A Radial Sealing System Fitting Contact Air Preheater

A technology of radial sealing and air preheater, which is applied in the direction of engine sealing, indirect carbon dioxide emission reduction, combustion method, etc. Influence, reduce radial air leakage, improve unit efficiency and the effect of economical operation level of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

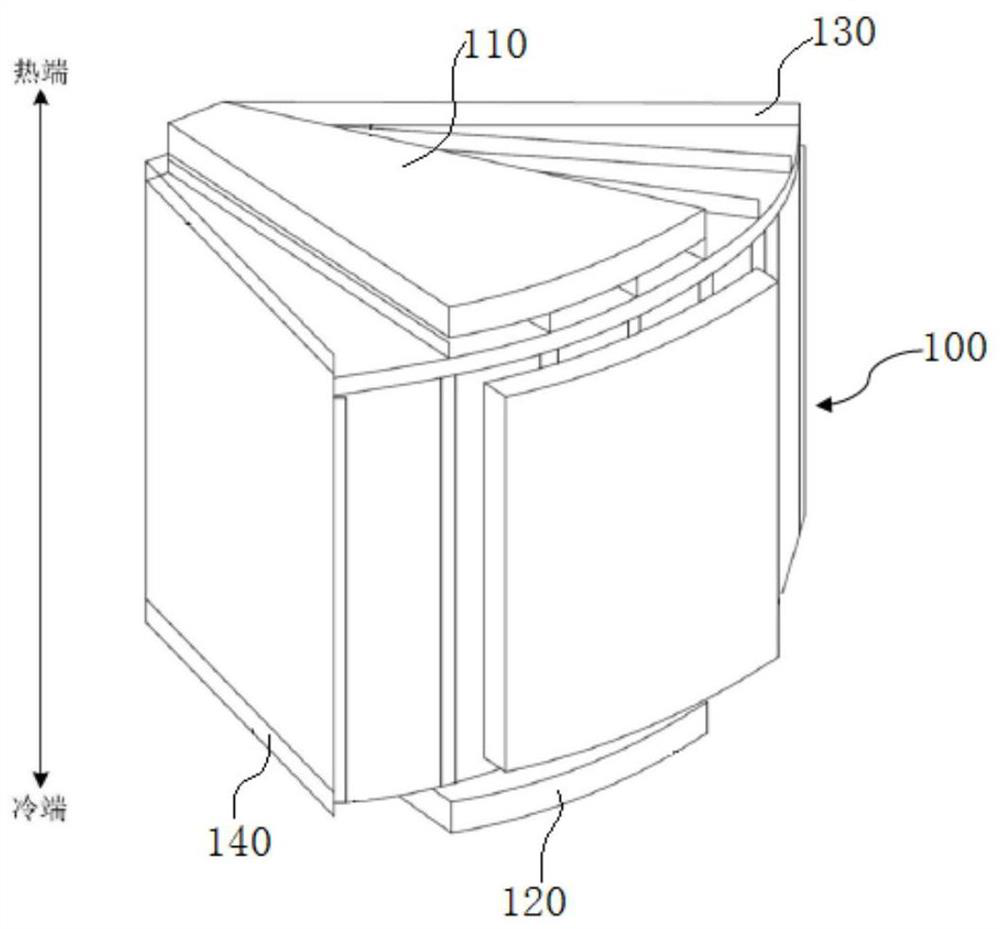

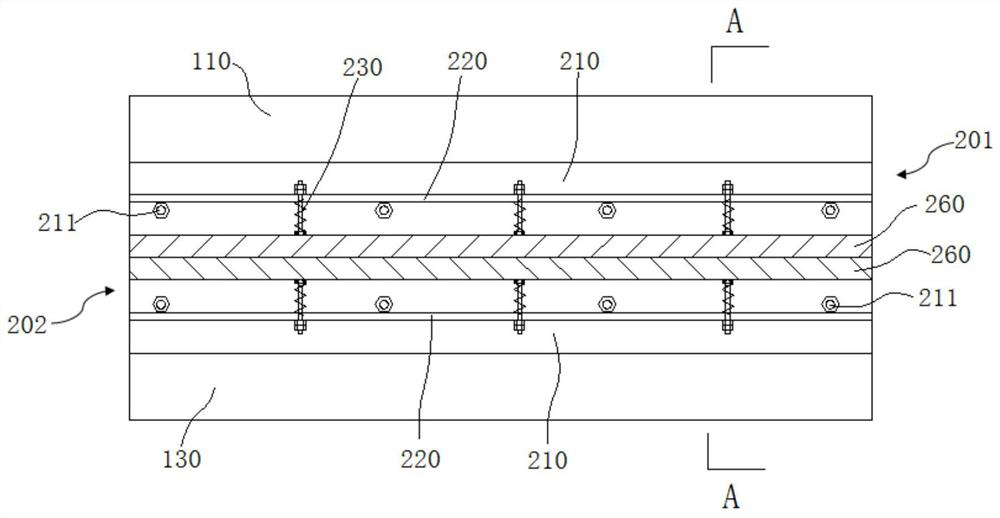

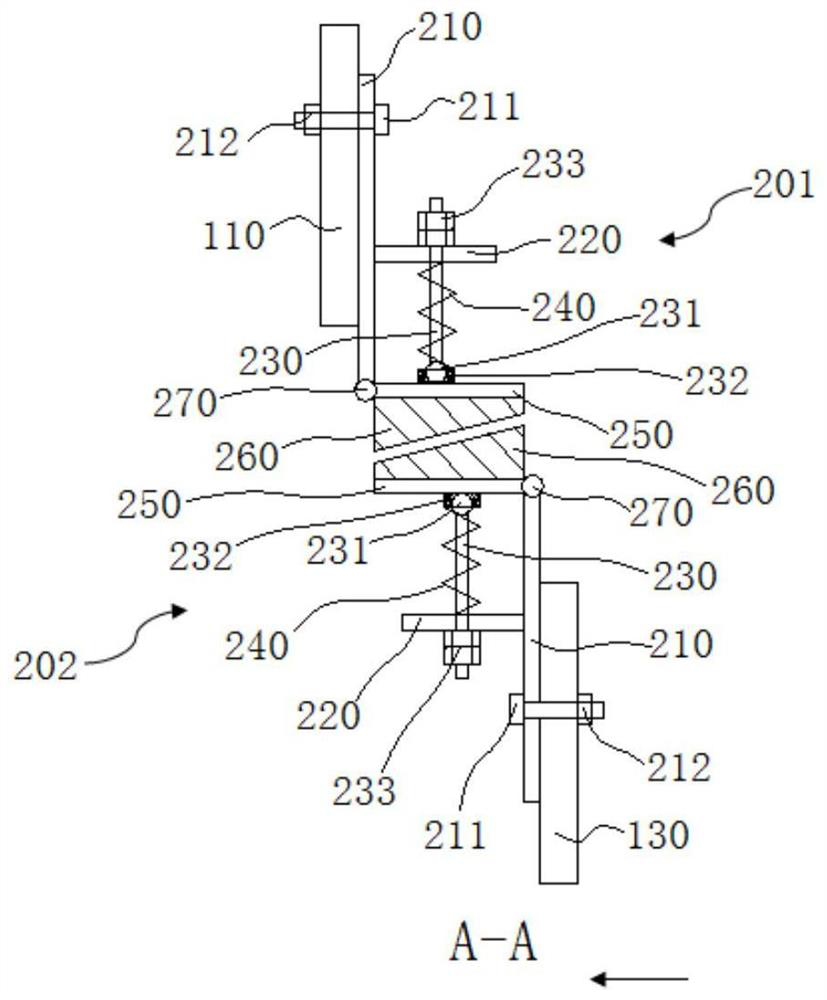

[0037] combine Figure 1-Figure 3 , a radial sealing system of a fitted contact type air preheater in this embodiment includes a radial sealing device 200 arranged between the hot end sector sealing plate 110 and the hot end radial partition plate 130 of the rotor 100. The radial sealing device 200 includes an upper sealing unit 201 arranged at the lower part of the hot end fan-shaped sealing plate 110 and a lower sealing unit 202 arranged at the lower part of the hot end radial partition plate 130. The upper sealing unit 201 and the lower sealing unit 202 have the same structure and are symmetrically distributed , the bottom of the upper sealing unit 201 and the top of the lower sealing unit 202 form a mutual fit, and are sealed in pairs, so that the sealing gap of the air preheater can be effectively compensated under the mushroom-shaped deformation state, so as to ensure that the air preheater is still under full load operation. It can ensure a good sealing effect, effectiv...

Embodiment 2

[0043] The radial sealing system of a contact-type air preheater in this embodiment is basically the same in structure as in Embodiment 1. Further, this embodiment also includes a fan-shaped sealing plate 120 disposed on the cold end of the rotor 100 and a diameter of the cold end. The radial sealing device 200 between the partition plates 140 is the same in structure as the radial sealing device 200 disposed between the hot end sector sealing plate 110 and the hot end radial partition plate 130 of the rotor 100, which not only ensures the hot end sector The sealing effect of the sealing plate 110 can also improve the sealing effect of the fan-shaped sealing plate 120 at the cold end of the air preheater, further reducing the air leakage rate of the air preheater, improving the efficiency of the boiler, and reducing the production cost.

[0044] In this embodiment, the hot-end fan-shaped sealing plate 110 and the fixing plate 210 are provided with connecting holes at the corres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com