Gradeable intelligent sand making machine

A sand making machine, an intelligent technology, applied in the direction of grain processing, etc., can solve the problems of raw material classification processing, reducing work efficiency, sand making machine stuck, etc., to achieve the effect of enhanced crushing effect, high work efficiency, and enhanced stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

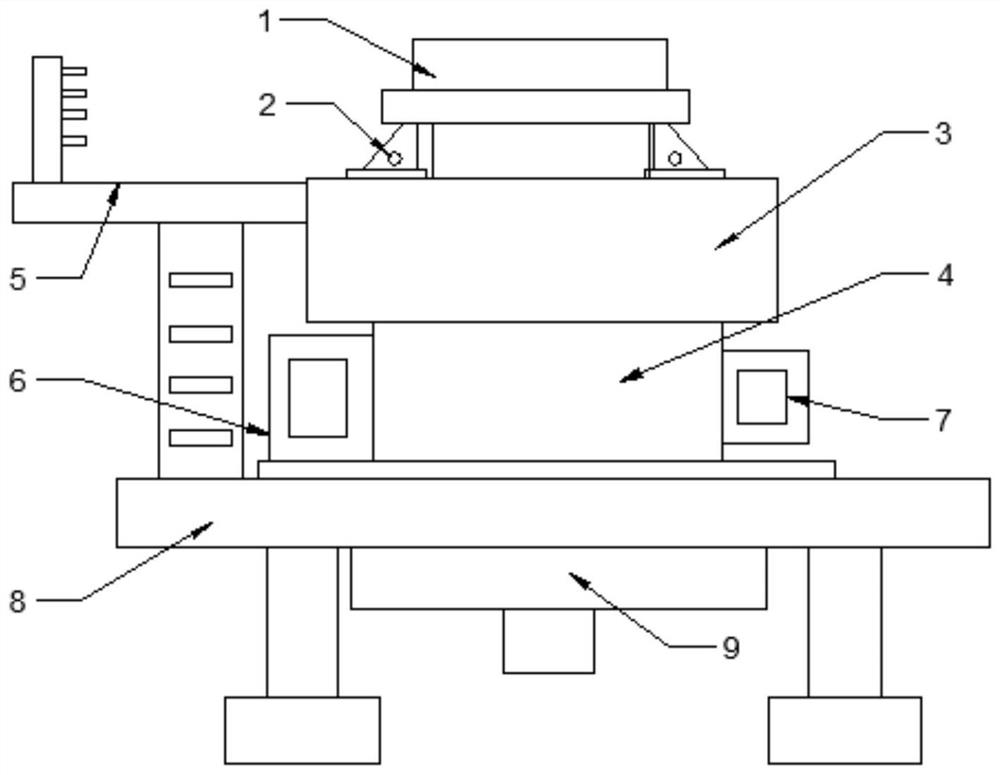

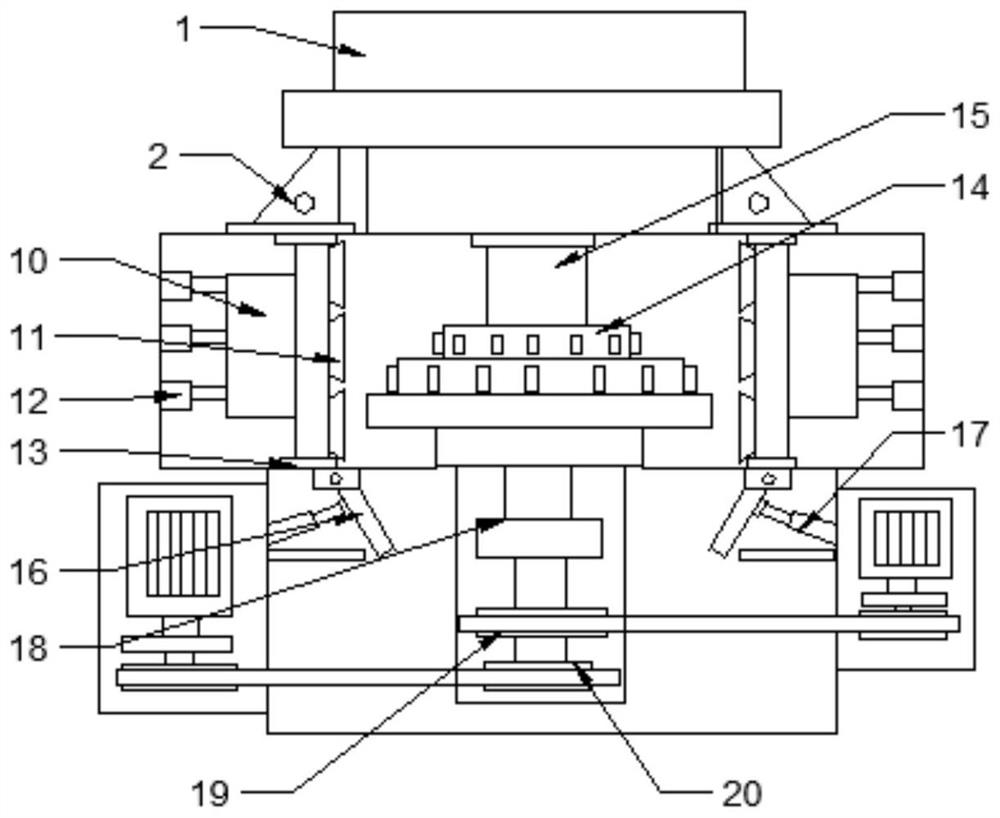

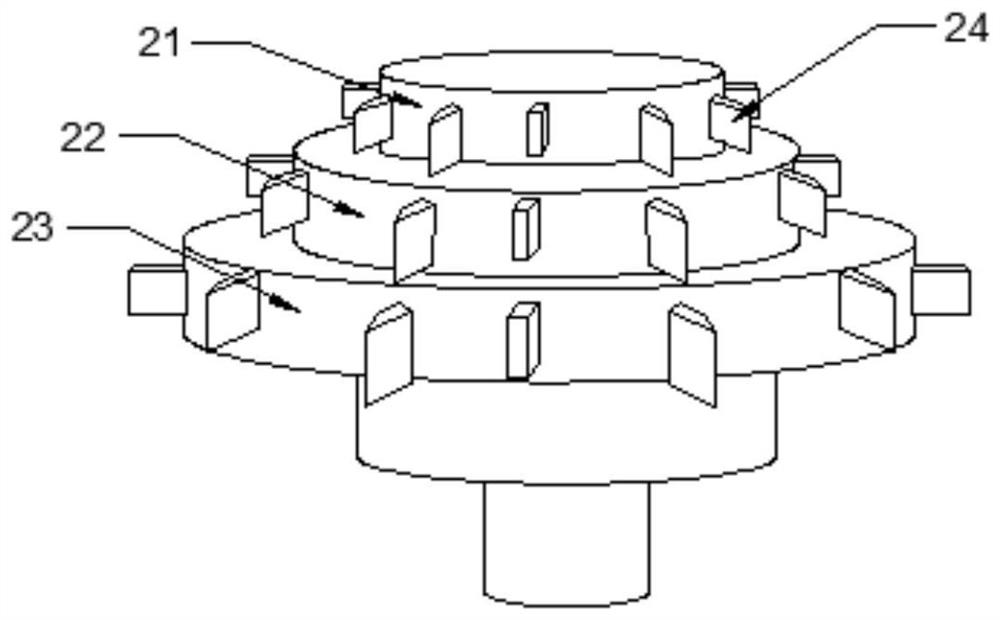

[0021] see Figure 1~3 , in an embodiment of the present invention, a classifiable intelligent sand making machine includes a feed pipe 1; the bottom end of the feed pipe 1 is connected to a crushing box 3; Rib 2; the bottom end of the crushing box 3 communicates with the material guide box 4; the material guide box 4 is fixedly installed on the top of the base 8; the top of the base 8 is provided with a workbench corresponding to the material guide box 4 and the crushing box 3 5; the material guide box 4 is provided with a drive mechanism; the drive mechanism is connected to the classification distribution tray 14; the top of the classification distribution tray 14 is equipped with a positioning shaft 15; the top end of the positioning shaft 15 is fixedly connected by a bearing The inner top of the pulverizing box 3; the inside of the pulverizing box 3 is provided with a side liner mechanism corresponding to the grading and distributing tray 14; The material guide box 4 is p...

Embodiment 2

[0028] see figure 2 , the top and the bottom of the moving plate 10 are equipped with limit sliders; the limit sliders are slidably connected to the guide rail 13; the guide rails 13 are arranged on the crushing box 3; One side of 14 is connected to the inner side of the guide rail 13 through a pressure spring; through the setting of the limit slider, the guide rail 13 and the pressure spring, the stability of the moving plate 10 and the retaining liner 11 can be enhanced when the hydraulic cylinder 12 is adjusted.

[0029] The working principle of the present invention is: through the cooperation of the graded distribution tray 14 and the retaining lining plate 11, the stone is crushed, and through the setting of the No. 1 tray 21, the No. 2 tray 22 and the No. 3 tray 23, different Radius stones are graded and crushed, and the crushing effect is enhanced by setting the impact block 24; by setting the moving plate 10 and the hydraulic cylinder 12, the distance between the blo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com