Step-by-step adjustable borehole finisher

A dresser and wellbore technology, applied in wellbore/well components, earth-moving drilling, etc., can solve the problems of large diameter expansion, irreparable, stuck drill, etc., and achieves small diameter expansion error, novel structure design, Easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

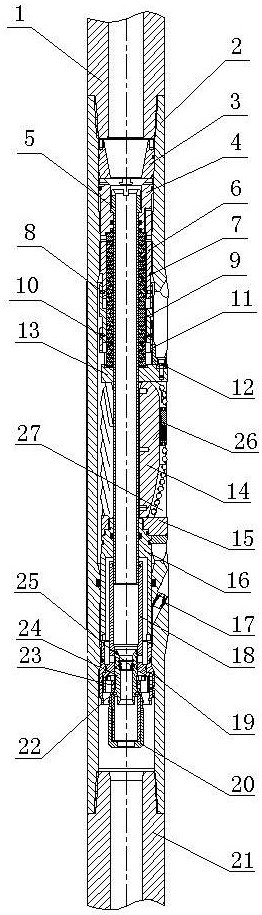

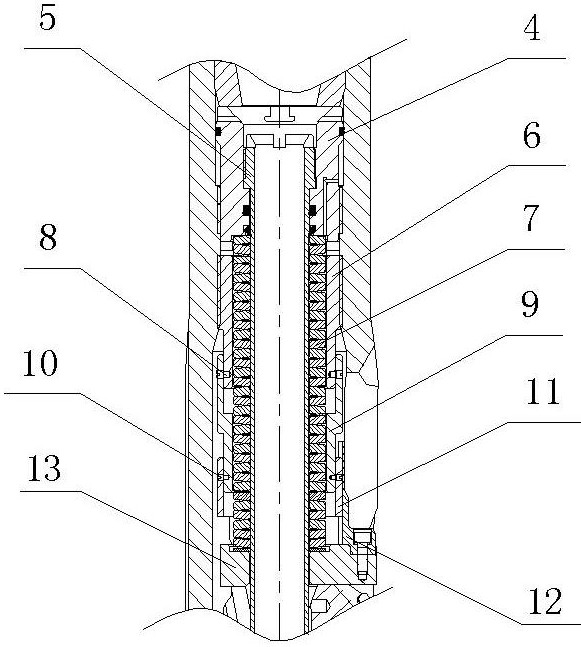

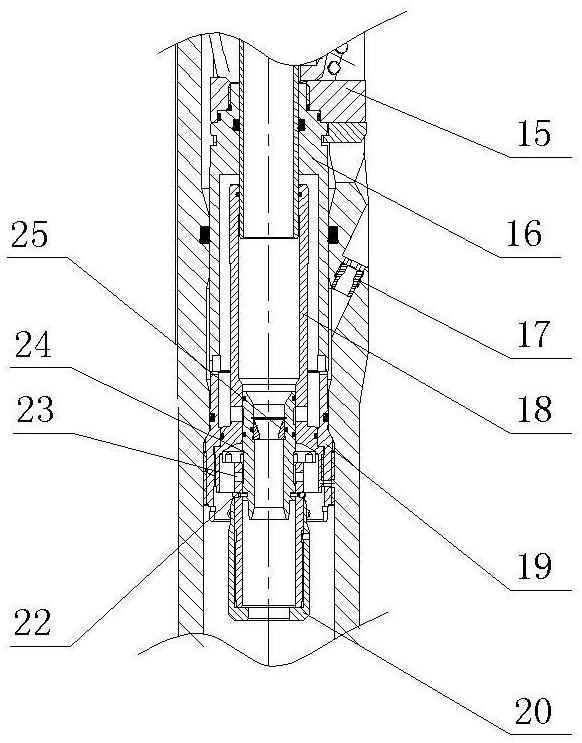

[0014] A step-by-step adjustable wellbore trimmer of the present invention is composed of an upper joint 1, a housing 2 and a lower joint 21. The upper joint 1, the housing 2 and the lower joint 21 are sequentially threaded, and the housing 2 Built-in mandrel 5, the outer periphery of mandrel 5 is installed with loam cake 4, outer diameter adjustment assembly, disc spring rear cover 12, cutter body assembly and piston assembly sequentially from top to bottom. A ball guide 3 is installed on the front end of the mandrel 5 in the housing 2, and the ball guide 3 is connected with the mandrel 5 with a screw thread, and is funnel-shaped.

[0015] The outer diameter adjustment assembly is that a disc spring 7 is set on the upper end of the mandrel 5, and the outer circumference of the disc spring 7 is successively set with a third-stage disc spring barrel 6, a second-stage disc spring barrel 9, and a first-stage disc spring. Tube 11, three-stage disc spring tube 6 and secondary disc ...

Embodiment 2

[0019] A step-by-step adjustable wellbore trimmer of the present invention, the upper joint 1, the housing 2, and the lower joint 21 are all cylindrical and threaded, meeting the requirements for the transmission strength of the drilling tool assembly, and the housing 2 is equipped with water holes 17 , for the mud to pass through the cooling cutter block 14 and carry cuttings. The ball guide 3 is connected with the mandrel 5 threaded, funnel-shaped, the upper end diameter is greater than the inner diameter of the upper joint, and the lower end is consistent with the inner diameter of the mandrel 5, which is convenient for the ball to pass through and guide the ball to enter the mandrel smoothly. Mandrel 5 is threaded with disc spring 7 and outer diameter adjustment assembly, and disc spring 7 and outer diameter adjustment assembly is threaded with mandrel 5. Its position on mandrel 5 can be adjusted during assembly, depending on the position After the cutter block 14 protrude...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com