Multi-stage load reduction device

A technology for load reduction and installation of planes, which is applied in the field of gyro-type multi-stage load reduction devices, can solve the problems that the load reduction head cap cannot meet the load reduction requirements, and the structure of the aircraft body is scratched, etc., to achieve low cost, easy construction, and avoid The effect of a bullet that is too long

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

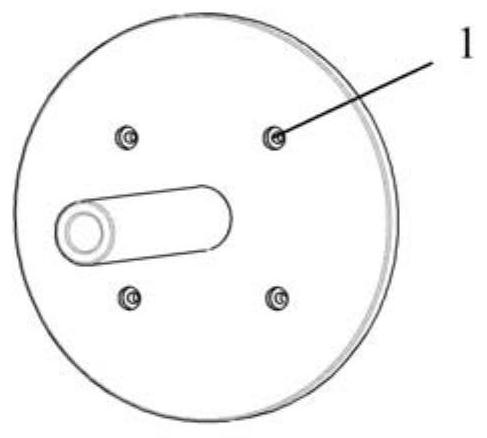

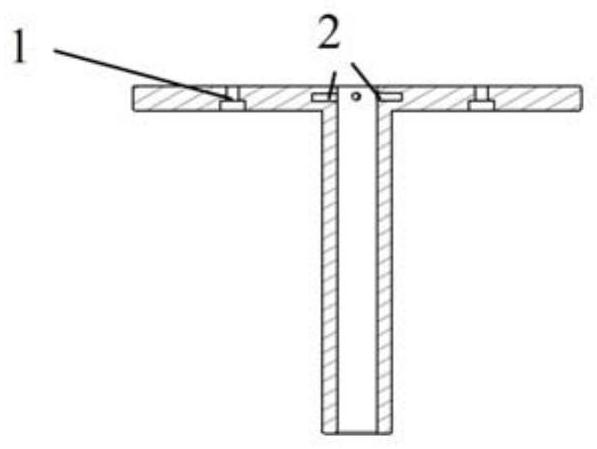

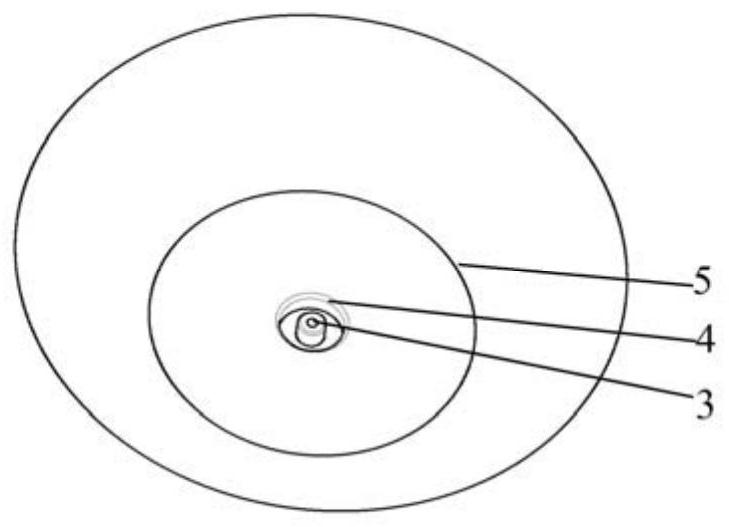

[0031] The multi-stage load reduction device of the present invention is mainly composed of three parts, namely: a gyro-type cavitator, a round table breakable part (foam), and a telescopic connecting pipe.

[0032] The combined gyro-type high-speed water-entry multi-stage load-reduction device of the present invention is installed on the head of the vehicle. The chassis of the load-reduction device is fixedly connected to the head of the vehicle through fastening screws. When the vehicle enters the water, the load-reduction device enters the water first. The gyro-type cavitator first forms water-entry cavitation to reduce the surface of the impact load; under the action of the water-entry impact load, the gyro-type cavitator advances inward along the track of the retractable connector, converting the impact load into gyro-type cavitation At...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com