Transition piece for surface casing feeding based on non-drilling machine time well cementation and feeding method

A technology of surface casing and large and small heads, which is applied in drilling equipment and methods, drill pipes, casings, etc., can solve the problems of high driller experience requirements and difficult tripping of large and small heads, and achieves reduction of the difficulty of making and breaking. The effect of improving efficiency and reducing technical difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

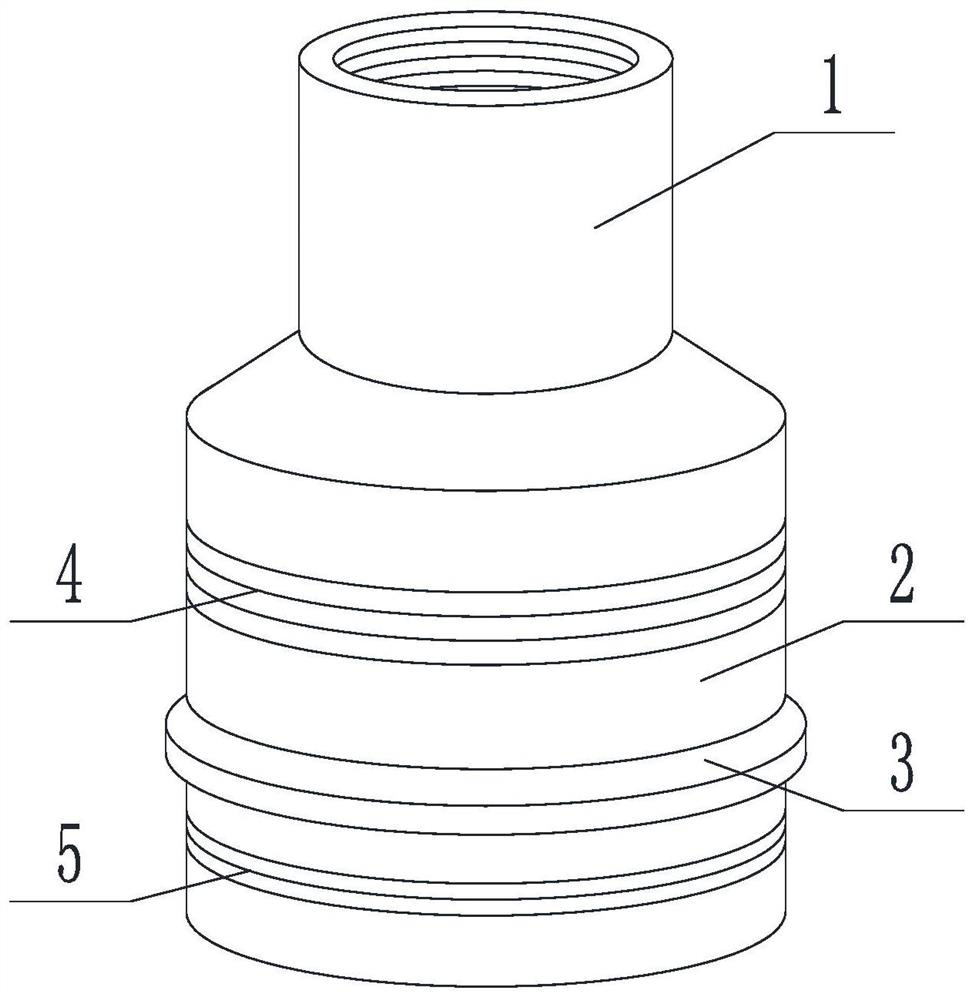

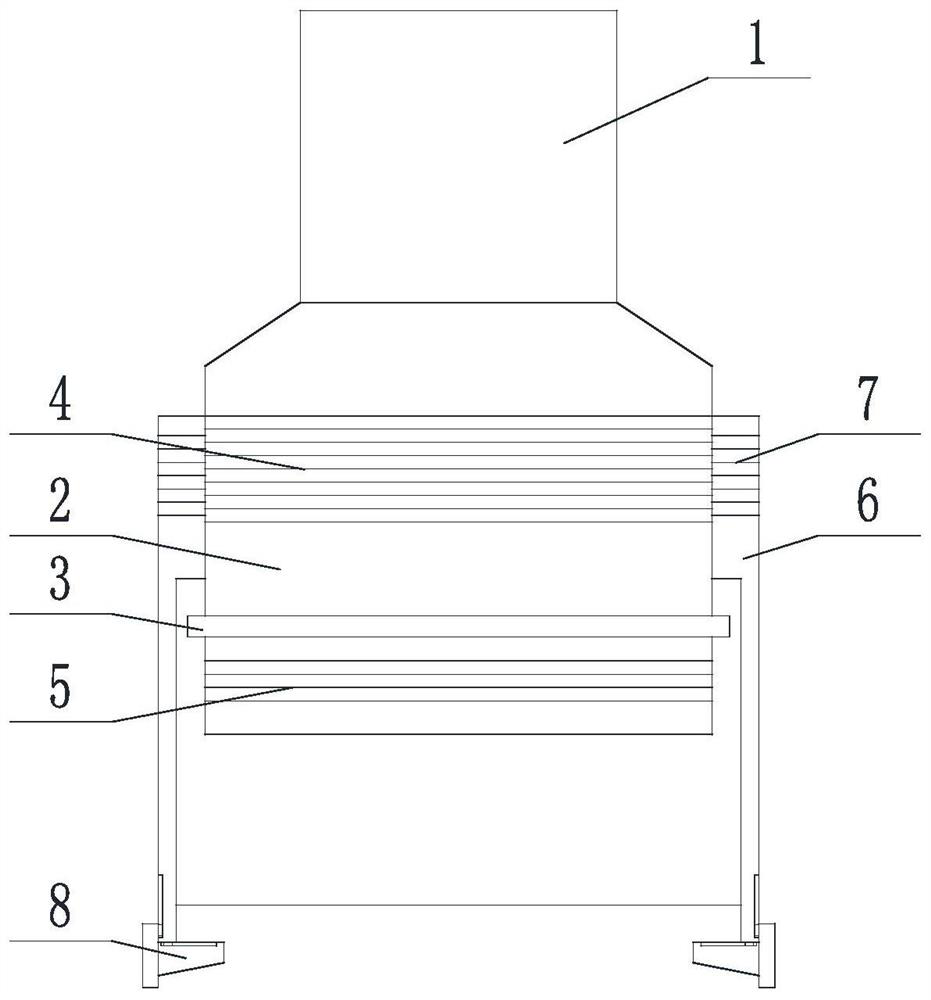

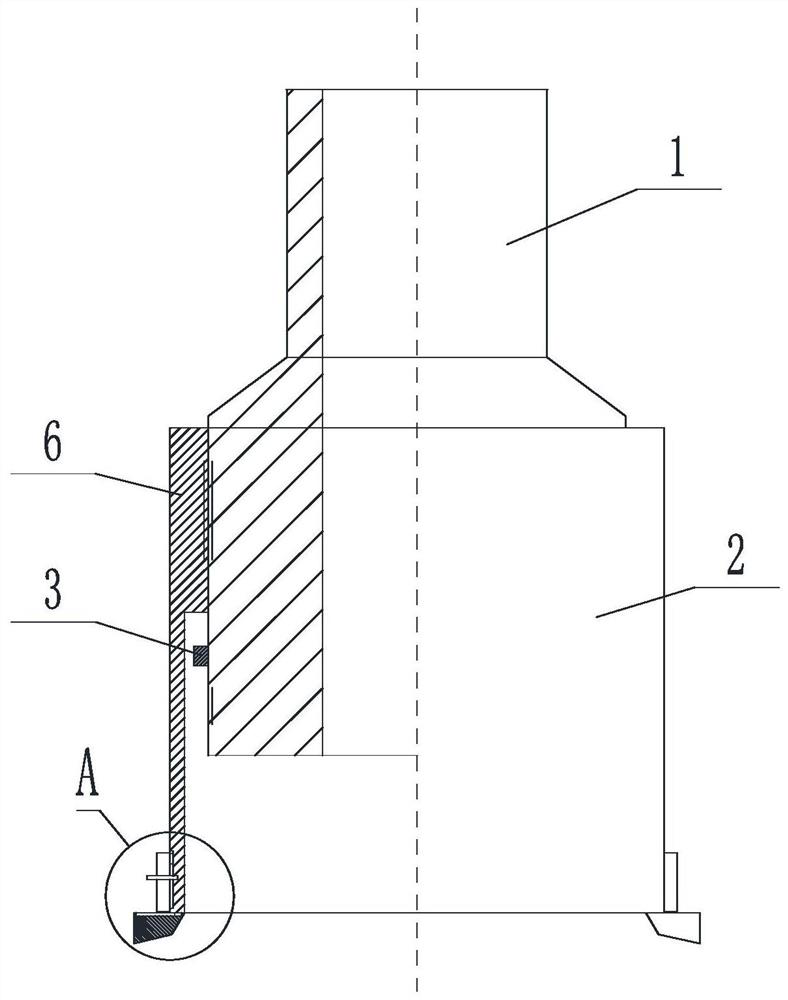

[0042] Such as Figure 1 to Figure 8 The upper and lower heads for surface casing feeding based on non-drilling time cementing shown include the upper and lower drill pipe connecting parts 1 and casing connecting parts 2, and the casing connecting parts 2 are arranged in sequence from top to bottom. Threaded section 1 4, convex ring 3, external threaded section 2 5, external threaded section 2 5 is matched with the casing box to be connected; it also includes a sleeve 6 sleeved outside the casing connecting portion 2, and the sleeve 6 The inner wall is provided with an internal thread segment 7 that matches the external thread segment 1, and the bottom of the sleeve 6 is provided with a number of annularly distributed supporting components; when the top surface of the connected casing collar contacts the bottom surface of the convex ring 3, the external thread segment Two 5 are threadedly connected with the connected casing box, and the supporting component supports the bottom...

Embodiment 2

[0053] On the basis of Embodiment 1, the supporting assembly includes a supporting block 8 slidably connected to the bottom of the sleeve 6 , and the supporting block 8 can slide along the radial direction of the sleeve 6 . A chute-9 is provided on the top surface of the supporting block 8, and a slide block-10 matched with the chute-9 is provided at the bottom of the sleeve 6; the axis of the chute-9 is perpendicular to the axis of the sleeve 6. It also includes a block 11 for preventing the radially outward sliding of the supporting block 8; the blocking block 11 corresponds to the supporting block 8 one by one. Slider 2 12 is set on the block 11 , and the outer wall of the sleeve 6 is provided with a chute 2 13 matched with the slider 2 12 , and the axis of the chute 2 13 is parallel to the axis of the sleeve 6 .

[0054] In this embodiment, the usage method of the supporting component includes:

[0055] When the bottom end of the casing collar 15 needs to be supported by ...

Embodiment 3

[0058] On the basis of Embodiment 2, the bottom surface of the supporting block 8 is gradually inclined downward along the radial direction outward; ; When the support block 8 slides to the outermost side, the inner end of the support block 8 is flush with the inner wall of the sleeve 6; flush.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com