Transfer equipment for cold chain transporting

A technology of cold chain transportation and equipment, applied in the field of transfer equipment for cold chain transportation, can solve the problems of internal transportation products being susceptible to external shocks, low work efficiency, increased loss costs, etc., so as to ensure the quality of logistics transportation and reduce labor. , the effect of reducing the impact force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

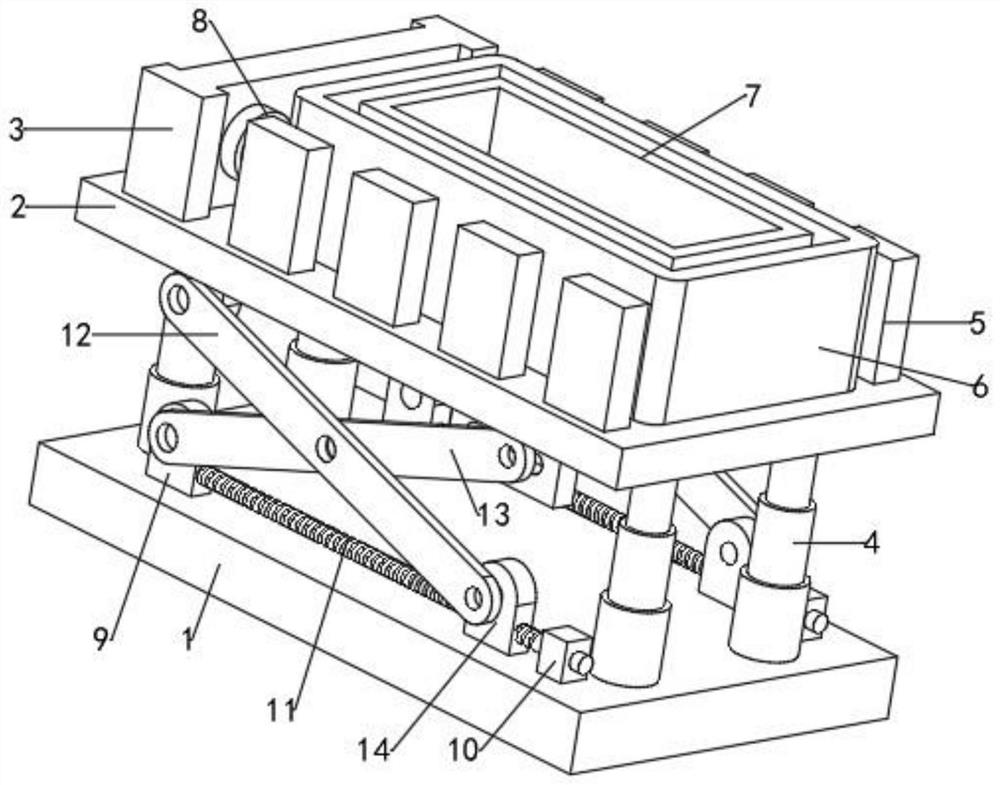

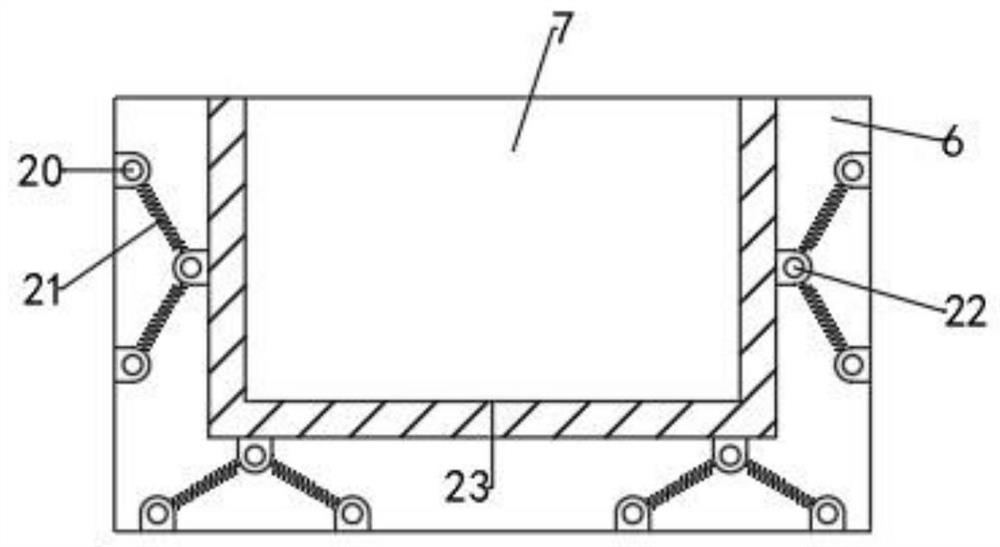

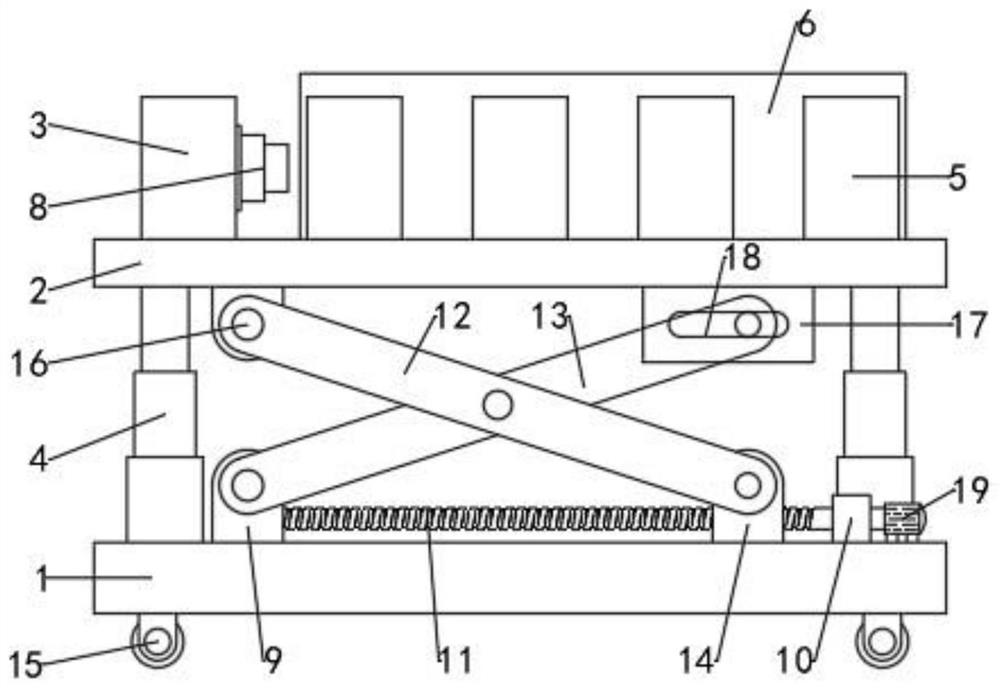

[0020] see Figure 1-4 , a transshipment device for cold chain transportation, comprising a sub-cargo box 7, the periphery of the sub-cargo box 7 is equipped with a mother cargo box 6, and a plurality of connecting seats 22 are evenly distributed on the outside of the sub-cargo box 7, and the mother cargo box The inner side of 6 is evenly provided with a plurality of assembly seats 20, and the number of assembly seats 20 is twice that of the connection seats 22, and each of the connection seats 22 is rigidly connected with two assembly seats 20 by a shock-absorbing spring 21; The inner side of the box 7 is provided with a heat insulation layer 23, the mother cargo box 6 is placed on the seat 2, and the seat 2 is provided with a clamping mechanism and a push mechanism, and the lower end of the seat 2 is connected with a lifting mechanism; the push mechanism includes Base plate 3, base plate 3 is fixed on one side of the upper end surface of placement seat 2, and the cross secti...

Embodiment 2

[0029] In order to facilitate the movement and placement of the transfer equipment in actual use, this embodiment is improved on the basis of Embodiment 1. The improvement is: the lower end of the base 1 is connected with rollers 15, and the number of rollers 15 is four And it is laid out at the four corners of a rectangle.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com