Glass plate and glass paper clamping device and method

A technology of glass plate and cellophane, which is applied in the direction of transportation and packaging, packaging, and the type of packaged items. It can solve the problems of insufficient packaging area while placing the A-frame of the paper cutter and insufficient space in the packaging area, and achieves simple structure and reduced occupation. The effect of floor area and increased safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

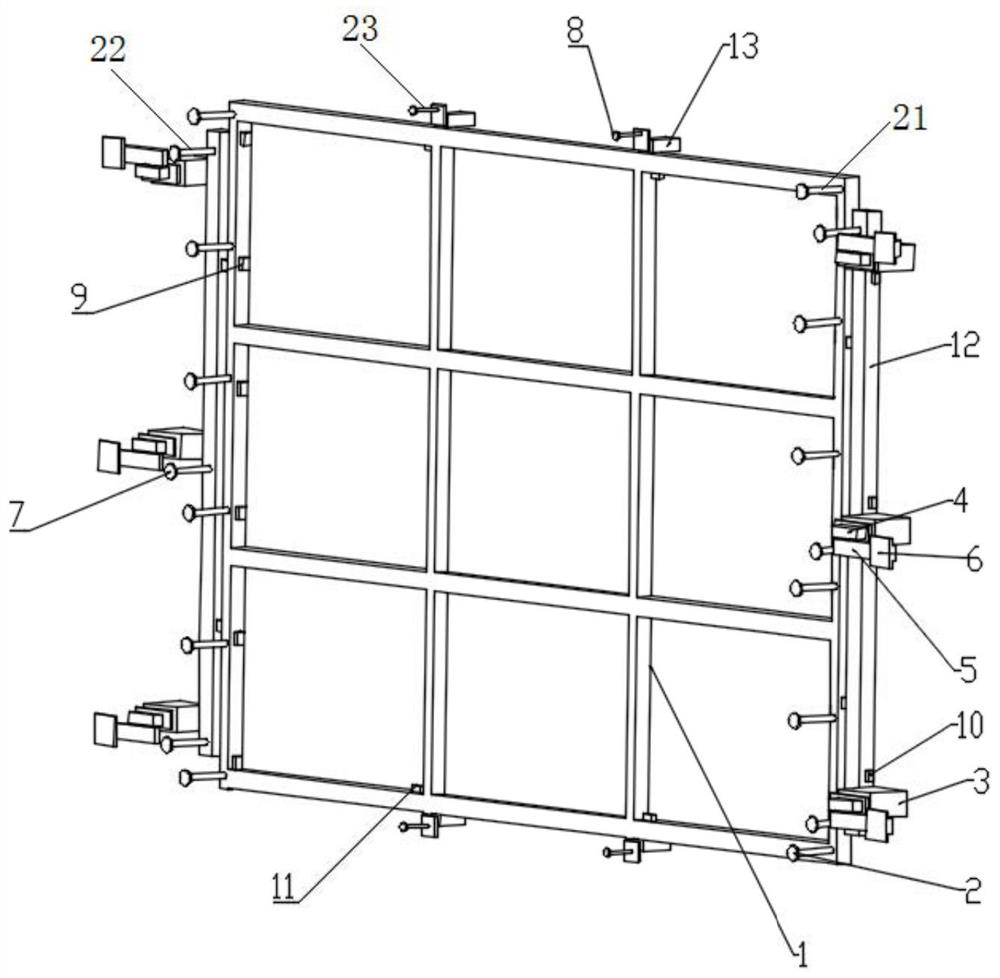

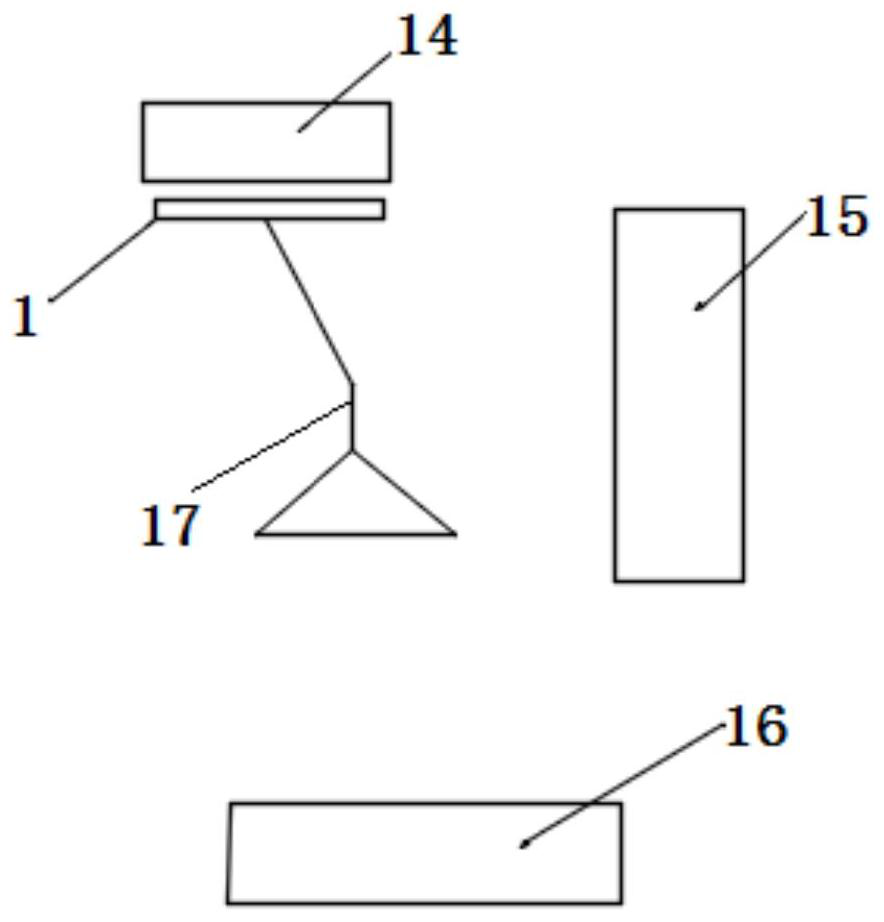

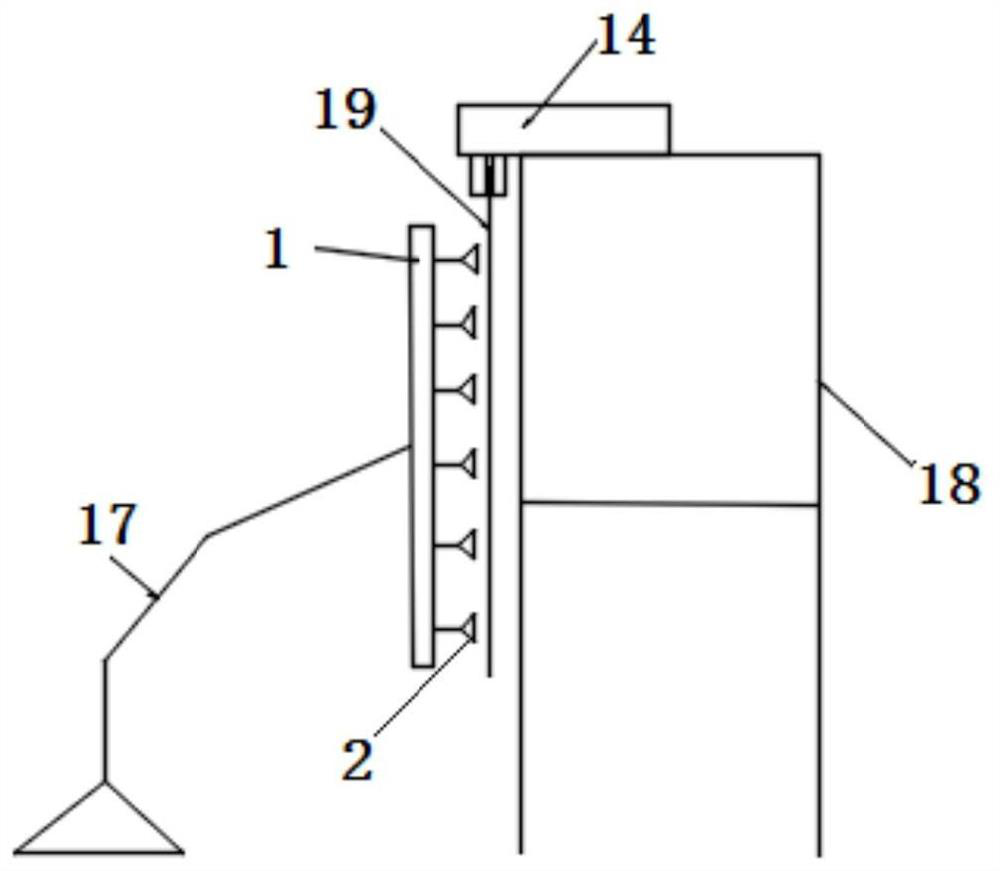

[0051] Such as figure 1 As shown, a glass plate and cellophane clamping device of the present invention includes a suction cup holder 1, a lower plate device and a paper fetching device; the suction cup holder 1 is a rectangular frame made of aluminum profiles of 40 × 40mm, and the suction cup holder 1 is 2400mm long. The width is 2000mm, and there are two horizontal and vertical aluminum profiles arranged in the shape of "well" to form a nine-square grid structure.

[0052] Six No. 1 suction cups 2 with suction cup rods are respectively distributed at intervals of 400 mm on the two frames of the suction cup frame 1 width direction, and No. 1 suction cup 2 is controlled by No. 1 vacuum generator 9 to establish vacuum and break vacuum.

[0053] Two lower plate cylinders 13 are respectively installed at the outer interval 800mm of two frames of the suction cup frame 1 length direction, and a No. 3 sucker 8 with a sucker bar is installed on the extension seat of each lower plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com