Bag removal mechanism, device and method

A technology of motion mechanism and mounting parts, which is applied in the direction of conveyor, unstacking, transportation and packaging of objects, and can solve problems such as high labor intensity, poor versatility, and harsh working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

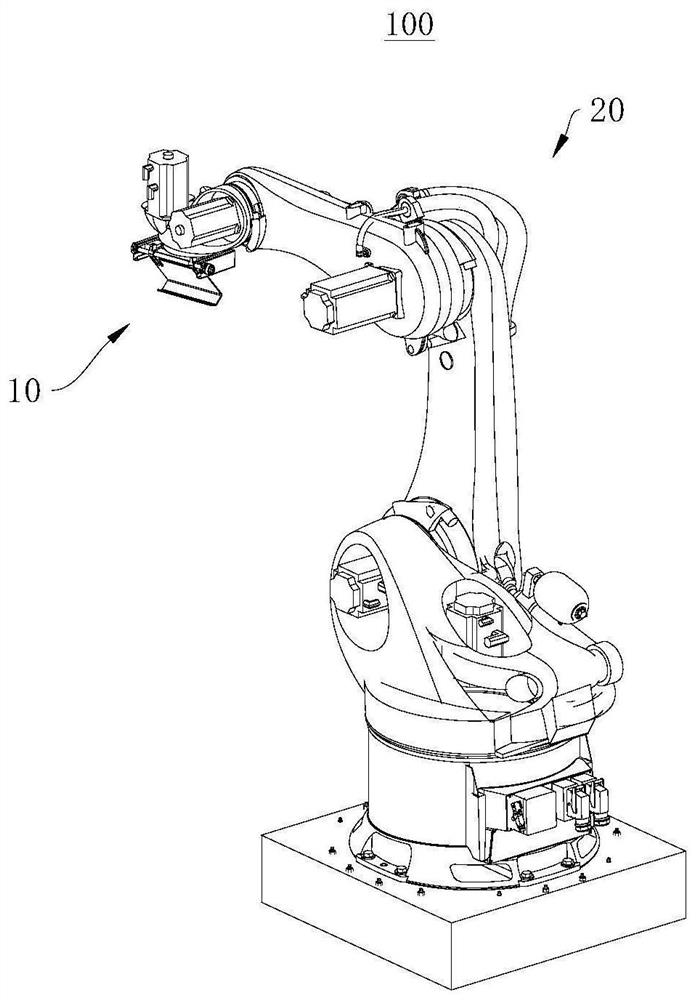

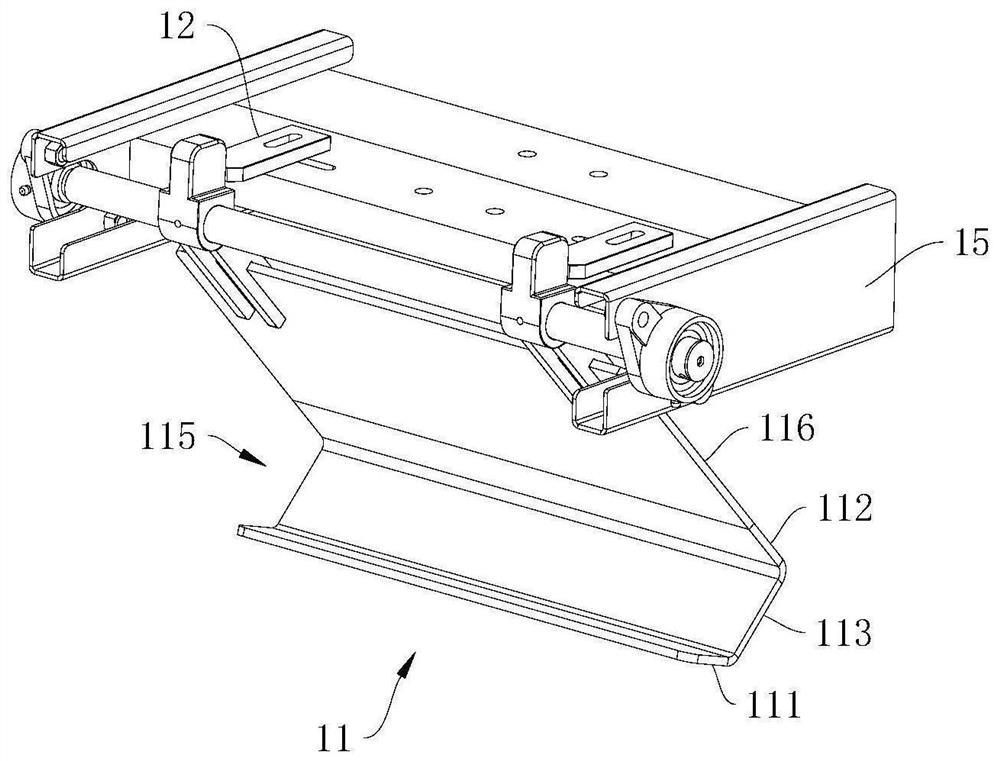

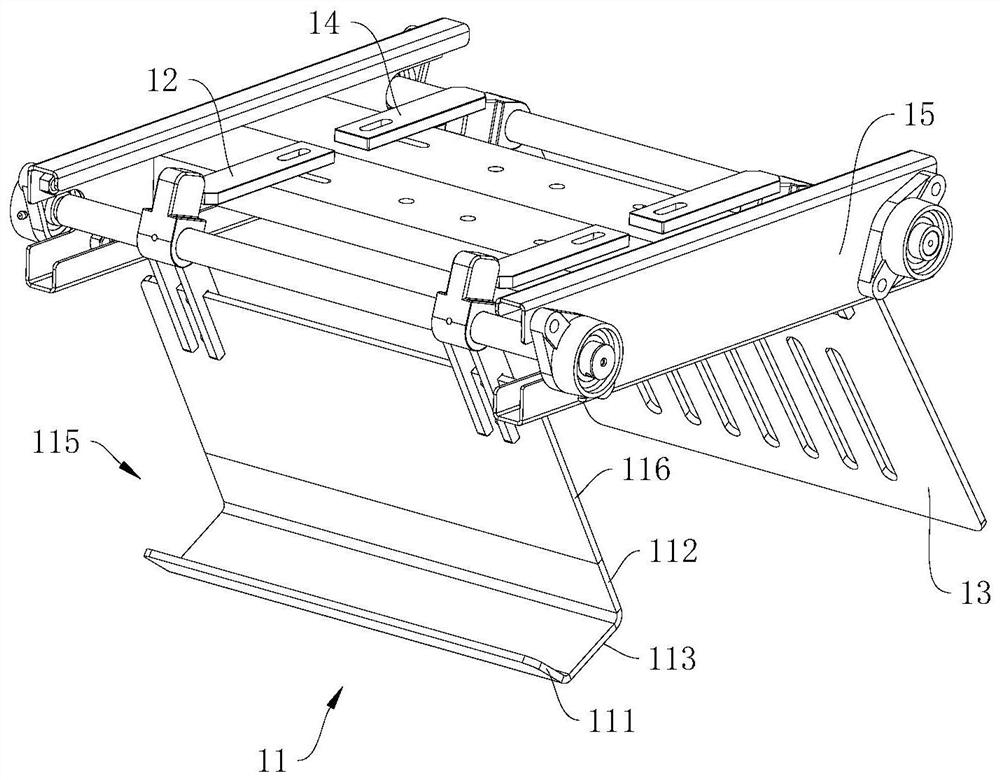

[0040] see figure 1 , figure 1 It is a structural schematic diagram of the bag unpacking mechanism 10 applied to the bag unpacking device 100 provided by the first embodiment of the present invention.

[0041] The first embodiment of the present invention provides a bag unpacking mechanism 10. The bag unpacking mechanism 10 is used for unpacking a stack of goods 900, especially a stack of goods 900 containing bagged goods 910. The bag unpacking mechanism 10 has relatively stable bag unpacking, And the characteristics of better versatility. The bag unpacking mechanism 10 can be applied to scenarios such as bag unpacking device 100 , unstacking system, automated warehouse, logistics system, or automated factory.

[0042] Taking the bag unpacking mechanism 10 applied to the bag unpacking device 100 as an example, the bag unpacking device 100 can include a bag unpacking mechanism 10 and a bag unpacking motion mechanism 20, the bag unpacking mechanism 10 is connected to the bag u...

no. 2 example

[0076] see Figure 7 , Figure 7 It is a schematic flowchart of the bag unpacking method provided by the second embodiment of the present invention.

[0077] The second embodiment of the present invention provides a bag unpacking method, which also has the characteristics of relatively stable bag unpacking and good versatility. This bag unpacking method can be applied to the above-mentioned bag unpacking device 100 . It should be noted that the basic principles and technical effects of the bag-unpacking method provided in this embodiment are the same as those of the above-mentioned embodiment. Corresponding content.

[0078] When the bag opening device 100 does not include the second bag opening member 13, the bag opening method may include:

[0079] Step S101: The bag unpacking movement mechanism 20 drives the mounting part 15 to move, so that the first hooking section 111 rests on the top of the cargo stack 900 and slides along the top of the cargo stack 900, and makes t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com