Manual corrugated pipe bending machine

A corrugated tube and bending machine technology, applied in the direction of metal processing equipment, feeding devices, positioning devices, etc., can solve the problems of increased processing costs, easily damaged corrugated tubes, deformation and breakage of corrugated tubes, etc., to reduce deformation and breakage damage and collapse, avoid bellows wear, and reduce stress concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to enable those skilled in the art to better understand the solutions of the present application, the technical solutions in the embodiments of the present application will be clearly and completely described below in conjunction with the accompanying drawings.

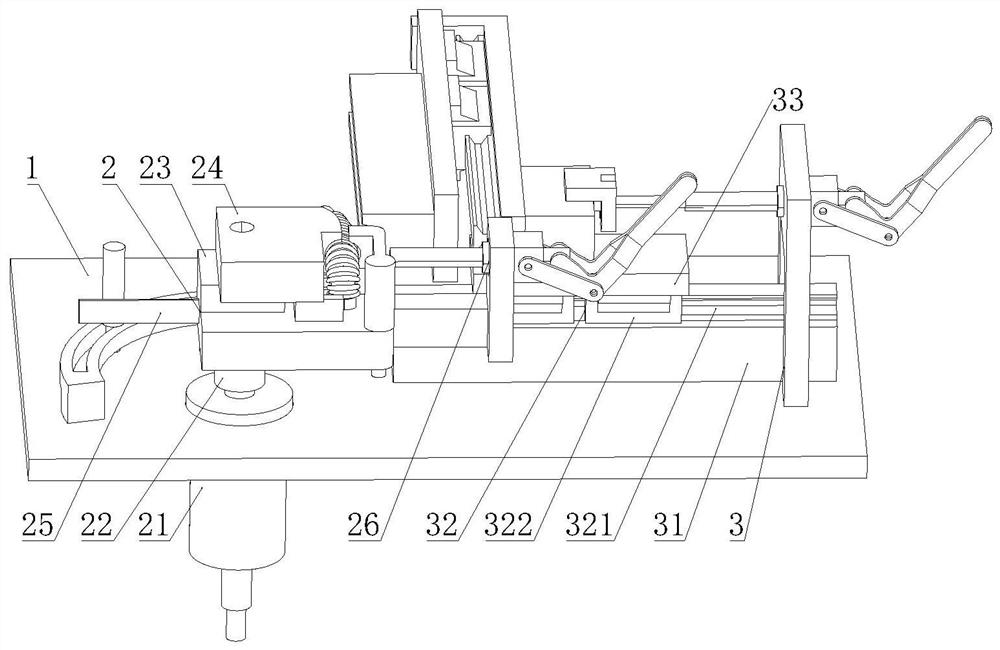

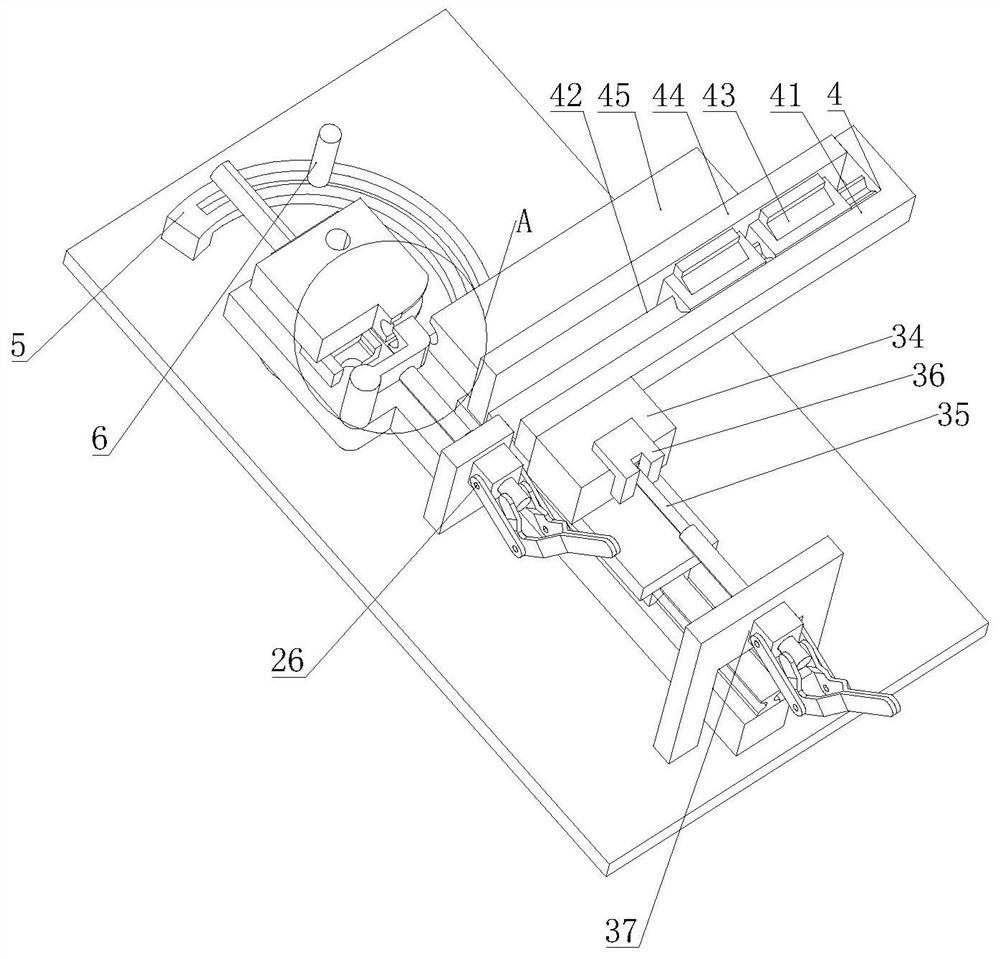

