Field foundation ditch rail with dust-proof function

A technology for construction sites and foundation pits, applied to fences, smoke and dust removal, cleaning methods and appliances, etc., can solve problems such as single function and hazards, and achieve the effect of fast flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

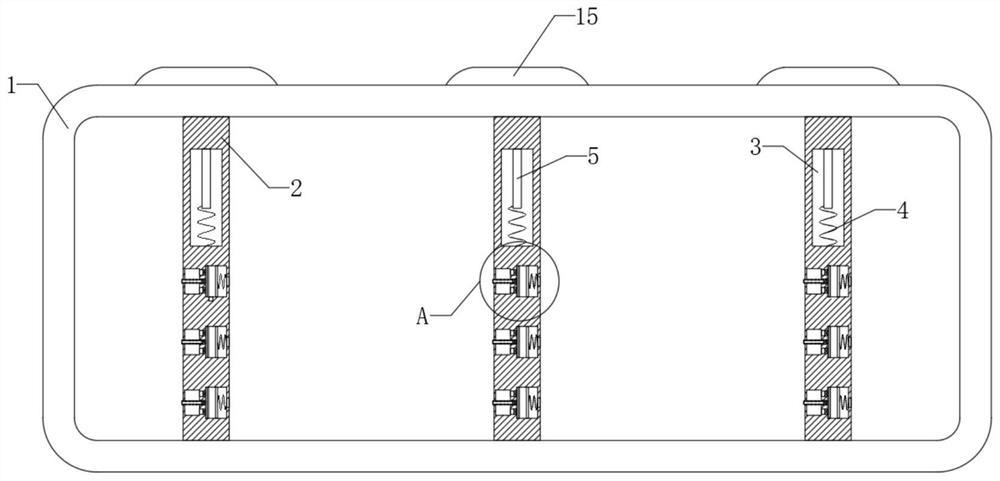

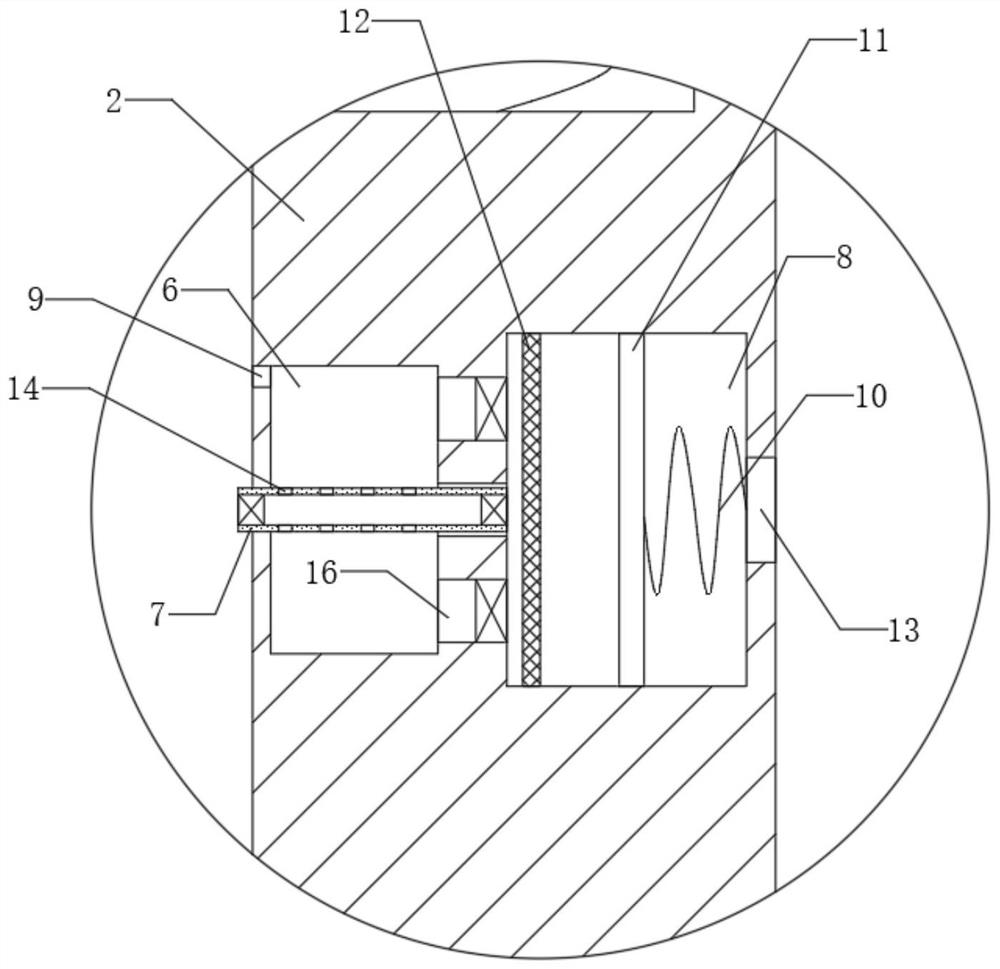

[0021] refer to Figure 1-2 , a construction site foundation pit fence with dust removal function, comprising a frame body 1, a plurality of vertical rods 2 are welded in the frame body 1, a strip groove 3 is opened on the side wall of the vertical rod 2, and the inner top of the strip groove 3 is fixed A bar magnet 5 is connected, and a helical coil 4 is fixedly connected to the inner bottom of the bar slot 3 .

[0022] It is worth mentioning that a plurality of warning lights 15 coupled to both ends of the helical coil 4 are installed on the upper end of the frame body 1, and a bright resistor is connected in series in the circuit formed by the helical coil 4 and the warning lights 15, so that it can be used during construction at night. , so that the warning lights 15 are continuously flashed to provide a warning effect to passing vehicles, so as to prevent drivers from colliding with the fence of the foundation pit when the lights are dim at night because they cannot see t...

