Tension leg platform-wind turbine double-body modular floating integrated system and use method thereof

A technology of tension leg platform and integrated system, which is applied in the direction of wind turbine, wind motor combination, installation/support configuration of wind turbine, etc. It can solve problems such as collision damage, achieve improved force characteristics, save installation and removal costs, and reduce The effect of construction precision requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

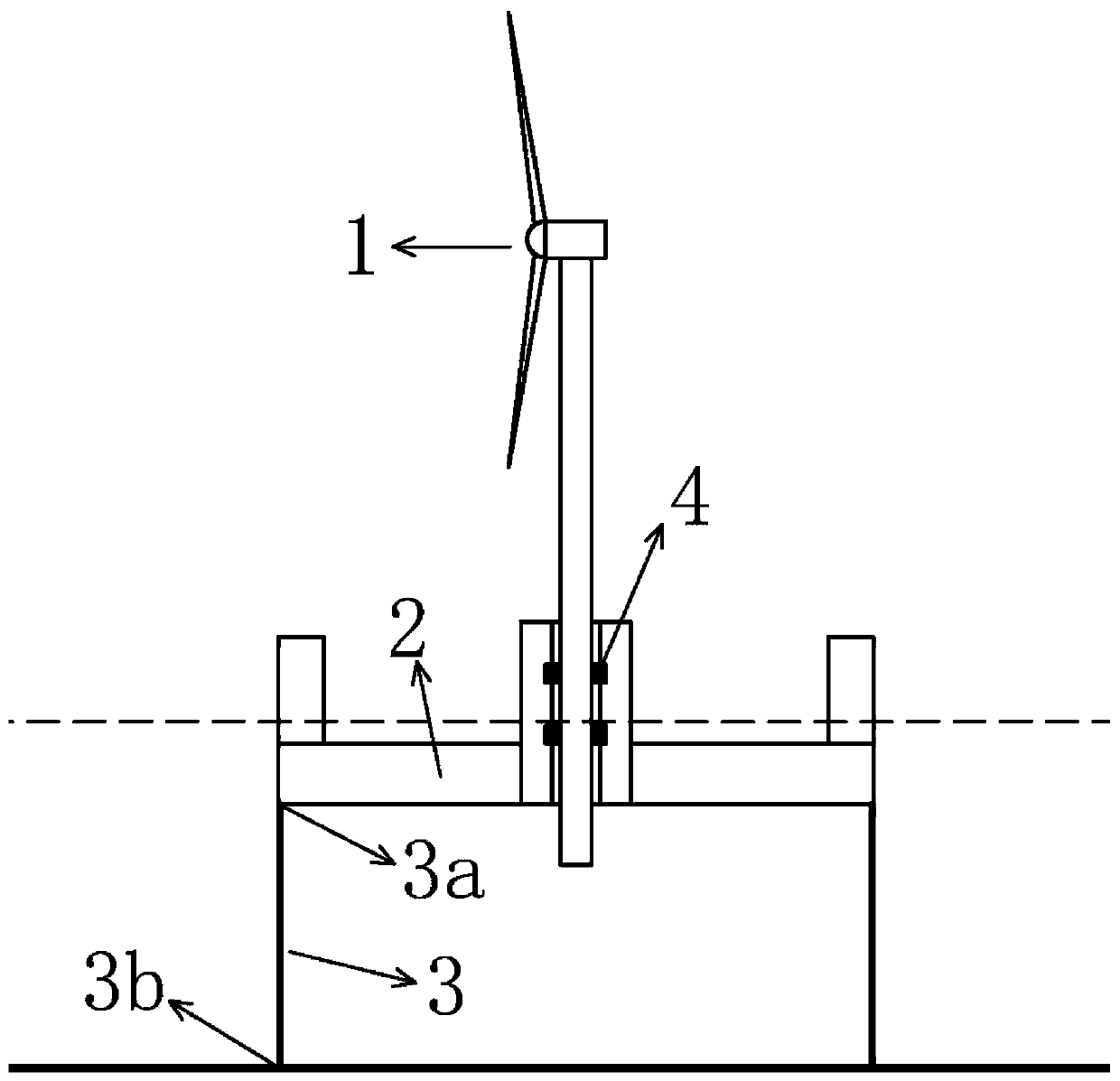

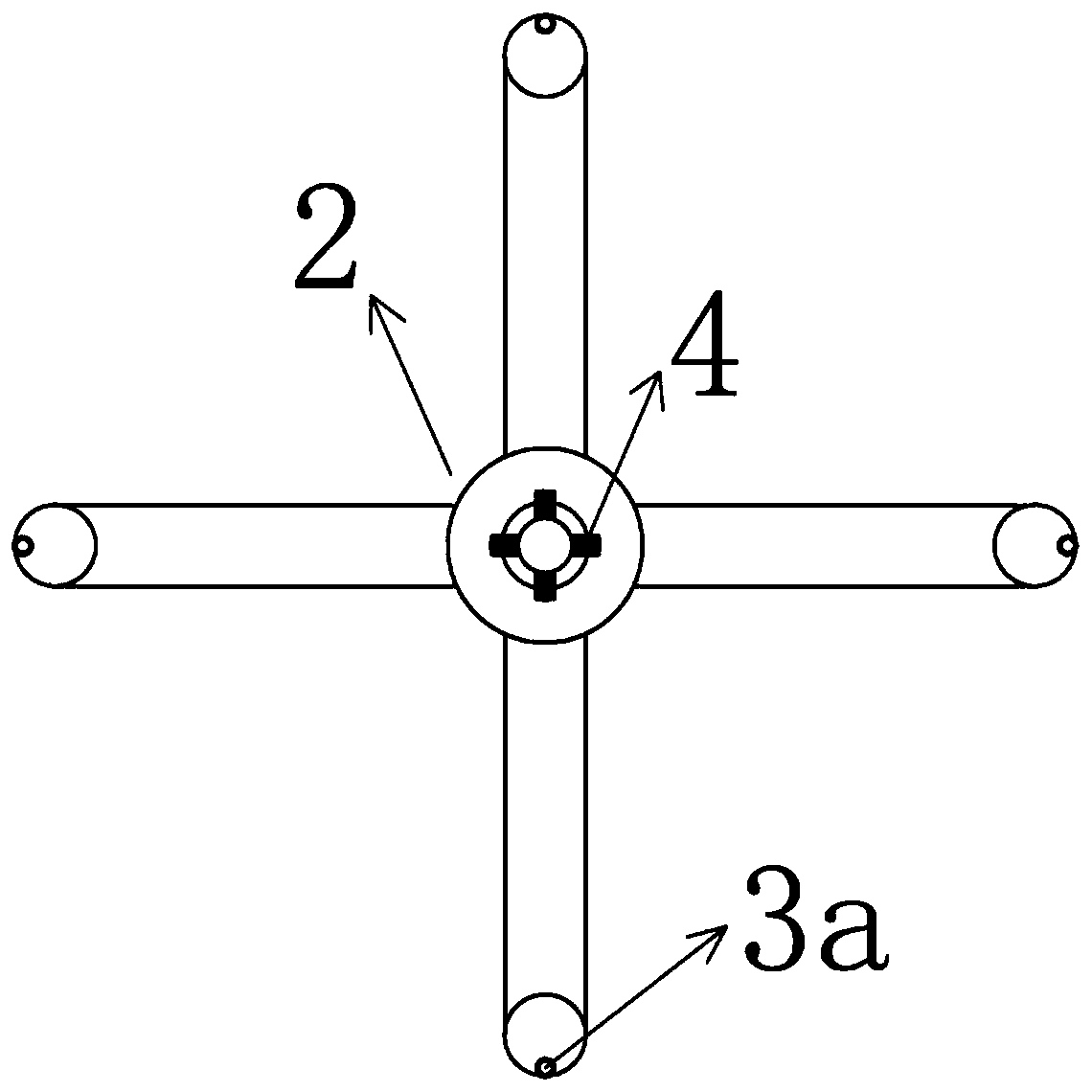

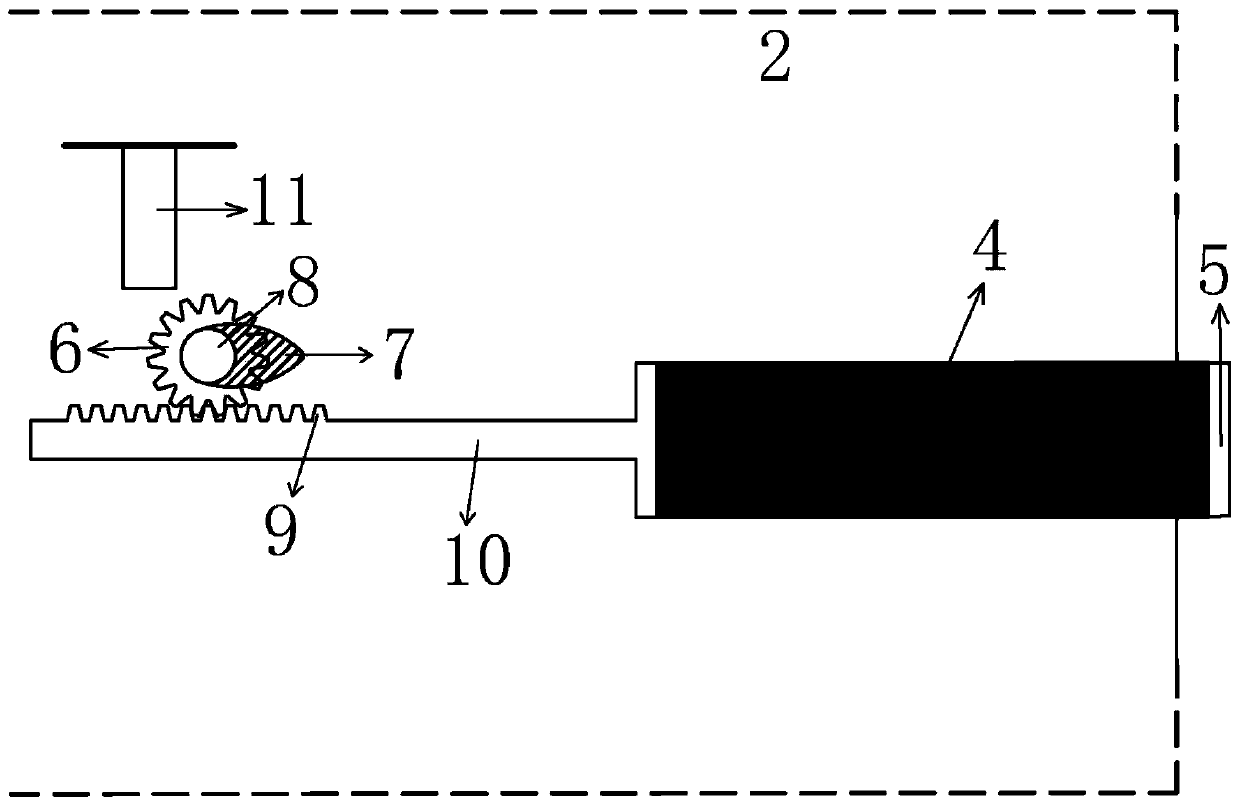

[0027] The tension leg platform-wind turbine two-body modular floating integrated system includes a wind turbine module 1, a tension leg platform module 2, a tension leg system 3, and a platform-wind turbine tower clamping device.

[0028]The self-weight and buoyancy of the wind turbine module 1 are self-balanced; the tension leg platform module 2 can achieve self-balance through its own structural gravity plus tension leg pretension and buoyancy, and a wind turbine sleeve is arranged in its center, and its inner diameter is larger than The outer diameter of the wind turbine module 1 is 1m larger, and the bottom of the wind turbine module 1 can enter the sea through the sleeve; the tension leg system 3 includes four symmetrically distributed tension legs, the upper end of which is connected to the four end angles of the tension leg platform modu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com