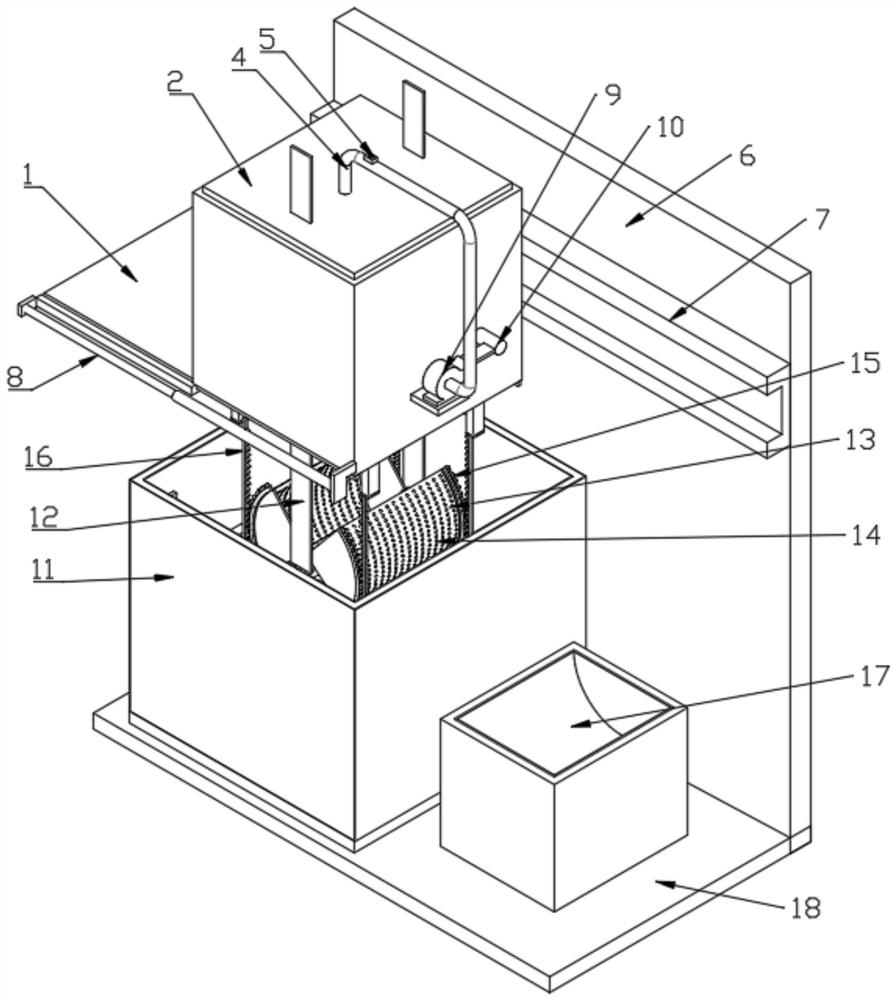

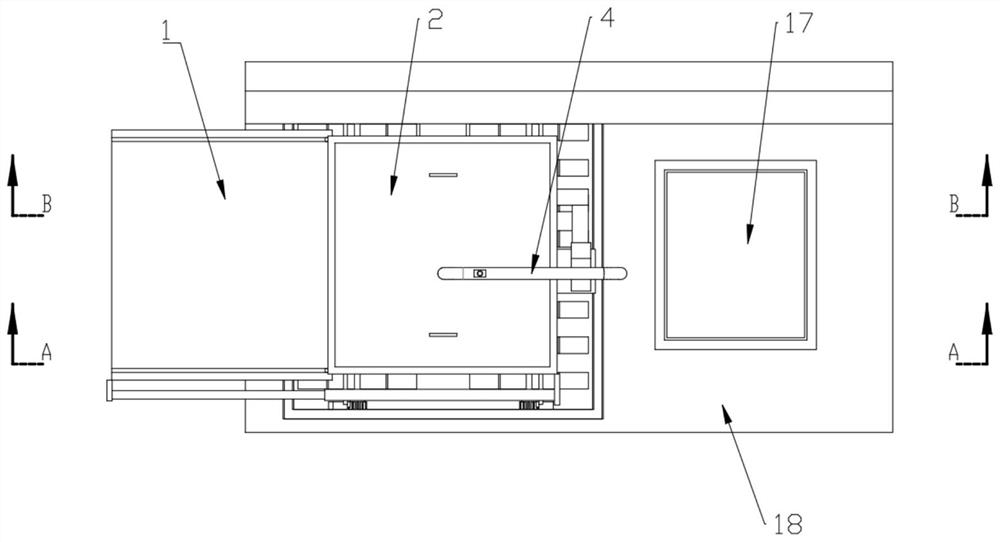

Production device of building heat preservation vacuum insulation panel core material