Embodiment 2

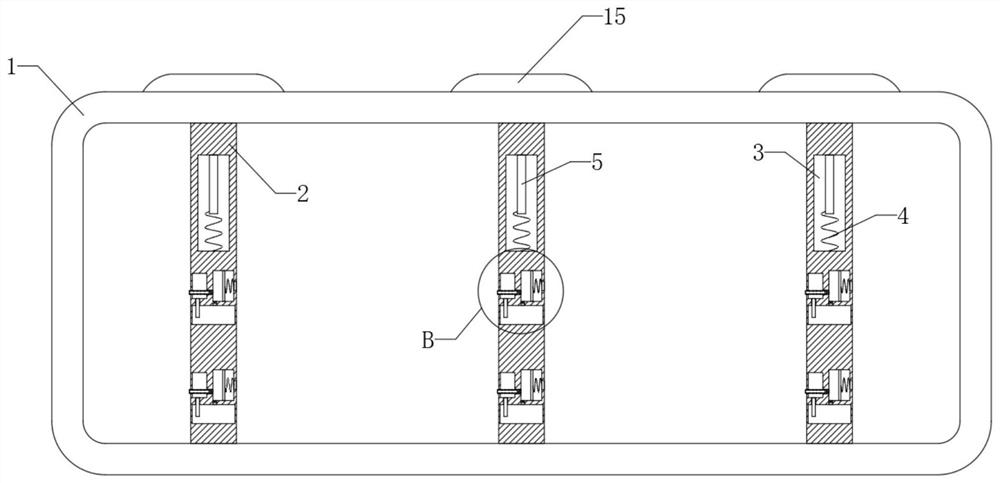

[0031] refer to Figure 3-4 , which is different from Example 1. The side wall of the vertical rod 2 is provided with a settling chamber 17, and the settling chamber 17 and the pumping chamber 8 communicate with each other through the second one-way passage 19, and the inner bottom of the liquid storage chamber 6 is fixedly connected with a conduit 18 communicating with the inside thereof, and the conduit 18 extends into the precipitation chamber 17. In this embodiment, there is no need to set a filter screen, let alone to clean the filter screen frequently. It should be noted that there is an opening on the inner wall of the sedimentation chamber 17, and a valve is installed at the opening, the valve can be opened regularly to clean the dust accumulated at the bottom of the sedimentation chamber 17, which is convenient for cleaning, and the cleaning interval is long and the number of cleanings is small .

[0032] In this embodiment, when the piston 11 moves left and right,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com