Power oil discharge and nitrogen injection device of extra-high voltage converter transformer, control system and control method

An oil discharge device, oil discharge and nitrogen injection technology, which is applied in the direction of transformer/inductor cooling, transformer/inductor parts, electrical component structure association, etc., can solve the problem of long oil discharge time, reduce fire extinguishing efficiency, and apply The effect of widening the area and reducing the risk of fire out of control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

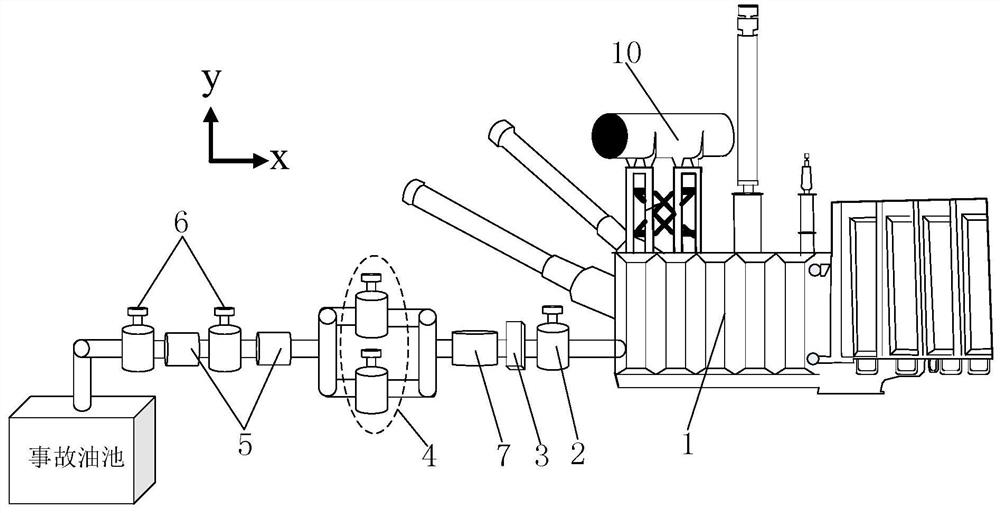

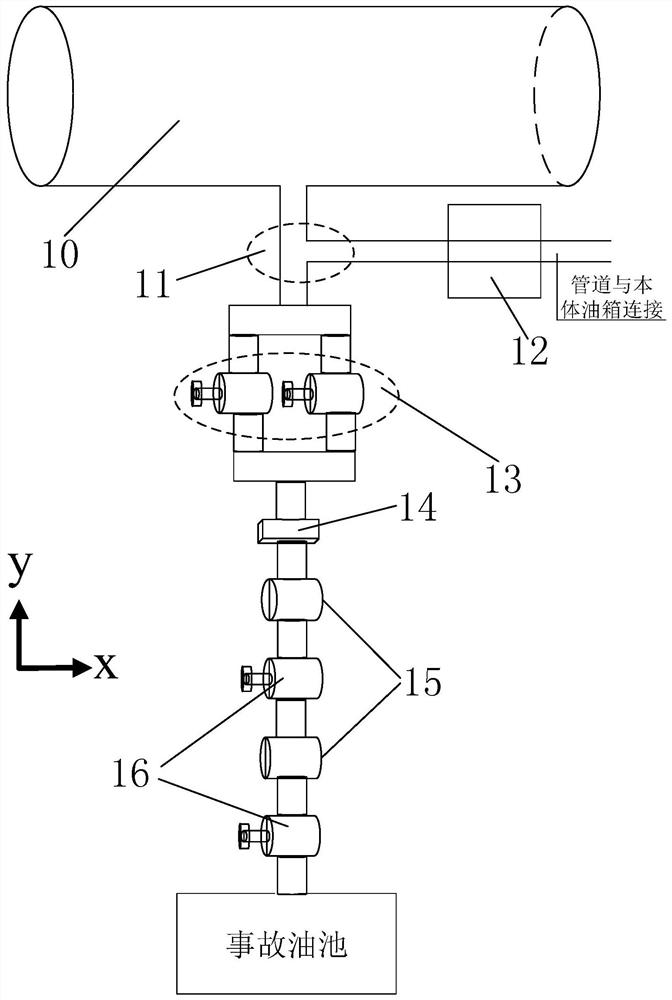

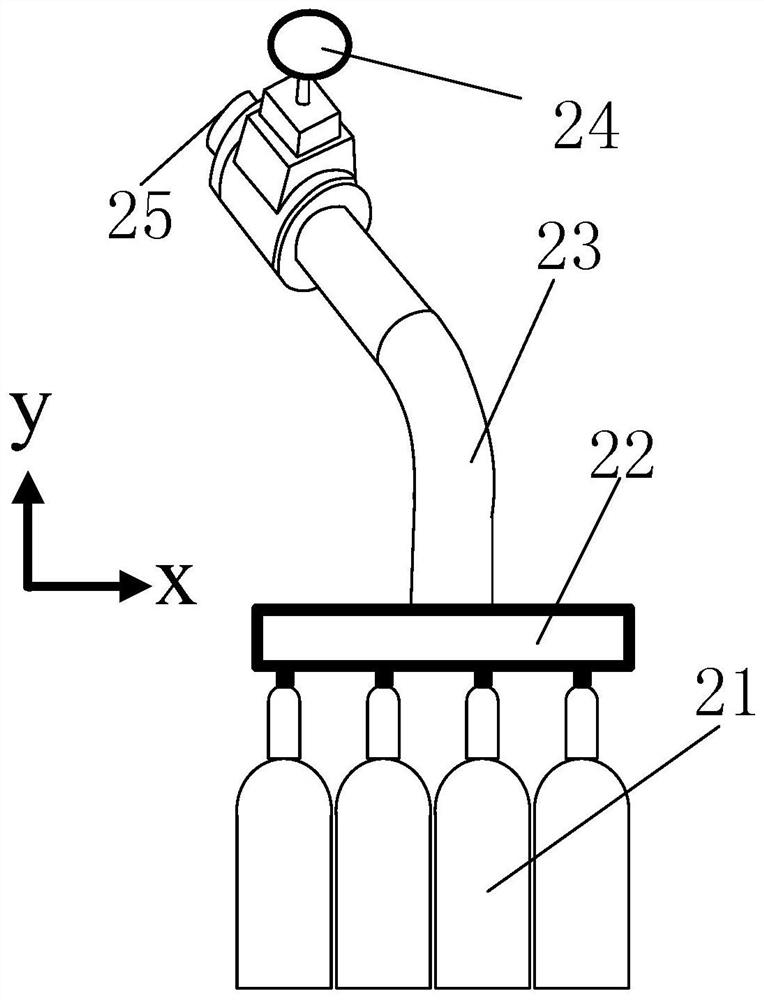

[0074] Such as Figure 1-3 As shown, the UHV converter variable power oil discharge and nitrogen injection device includes the body oil tank 1, the inspection valve 2, the first oil flow meter 3, the oil pump 7, the first dual-type electric valve group 4, and multiple body oil tank leakage alarms instrument 5, multiple body oil tank butterfly valves 6, emergency oil pools, oil storage tanks 10, body three-way valves 11, cut-off valves 12, second dual configuration electric valve group 13, second oil flow meters 14, multiple storage tanks Oil tank leakage alarm 15, multiple oil storage tank butterfly valves 16, multiple nitrogen injection devices.

[0075] The first port of the body three-way valve 11 is connected to the oil storage tank 10 through the oil discharge pipe of the deflagration-resistant flame arrester, and the second port is connected to the second dual-configuration electric valve group 13 through the oil discharge pipe of the deflagration-resistant flame arreste...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap