System and method for efficiently purifying volatile organic compounds (VOCs) generated in roast duck making process

A production process and roast duck technology, applied in chemical instruments and methods, separation methods, combustion methods, etc., can solve the problems of large gas volume and high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

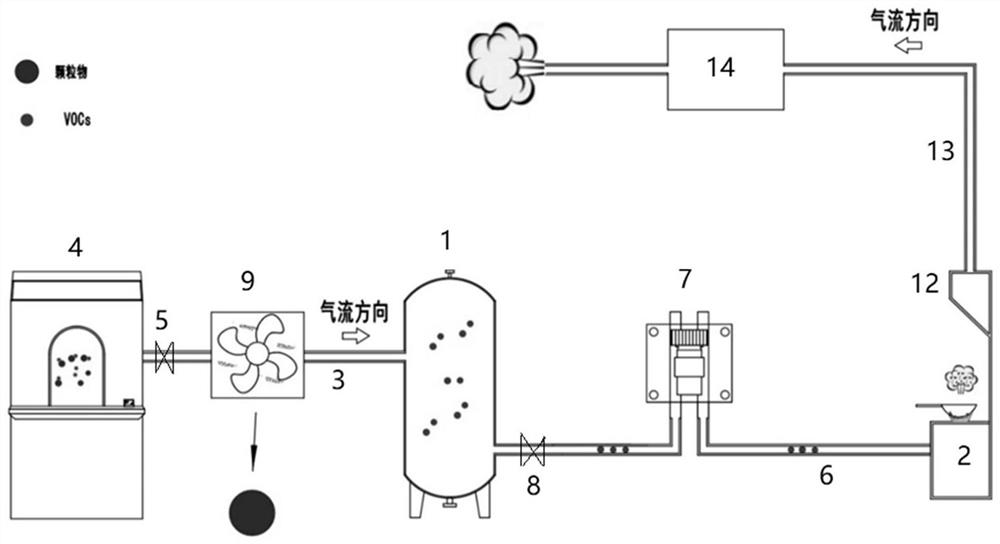

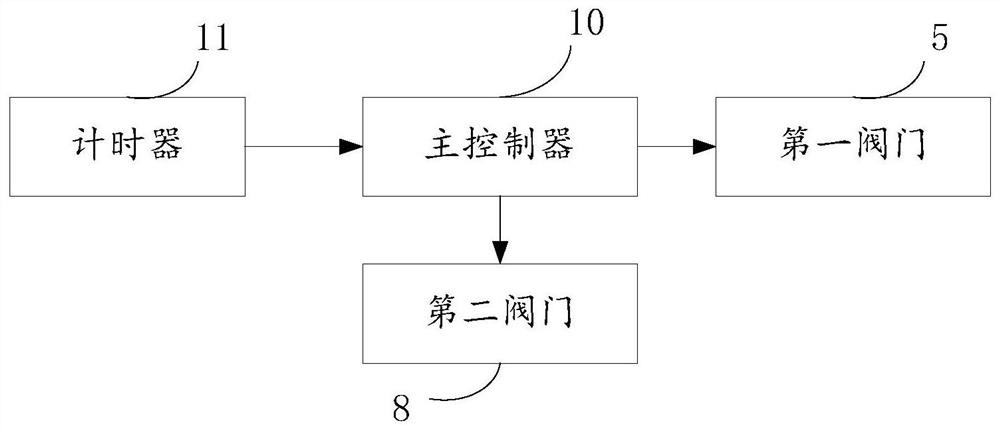

[0031] Such as figure 1 As shown, the embodiment of the present invention provides a system for efficiently purifying VOCs produced in the roast duck production process, including: a negative pressure gas storage device 1 and a VOCs thermal combustion device 2, and the air inlet of the negative pressure gas storage device 1 The first pipeline 3 is connected to the furnace cavity of the airtight roast duck oven 4, and the first valve 5 is arranged on the first pipeline 3; The combustion-supporting gas inlet of the combustion device 2 is connected, and the second pipe 6 is provided with a flue gas conveying device 7 and a second valve 8 .

