Linear comb tooth electric heating hair straightening comb

A straight-line, comb-tooth technology, applied in the field of straight-line comb-tooth electric heating hair straightening combs, can solve the problems of increased resistance, no opening effect, increased advance resistance, etc., and achieves large overall friction, good opening effect, The effect of simplifying the operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below with reference to the drawings and specific embodiments.

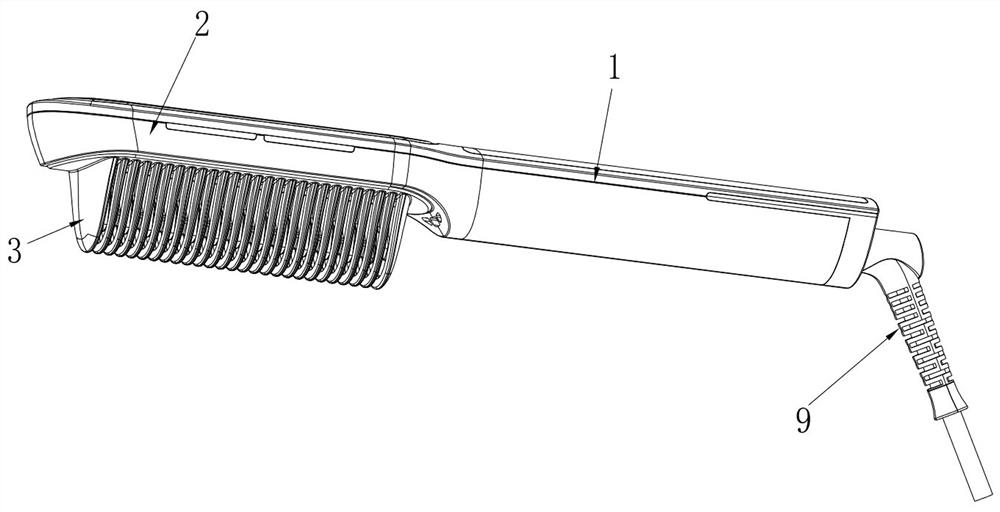

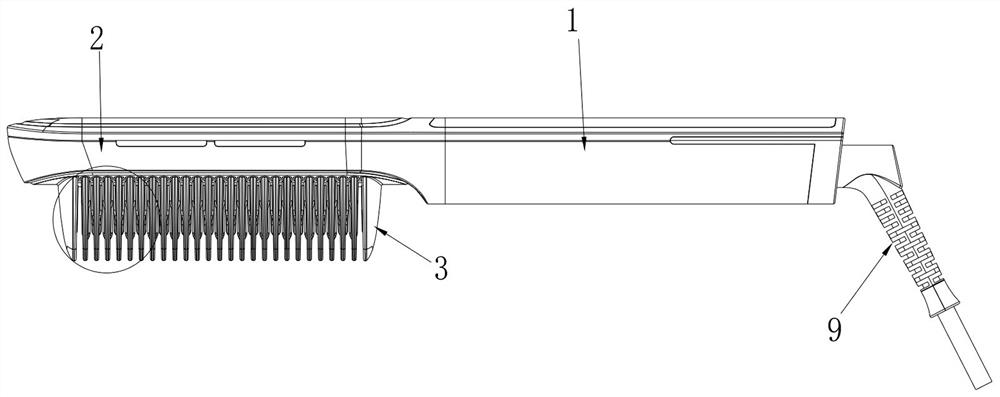

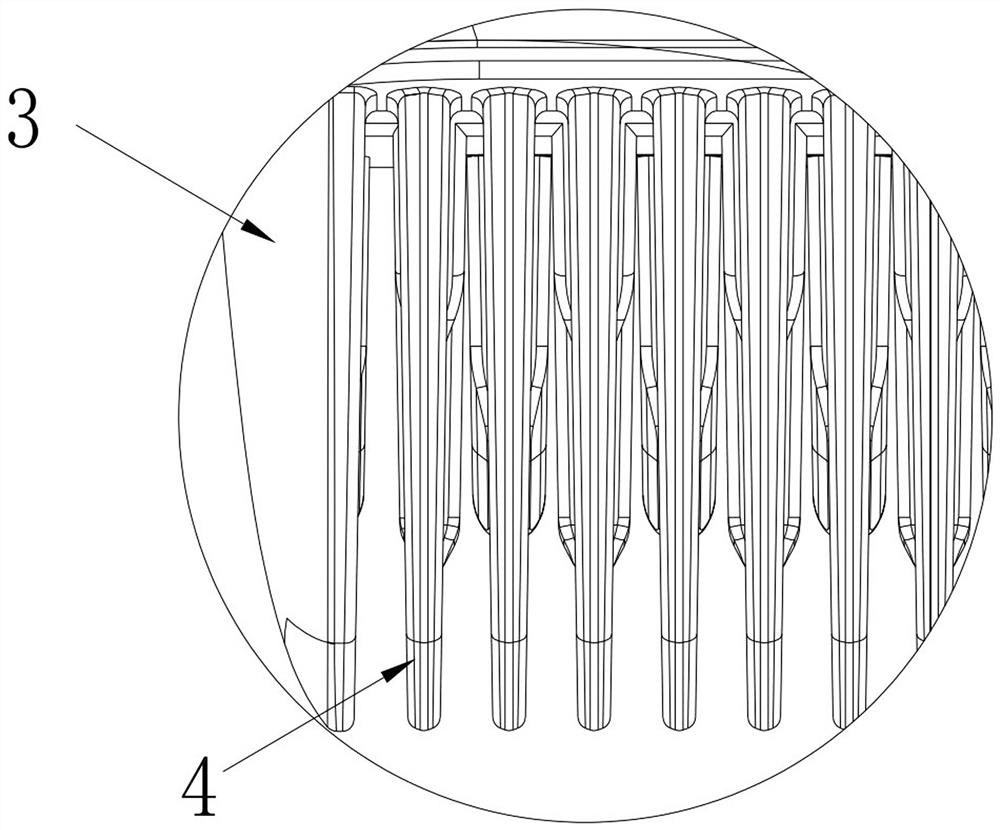

[0029] In this embodiment, refer to Figure 1-Figure 10 , The linear comb-tooth electric heating straight hair comb specifically implemented includes a housing and an electric control assembly arranged in the housing. One end of the housing is a handle 1. The electric control assembly includes a heating device, a thermistor 8, and a main control board. 7 and the power supply, the heating device, the thermistor 8 and the power supply are all electrically connected to the main control board 7. The main control board 7 is arranged inside the handle 1, and the main control board 7 is provided with a main control button and a display screen. The buttons and the display screen extend to the surface of the handle 1, and the surface of the handle 1 is provided with a lens 16 for covering the main control buttons and the display screen. The power cord 9 is fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com