Special lifting hook for U-shaped rib

A hook and U-shaped technology, applied in the field of steel component hoisting equipment, can solve the problems of narrow width, affecting component quality, deformation of steel structure components, etc., to achieve the effect of reducing deformation, scientific and reasonable design, and ensuring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

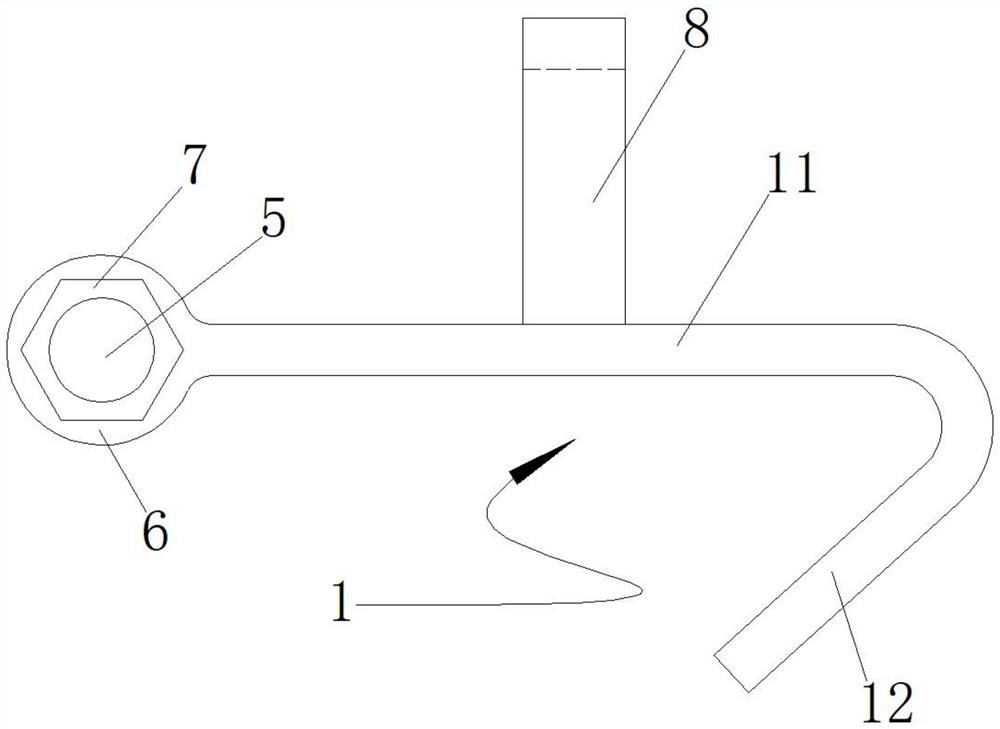

[0027] Example 1, such as Figure 1-4 As shown, a U-shaped rib special hook provided in this embodiment includes a hook body 1 formed by bending a steel plate for hooking a steel member 4, a wire rope installation mechanism is provided on the hook body 1, and the hook body 1 passes through The wire rope installation mechanism is installed on the crane wire rope 3, and the width of the hook body 1 is 10-35cm.

[0028] The invention is simple in structure, scientific and reasonable in design, and easy to use. It can effectively increase the contact area between the hook and the steel component when hooking the steel component, thereby reducing the deformation of the steel component and ensuring the quality of the steel component after hoisting. The invention is especially suitable for U-shaped ribs for hoisting hooks.

Embodiment 2

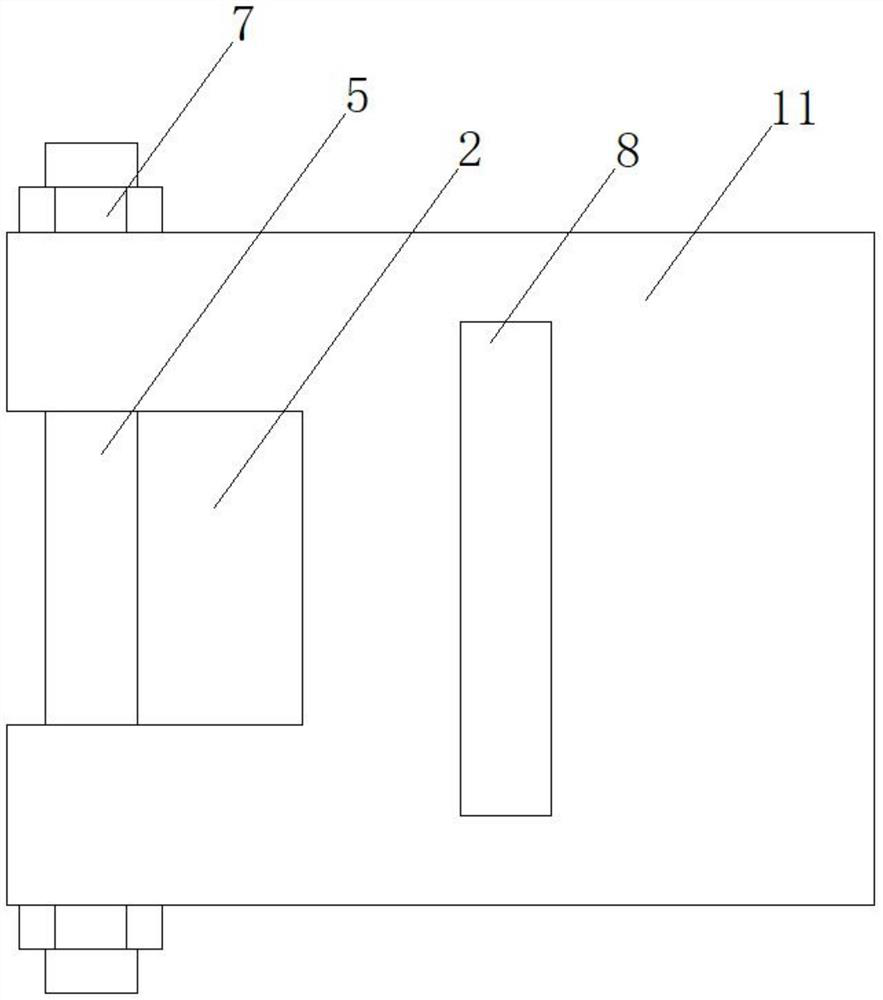

[0029] Example 2, such as Figure 1-4 As shown, a U-shaped rib special hook provided in this embodiment includes a hook body 1 formed by bending a steel plate for hooking a steel member 4, a wire rope installation mechanism is provided on the hook body 1, and the hook body 1 passes through The wire rope installation mechanism is installed on the crane wire rope 3, and the width of the hook body 1 is 10-35cm. The wire rope installation mechanism includes a U-shaped groove 2 opened on the hook body 1, and a screw rod 5 detachably installed on the hook body 1 to close the opening of the U-shaped groove 2. The crane wire rope 3 is passed through the U-shaped groove 2 and bolted Hang on the screw 5.

[0030] On the basis of Example 1, this embodiment provides the specific structure of the wire rope installation mechanism. The wire rope installation mechanism includes a U-shaped groove 2 opened on the hook body 1, and a U-shaped groove 2 that is detachably installed on the hook bod...

Embodiment 3

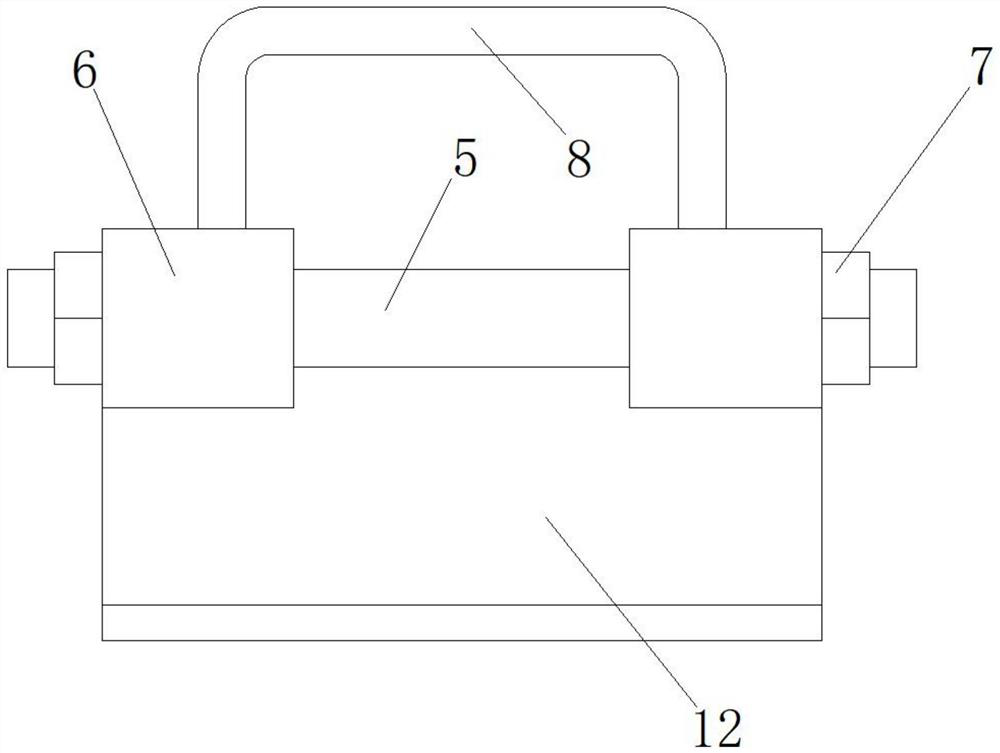

[0031] Example 3, such as Figure 1-4 As shown, a U-shaped rib special hook provided in this embodiment includes a hook body 1 formed by bending a steel plate for hooking a steel member 4, a wire rope installation mechanism is provided on the hook body 1, and the hook body 1 passes through The wire rope installation mechanism is installed on the crane wire rope 3, and the width of the hook body 1 is 10-35cm. The wire rope installation mechanism includes a U-shaped groove 2 opened on the hook body 1, and a screw rod 5 detachably installed on the hook body 1 to close the opening of the U-shaped groove 2. The crane wire rope 3 is passed through the U-shaped groove 2 and bolted Hang on the screw 5. The hook body 1 is provided with a sleeve 6 adapted to the screw rod 5 , and the screw rod 5 passes through the sleeve 6 and is locked by a nut 7 .

[0032] On the basis of Example 1, this embodiment further provides the specific structure of the wire rope installation mechanism. The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com