Lower lifting point lifting device and lower lifting point integrated integral lifting method

A technology of hanging point and hydraulic lifter, which is applied in transportation and packaging, load hanging components, construction, etc. It can solve the problems of difficult deformation control, difficult installation and high construction cost, and reduce high-altitude dismantling work , Simplify the form of lifting points and reduce the difficulty of construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

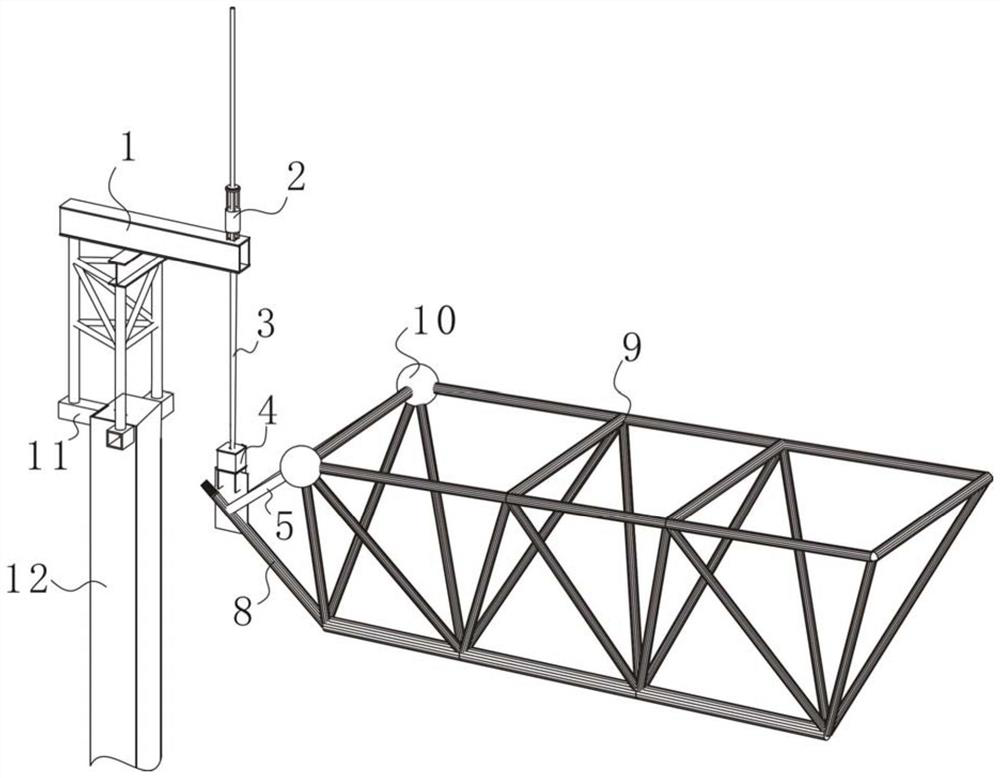

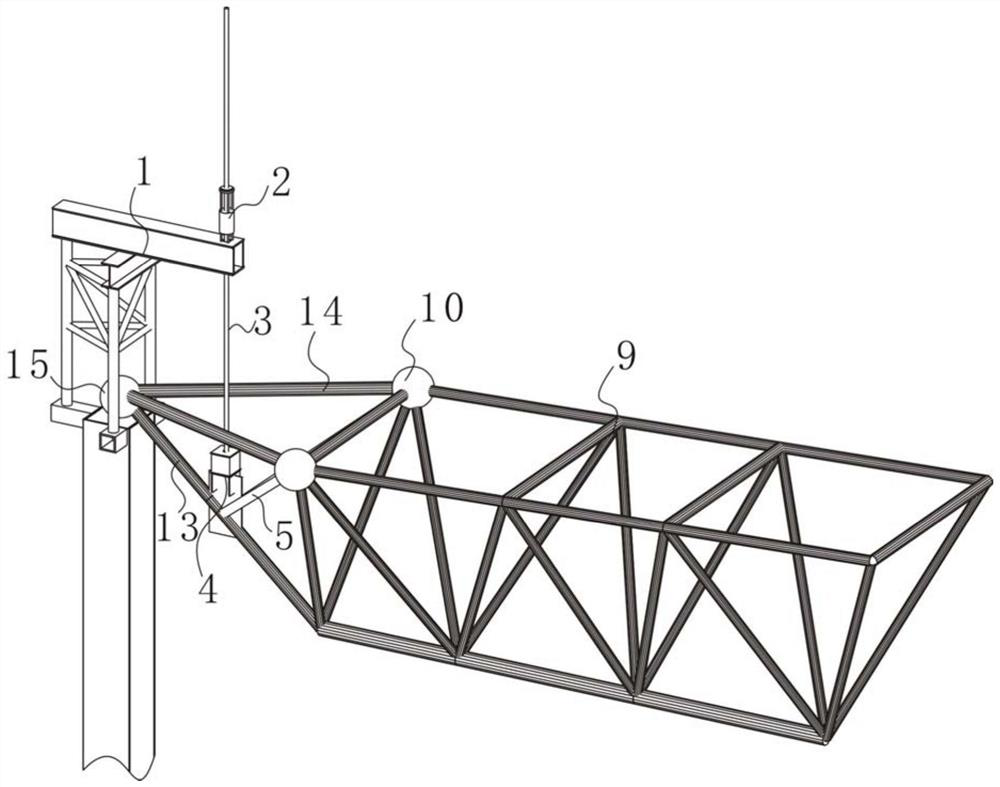

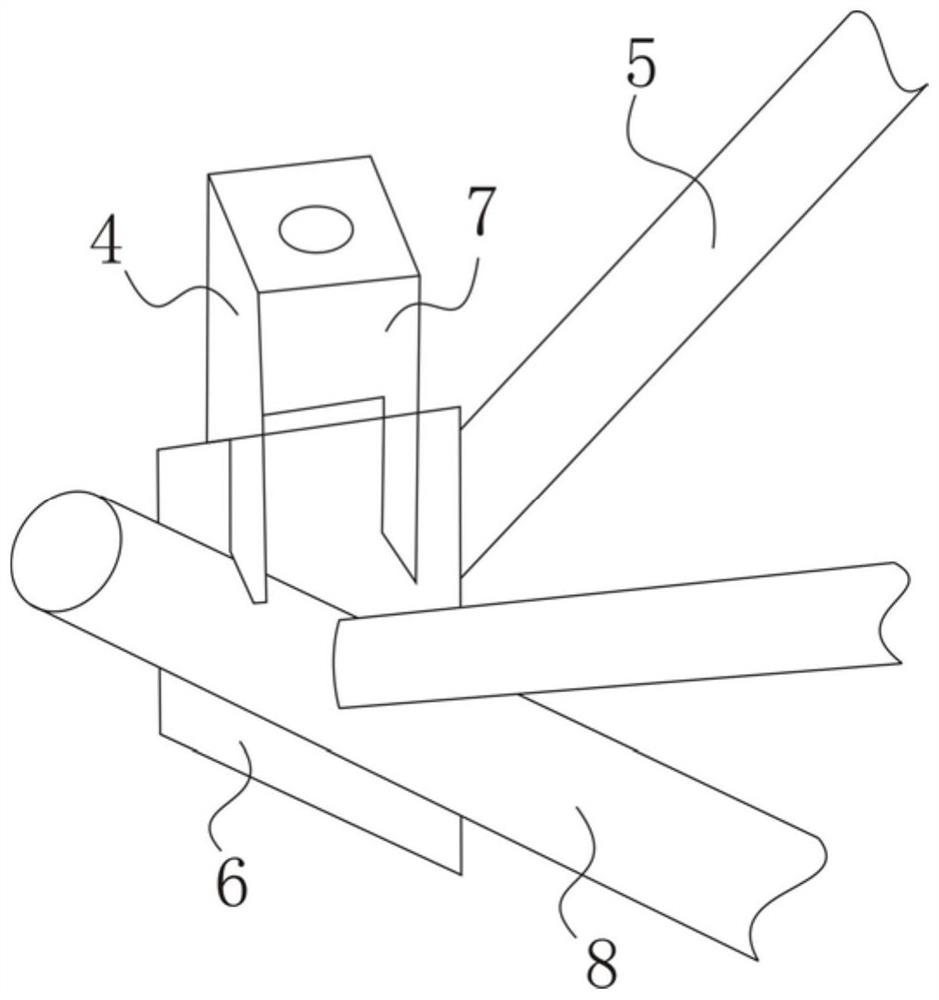

[0026] As shown in the figure, the present invention provides a hoisting device for the lifting point, which is distributed symmetrically around the circumference of the truss 9. The hoisting device includes a lifting bracket 1, a hydraulic lifter 2, a steel strand 3, a hoisting Plate 4 and two sets of connecting rods 5, wherein the lifting bracket 1 is fixed on the corbel 11 on the top of the column 12, the hydraulic lifter 2 is fixed on the lifting bracket 1, the hydraulic lifter 2 pulls the steel strand 3 upward, and the hanging plate 4 It includes a detachably connected flashboard 6 and a hanger 7, the flashboard 6 is vertically inserted into the lower chord 8 outside the truss 9, and the flashboard 6 is fixedly conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com