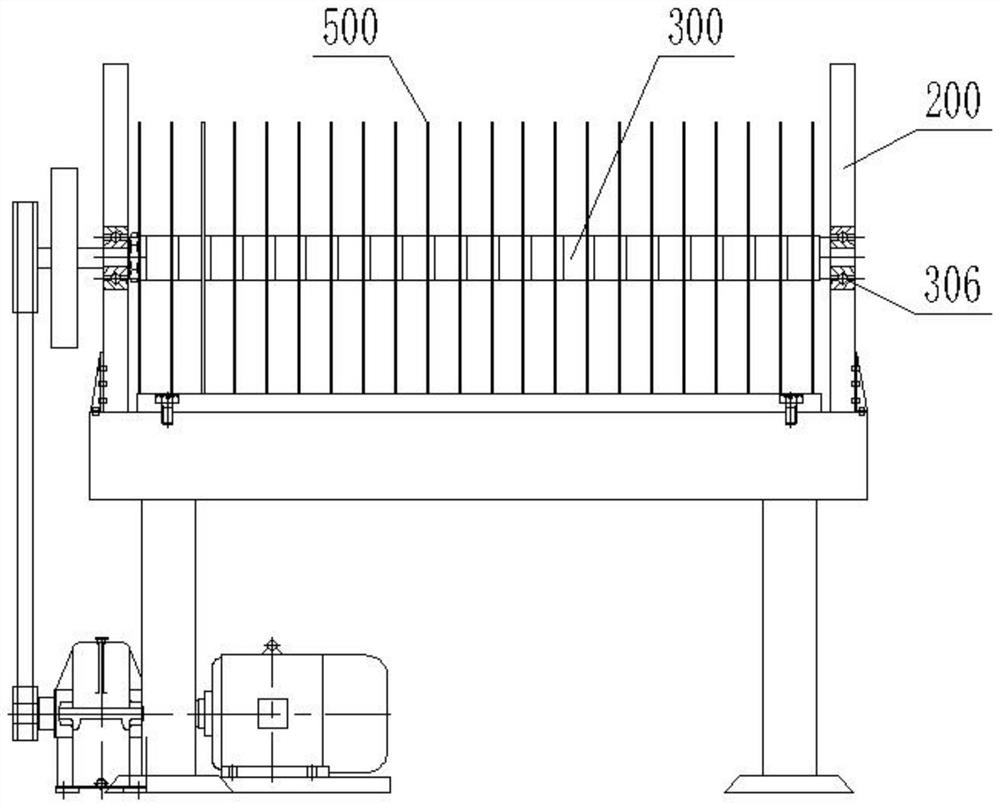

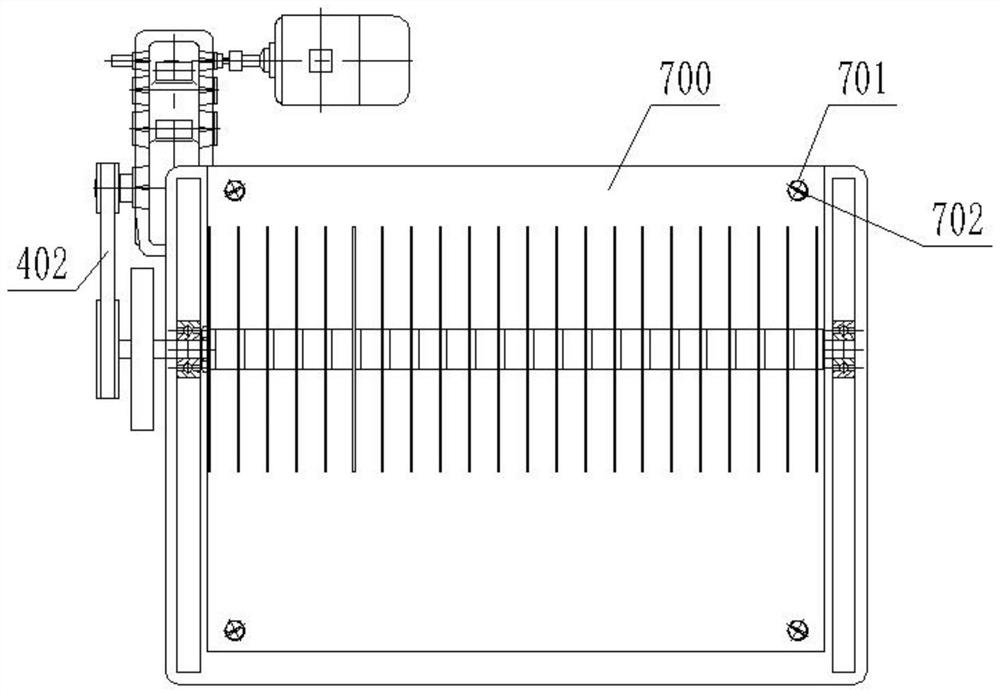

[0039] see Figure 1-10 , a cutting device for thin plates, including a base 100, a table 700, a shell 400 and a pressing device 600,

[0040] The four corners of the base 100 are provided with supporting legs 101, wherein the supporting legs 101 are fixedly connected with lacing bars 103 arranged obliquely to improve the strength of the structure, and the bottom of the supporting legs 101 is fixedly provided with supporting feet 102, and the supporting feet 102 are truncated cone,

[0041] The left and right sides of the top of the base 100 are symmetrically provided with support plates 200, and a cutting shaft 300 is arranged between the support plates 200. Both ends of the cutting shaft 300 are connected to the support plate 200 through first bearings 306 for rotation, wherein the cutting shaft The left end of 300 passes support plate 200,

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com