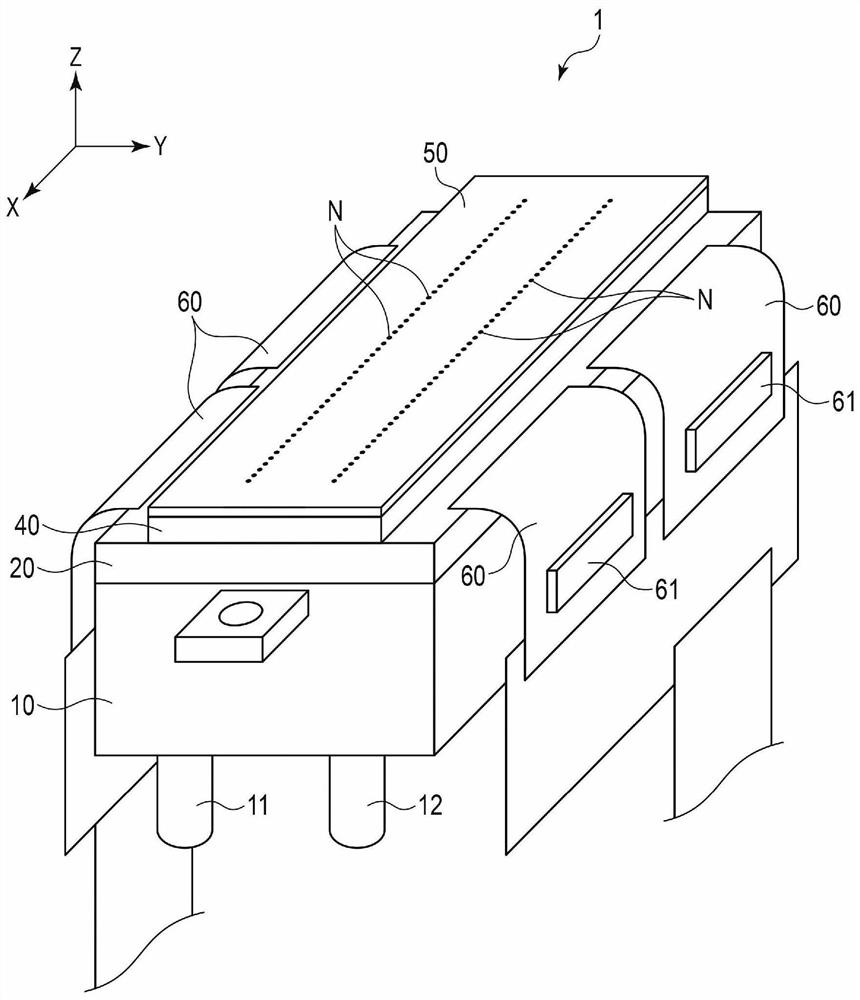

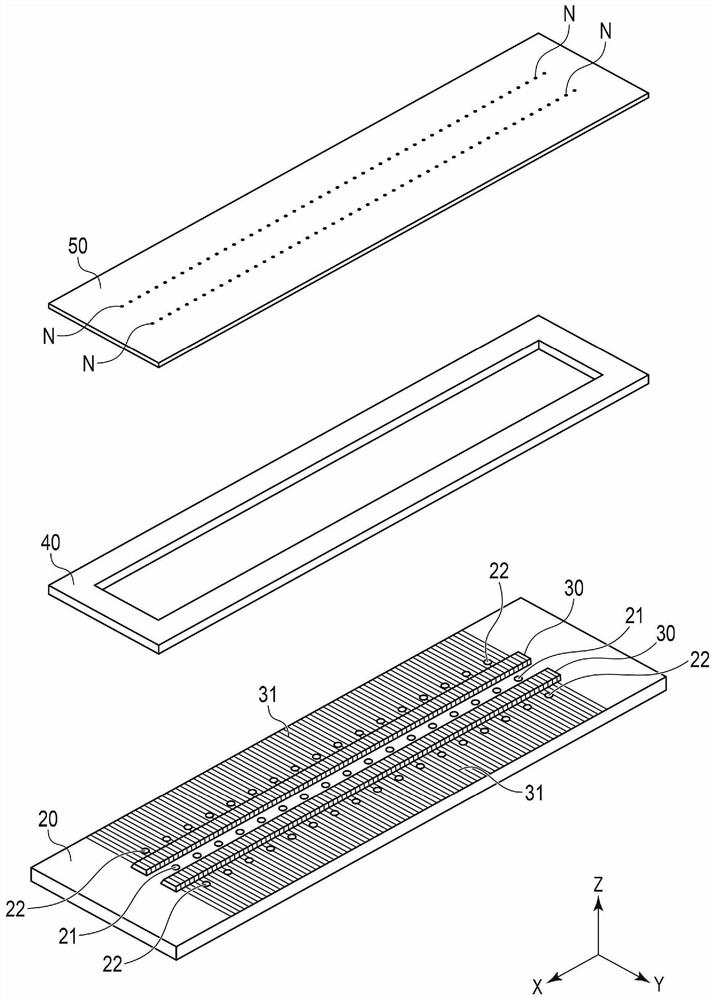

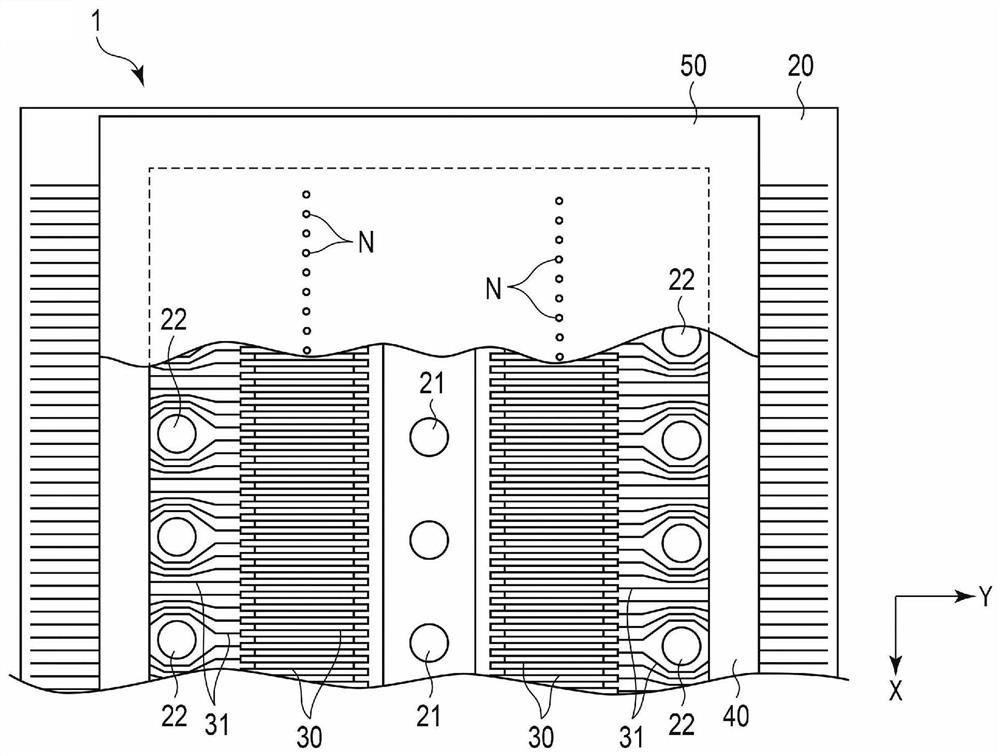

Ink jet head and ink jet printer

An inkjet head, ink technology, used in printing and other directions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

reference example 1

[0098] First, a fluorine-containing resin-containing liquid obtained by dissolving a fluorine-containing resin in a fluorine-containing solvent was prepared. As the fluorine-containing resin, Cytop (registered trademark) A type manufactured by Asahi Glass Co., Ltd. was used.

[0099] Next, the fluorine-containing resin-containing liquid was applied to the surface of the nozzle plate base material by a spin coating method, and the coating film was subjected to heat treatment. The heat treatment temperature is 180° C., and the heat treatment time is 30 minutes. A polyimide film was used as the base material of the nozzle plate.

[0100] In this way, a nozzle plate comprising a lyophobic film comprising a compound having a ring structure is obtained. The film thickness of the lyophobic film was 200 nm.

Embodiment 1

[0102] Using the nozzle plate obtained by the method of Reference Example 1 above, the inkjet head 1 was manufactured by the above method. In the reheating treatment, the heating temperature was 205° C., and the heating time was 2 hours. The cooling treatment was performed at a rate of 1.5°C / min until reaching 40°C.

[0103] In this way, an inkjet head including a liquid-repellent film comprising a compound in which a part of the ring structure is ring-opened is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Film thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com