A protective control device for a conveyor in a coal mine

A protection control, conveyor technology, applied in the direction of conveyor control devices, conveyor objects, cleaning devices, etc., can solve the problems of inconvenient use, increased conveyor belt load, safety accidents, etc., to increase the cleaning effect, clean up, and facilitate The effect of using

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

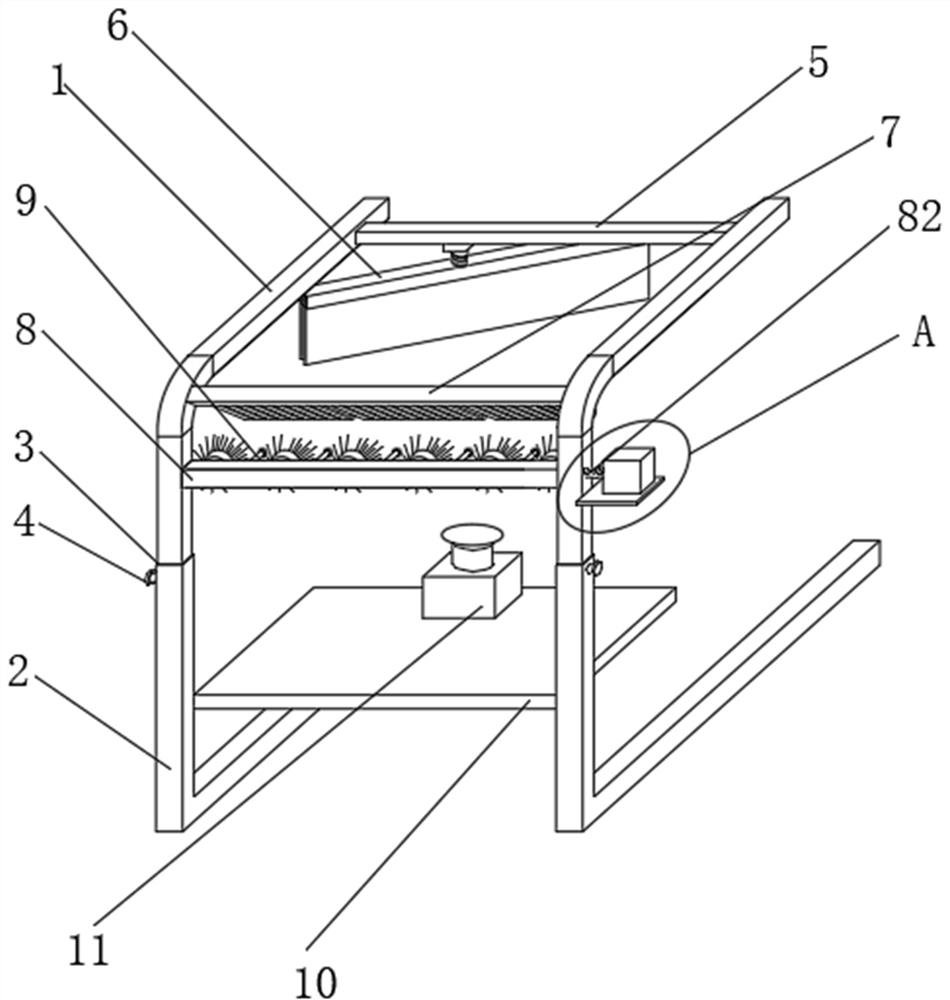

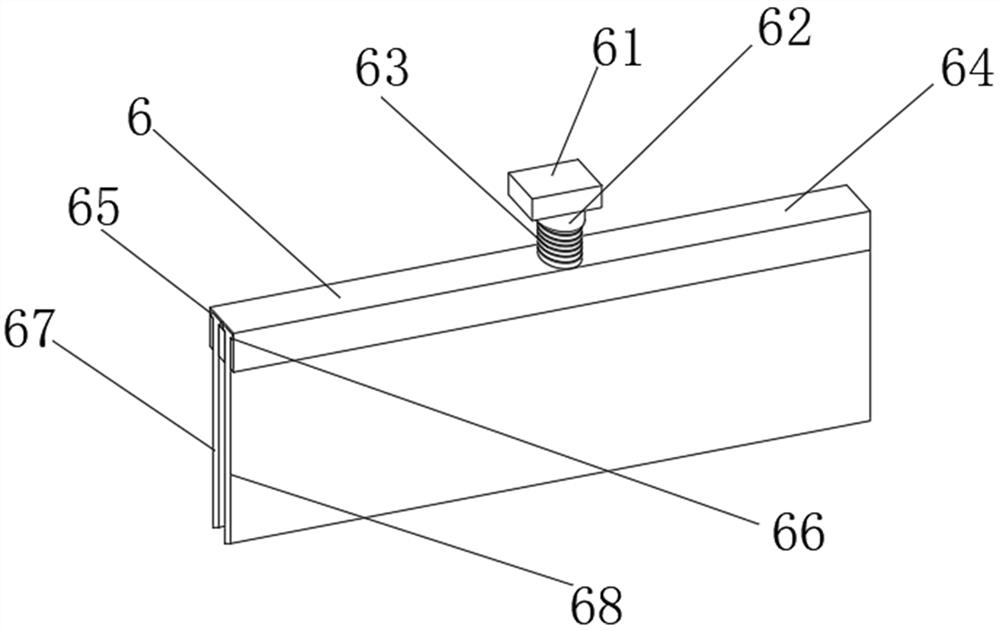

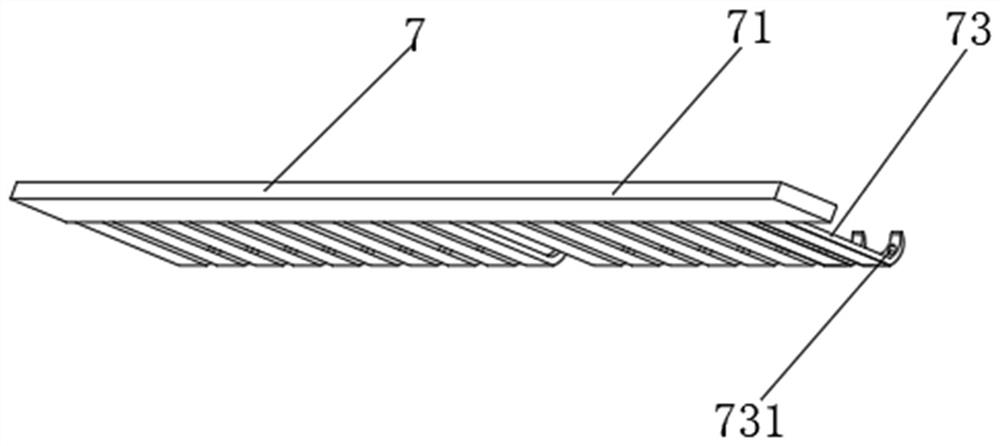

[0030] Such as Figure 1-7 As shown, a conveyor protection and control device for coal mines includes two sets of upper support frames (1) and two sets of lower support frames (2). The upper end of the lower support frames (2) is provided with an installation channel (3). The lower end of the frame (1) is inserted into the inside of the installation channel (3) of the lower support frame (2), and a fixing bolt (4) is provided on one side of the lower support frame (2) close to the installation channel (3), which is characterized in that: The first support installation plate (5) is fixedly connected between the two sets of upper support frames (1), and the lower end of the first support installation plate (5) is provided with a first cleaning module (6), which is located on the first support installation plate (5). ) is provided with a second cleaning module (7) between the two sets of upper support frames (1) on one side, and a third cleaning module ( 8), by inserting the low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com