[0037] Such as Figure 1-Figure 4 As shown, the present invention includes a workbench 1, on which a wheel mold installation assembly 2 and a guide mold swing assembly 4 are arranged, so as to complete the fixing and bending of the bellows according to requirements.

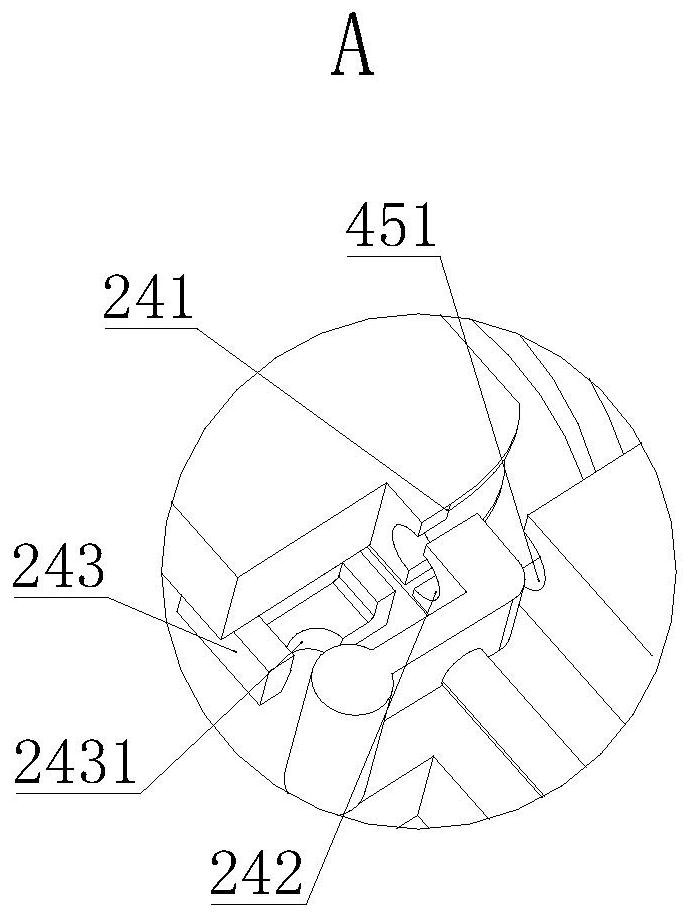

[0038] Wheel mold installation assembly 2 comprises wheel mold main shaft 21, and wheel mold main shaft 21 is provided with boss, to ensure that wheel mold main shaft 21 is firmly connected with workbench 1, and the upper surface of boss fits workbench 1. Wheel mold main shaft 21 is connected with wheel mold 23 through workbench 1, so that drive wheel mold 23 rotates around the vertical line perpendicular to the horizontal plane of wheel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com