A core tube check valve mechanism of a wireline coring tool

A technology for coring drilling tools and core pipes, which is applied in the direction of extracting undisturbed core devices, borehole/well valve devices, earth cube drilling and production, etc., which can solve the problems of reducing work efficiency, increasing the difficulty of core extraction and operating time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

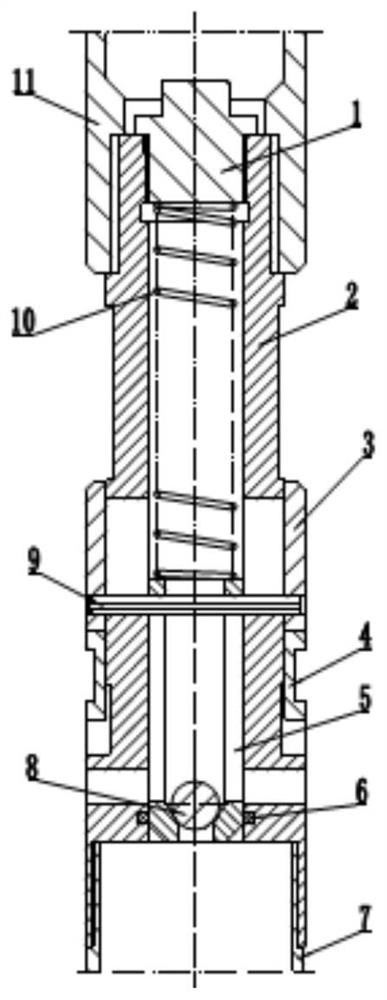

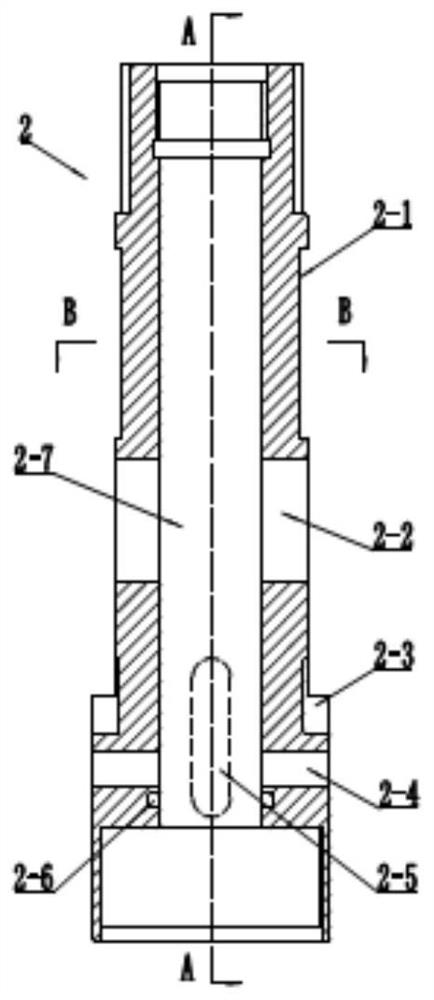

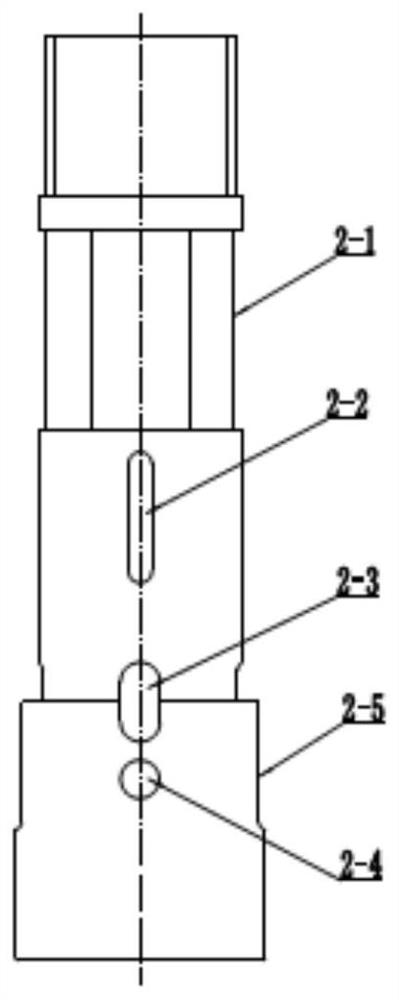

[0039] see figure 1 , figure 2 , image 3 , Figure 5 , Image 6 , Figure 9 , Figure 10 , the core pipe one-way valve mechanism of the cable coring drilling tool according to the present invention, comprising a core pipe joint 2, a thrust sleeve 3, a liftable valve seat 5, a cylindrical pin 9 and a steel ball 8; the core pipe joint 2 There is an inner hole 2-7 through up and down and a drain hole 2-4 vertically through the inner hole, and a sealing ring groove 2-6 is arranged at the bottom of the inner hole 2-7 of the core pipe joint 2, and a An elastic sealing ring 6 is installed in the ring groove 2-6, and the upper and lower ends of the core pipe joint 2 are respectively assembled with the connecting sleeve 11 of the inner pipe assembly of the rope core drilling tool and the core pipe 7 through a threaded connection structure, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com