Safety protection type elevator

A safety protection and safety protection technology, applied in elevators, transportation and packaging, etc., can solve the problems of reduced braking capacity, slippage, difficult operation, etc., and achieves the effect of fast operation speed, reliable monitoring results, and easy rapid detection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

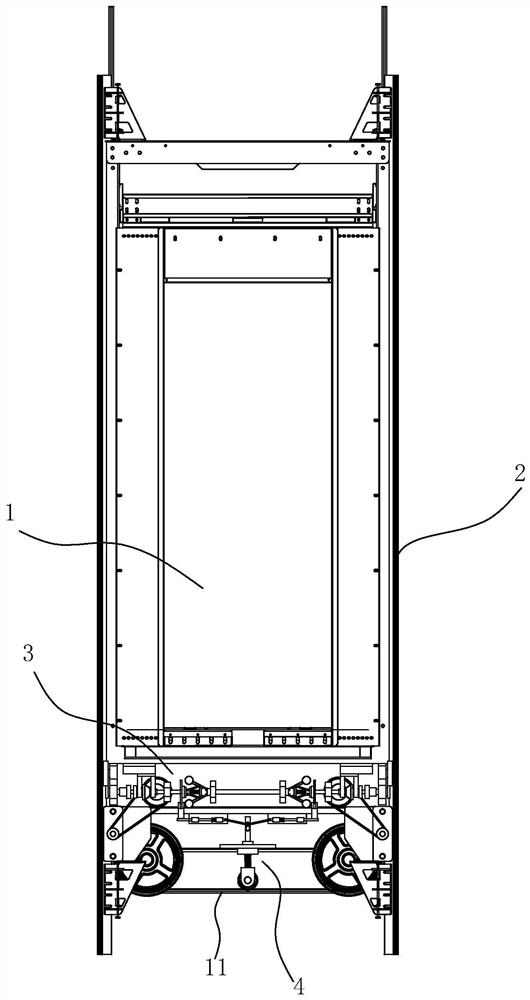

[0028] The safety-protected elevator of this embodiment includes a traction system, a guide system, a door system, a car, a weight balance system, an electric drive system, an electrical control system, and a safety protection system, wherein the safety protection system includes a speed-limiting braking device 3, Broken rope monitoring device 4, slipping monitoring device 5.

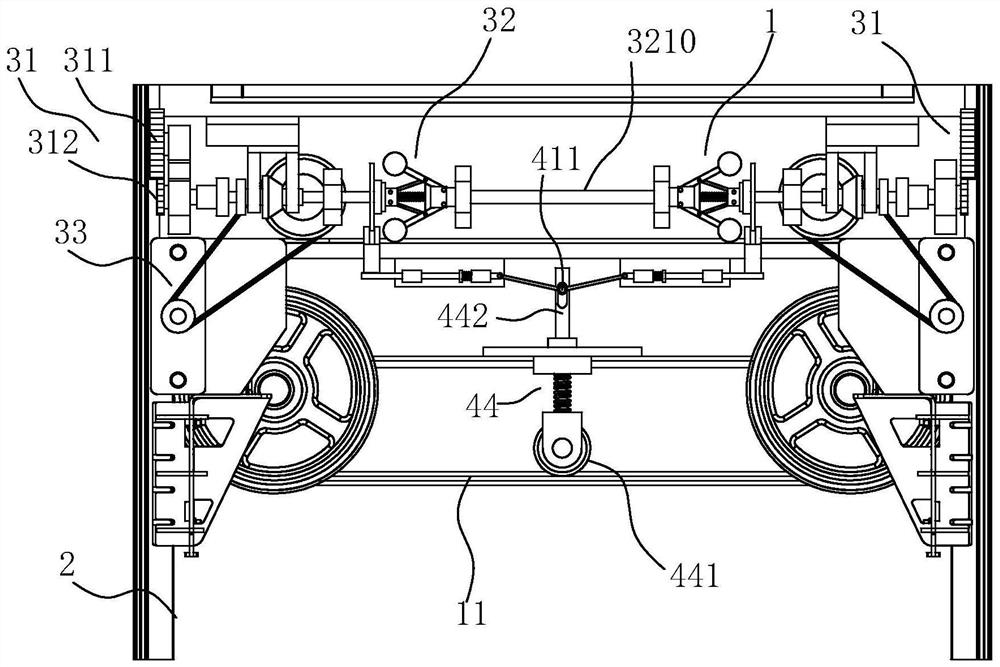

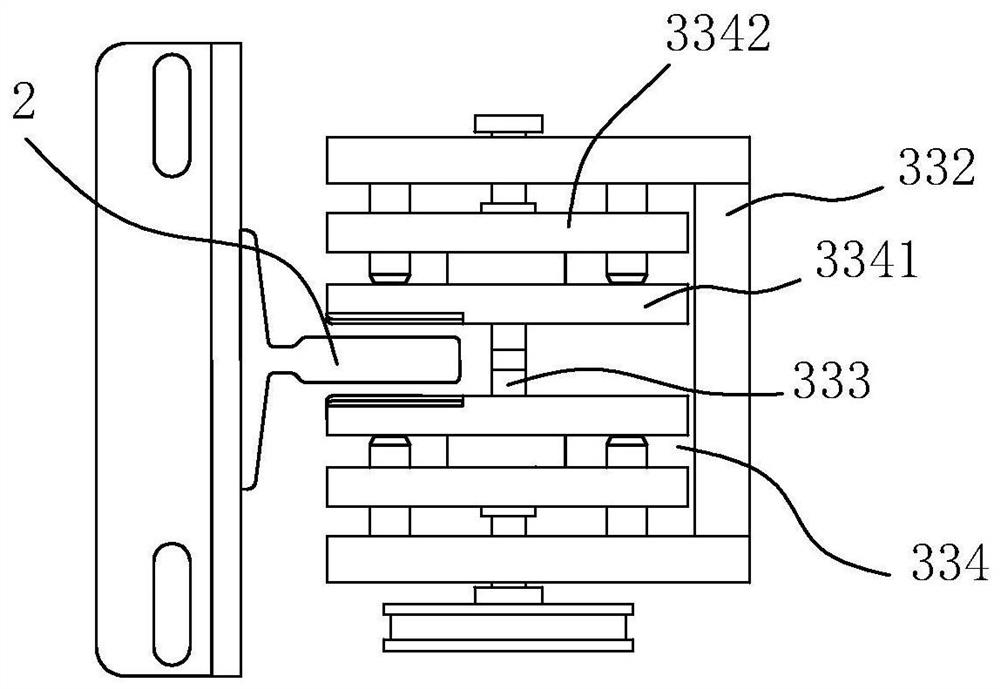

[0029] see Figure 1-Figure 6 The car 1 is provided with two speed-limiting braking devices 3, and the two speed-limiting braking devices 3 are connected through a central shaft 3210. The speed-limiting braking device 3 includes a friction drive module 31, a speed-limiting trigger module 32, a braking module 33 and The function of the reset ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com