Construction method of large stone railing on bridge floor

A construction method and railing technology, which are applied in chemical instruments and methods, processing of building materials, mixing plants, etc., can solve problems such as affecting the quality of stone railing installation, affecting the service life of stone railings, and inconvenient for paving of seat slurry, etc. To achieve the effect of convenient blocking, convenient and safe, easy to fix and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

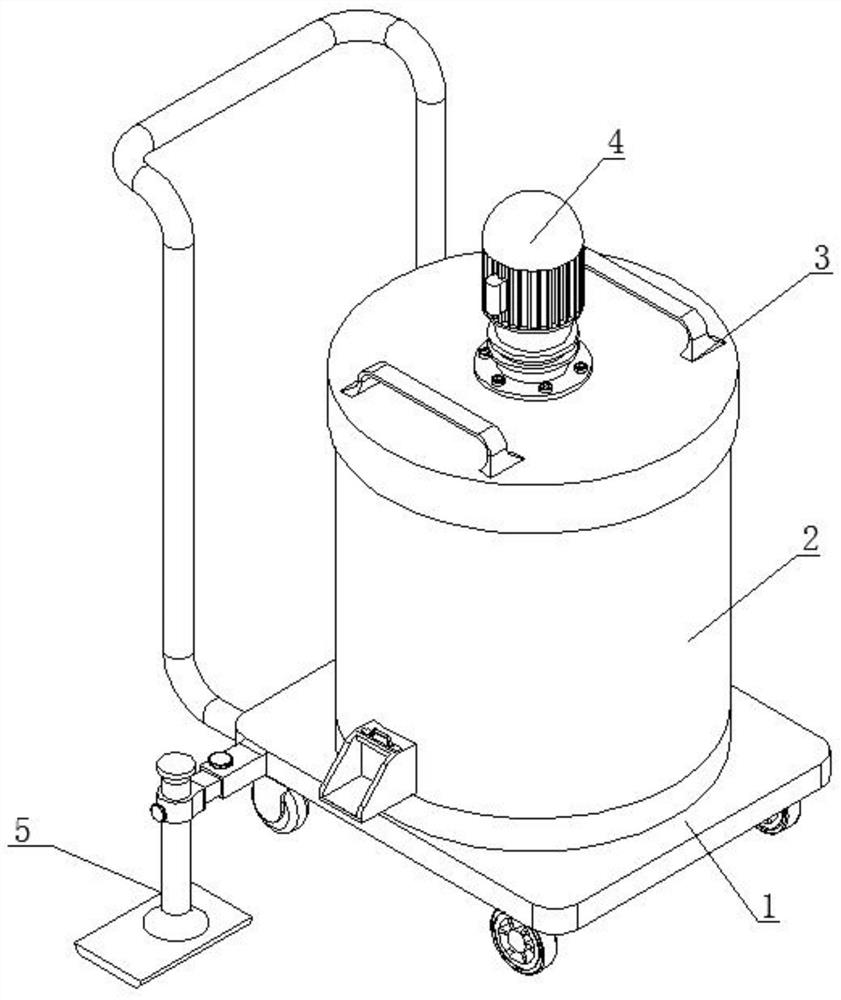

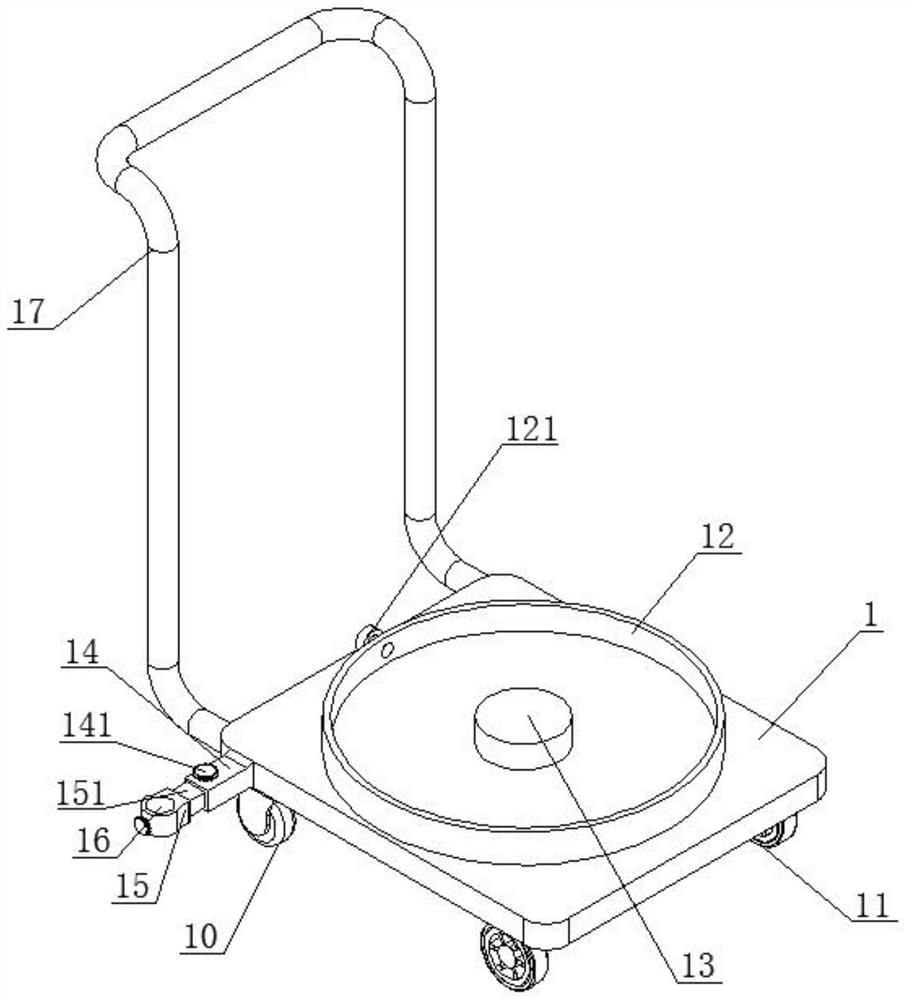

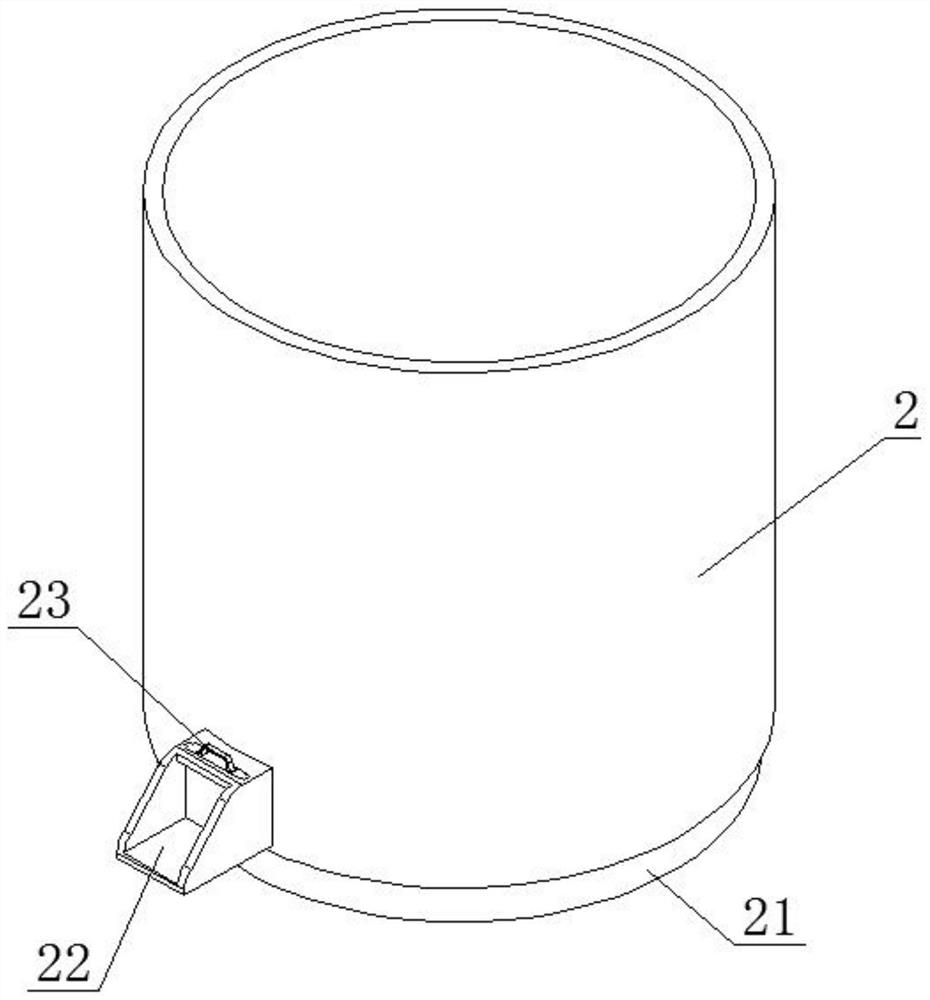

[0052] Example: refer to figure 1 , Figure 6 and Figure 8 Shown: a construction method for large stone railings on the bridge deck, the specific steps of the method are as follows:

[0053] S1: Construction preparation

[0054] According to the design requirements, the construction plan shall be formulated in combination with the site conditions, and the arrangement diagram of the pull plates, columns, drums and other components of the stone railings shall be drawn according to the design drawings before the installation of the stone railings;

[0055] S2: Positioning for setting out

[0056] The shape, size and elevation of the bridge deck are scanned by a pay-off robot scanner. The 3D CAD drawings obtained on the scanner are segmented according to the shape of the bridge deck with each bending position on the drawing, and the axis is set and integrated. It is a traditional two-dimensional CAD drawing, and then set the points of each stone railing column on the drawing,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com