A technology of vacuum insulation panels and production equipment, which is applied in the directions of transportation and packaging, dissolving, mixing machines, etc., which can solve the problems of non-planar non-planar fields, the inability to ensure uniform slurry composition, and complicated operation steps, so as to avoid Adverse effects, improving dehydration efficiency and quality, and improving the effect of salvage quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

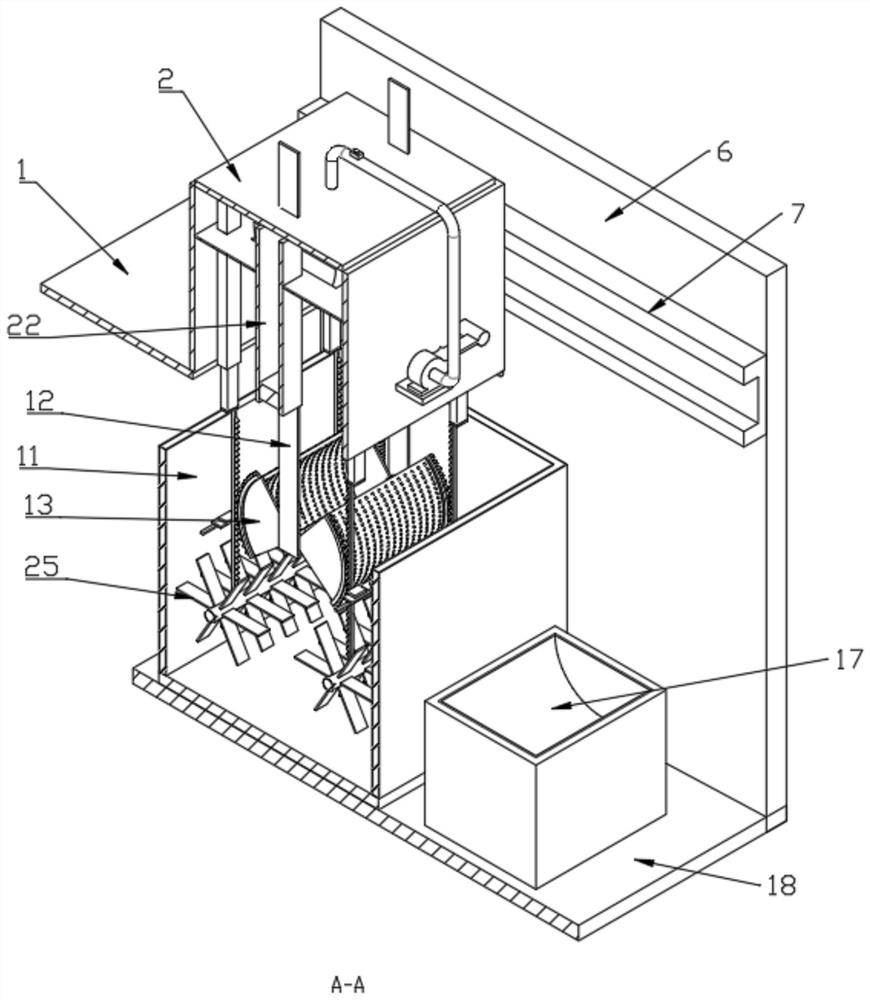

[0042] Embodiment 1, an embodiment for driving two stirring rods 25 to rotate, the inner wall of the slurry tank 11 is fixedly equipped with an engagement mechanism for driving the rotation of the two stirring rods 25, and the engagement mechanism includes The fixed bar 27 on the inner wall, the movable block 29 is slidably installed on the fixed bar 27, the first spring 28 is connected between the movable block 29 and the bottom of the fixed bar 27, the first spring 28 is fixed on the movable block 29, the stirring rod 25 The outer wall is distributed with the second teeth 33 meshed with the second rack 26, the top of the second rack 26 is fixedly connected with the extension block 30, and the side wall of the first rack 16 is fixedly installed with a press for pressing the extension block 30. Block 31.

[0043] Through the agitating mechanism provided, when the vertical bar 12 moves downwards, the first rack 16 can be further moved downward, and when the pressing block 31 co...

Embodiment 2

[0044] Embodiment 2, another embodiment for driving two stirring rods 25 to rotate, further, two motors 32 are fixedly installed on the outer wall of the slurry tank 11, and the two motors 32 are used to drive the two stirring rods 25 Opposite rotation occurs.

[0045] Through the two motors 32 provided, the two motors 32 can be driven to rotate in different directions, and the slurry inside the slurry tank 11 can be agitated by turning to avoid its settlement.

[0046] Further, a receiving box 17 for receiving materials is fixedly installed on the upper surface of the bottom plate 18 .

[0047] When the dehydration box 2 is located directly below the receiving box 17, the electric telescopic rod 8 drives the sealing plate 1 to open again. Similarly, when the vertical bar 12 drives the arc-shaped mold cover 13 to move downward, the first tooth bar 16 and the second tooth bar 16 move downward. Under the meshing drive of one tooth 15, the two arc-shaped mold sets 13 are gradual...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com