Positioning tool with good stabilizing effect for machining

A technology of machining and positioning tooling, applied in workpiece clamping devices, manufacturing tools, etc., can solve the problems of single fixing method and general workpiece fixing stability, and achieve the effect of improving anti-skid performance, improving stability and increasing contact area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

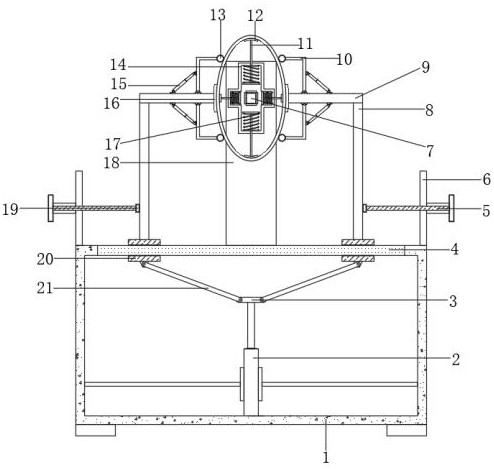

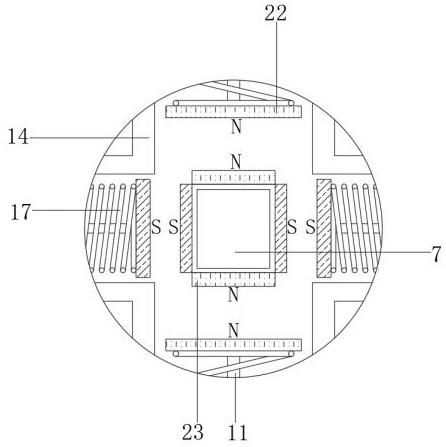

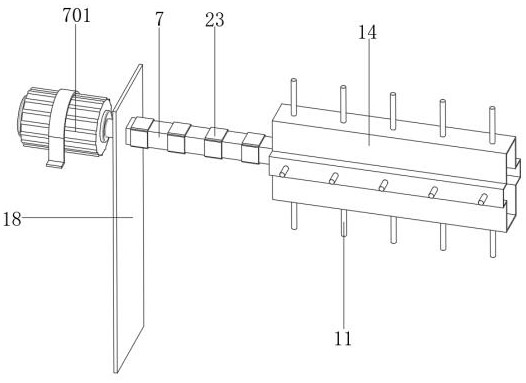

[0030] refer to Figure 1-4 , a positioning tool with high stabilizing effect for mechanical processing, comprising a box seat 1 with legs welded at the four corners of the outer wall of the bottom, bar-shaped chute 4 is opened on both sides of the top outer wall of the box seat 1, and the bar-shaped chute 4 Both ends are slidably connected with frame-shaped sliders 20, and the top outer walls of the two frame-shaped sliders 20 are vertically welded with a connecting plate 8, and the top of the connecting plate 8 is fixedly equipped with a clamping mechanism, and the top of the box seat 1 One side of the outer wall is vertically welded with a side support plate 18, and the side support plate 18 is equipped with an internal support mechanism. A rotating column is connected through bearing rotation, and one end of the rotating column is welded with a square inner column 7, and the four corners of the inner wall of the cross inner cylinder 14 are slidably connected with movable s...

Embodiment 2

[0040] refer to Figure 5 , a positioning tool with high stabilizing effect for mechanical processing. Compared with Embodiment 1, this embodiment also includes butterfly-shaped lugs 26 fixedly installed on both sides of the frame-shaped slider 20 .

[0041] In the present invention, the inner walls of both sides of the bar-shaped chute 4 are provided with oblique corner grooves 25 matching the butterfly-shaped lugs 26 .

[0042] When the present invention is used: the butterfly-shaped lugs 26 are arranged on both sides of the frame-shaped slider 20, and the oblique angle groove 25 can be used to increase the contact area between the frame-shaped slider 20 and the box seat 1, and the movement of the frame-shaped slider 20 can be improved. stability, in order to achieve the purpose of ensuring the smooth progress of the clamping operation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com