[0032] In the above system, the negative pressure gas storage device can be a vacuum tank, the flue gas delivery device can be a vacuum pump, and the VOCs thermal combustion device refers to a device that uses a thermal combustion method to process VOCs. The thermal combustion method is generally used to deal with the low concentration of VO...

Embodiment 2

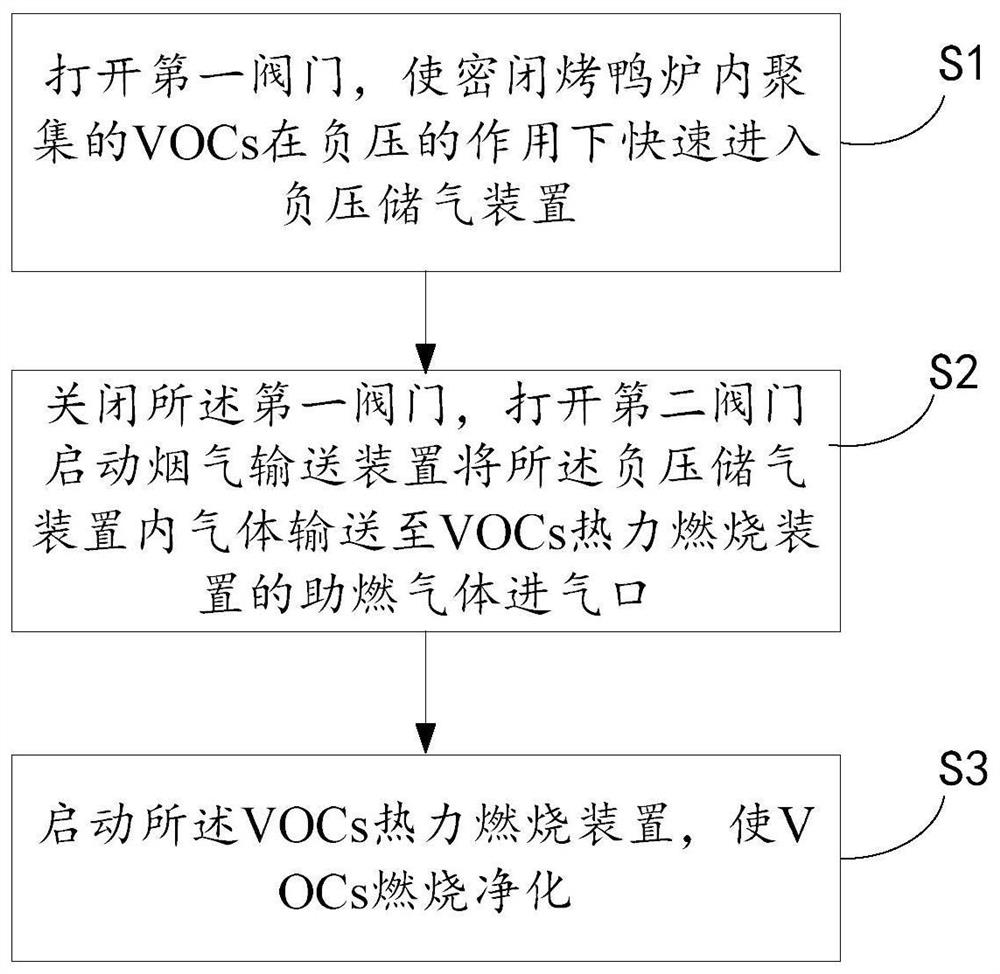

[0058] Such as image 3 As shown, the embodiment of the present invention provides a method for efficiently purifying VOCs produced in the roast duck production process using the system as described in Embodiment 1, including:

[0059] S1, open the first valve, so that the VOCs accumulated in the airtight roast duck oven quickly enter the negative pressure gas storage device under the action of negative pressure;

[0060] S2, closing the first valve, opening the second valve, starting the flue gas delivery device to deliver the gas in the negative pressure gas storage device to the combustion-supporting gas inlet of the VOCs thermal combustion device;

[0061] S3, start the VOCs thermal combustion device to burn and purify the VOCs.

[0062] Further, the opening of the first valve includes:

[0063] The main controller detects whether the timing of the timer is over, and if so, generates a first control command and sends it to the first valve, and the first control command i...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap