An elastic clamping positioning mechanism for the inner tube assembly of a rope core drilling tool

A core drilling tool and assembly ejection technology, which is applied in the direction of extracting undisturbed core devices, earthwork drilling and mining, etc., can solve the problems of reduced reliability of salvage, failure of salvage of inner pipe assembly, and increase of drilling cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

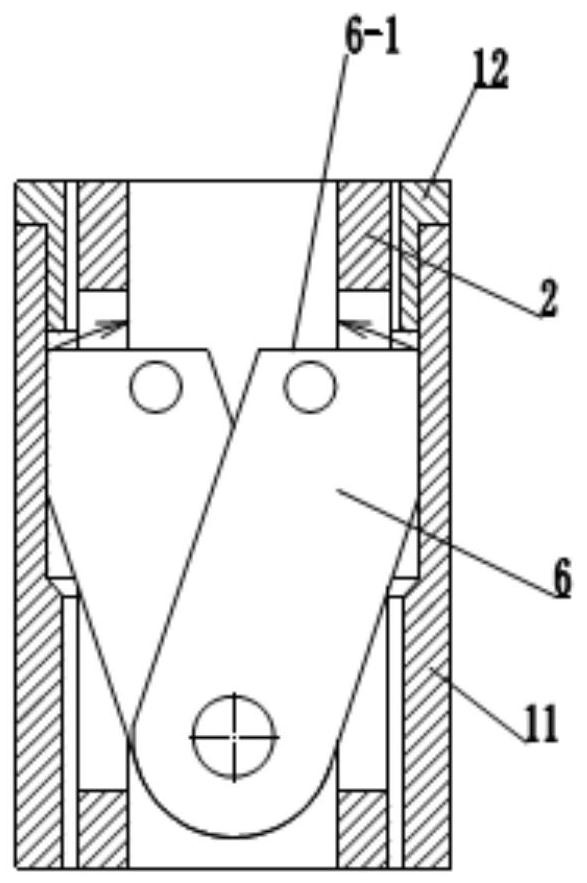

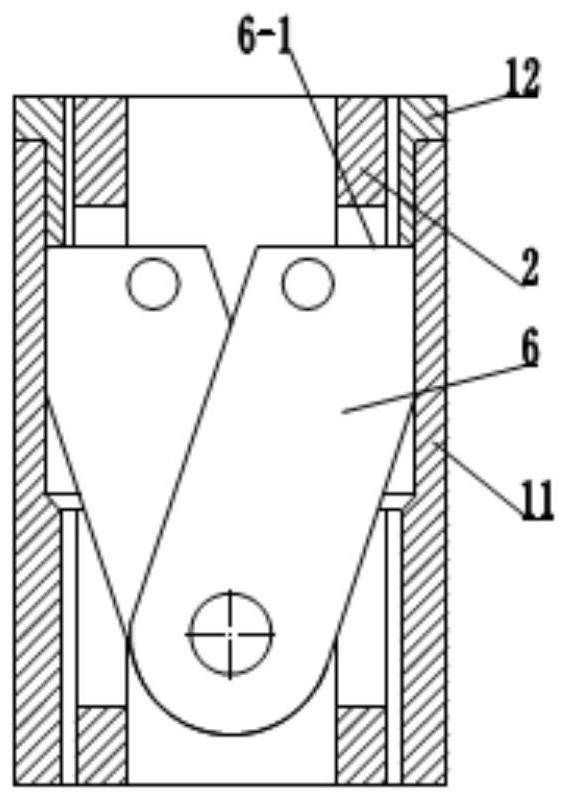

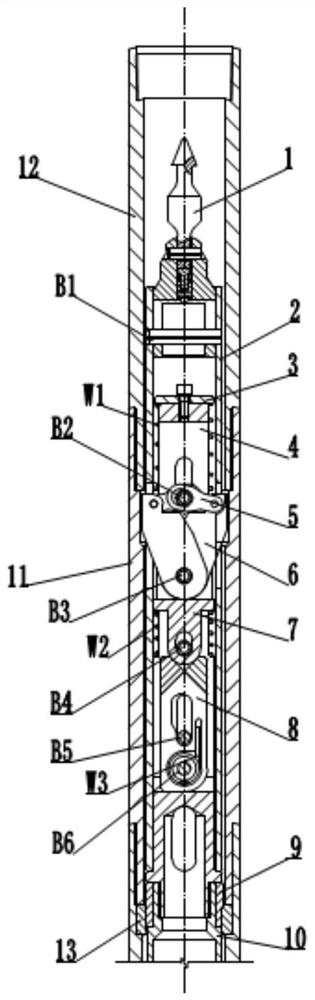

[0044] see image 3 , during the normal drilling process of the cable core drilling tool, the inner tube assembly is mounted on the seat ring 13 of the outer tube assembly through the suspension ring 9 embedded between the cartridge holder 4 and the water distribution jacket 10. The invention provides a snap positioning mechanism for the inner tube assembly of a rope core drilling tool, which includes a recovery pipe 2, a snap frame 4, a snap stop block 5, a snap caliper 6, a snap seat 7 and a support plate 8 The upper end of the recovery pipe 2 and the spear head assembly 1 of the inner pipe assembly are hingedly assembled through the elastic cylindrical pin B1, and the cartridge holder 4 is set in the recovery pipe 2, and two spring calipers are symmetrically arranged on the side wall of the recovery pipe to avoid Holes 2-3; the cartridge ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com