An electrolysis unit for gas production by electrolysis of water, device for gas production by electrolysis of water and its application, and process of gas production by electrolysis of water

An electrolysis unit and a technology of electrolysis of water, applied in the field of electrolysis, can solve problems such as unfavorable promotion and use of electrolysis technology and rising costs, and achieve the effects of improving market competitiveness, reducing efficiency loss, and producing gas at low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

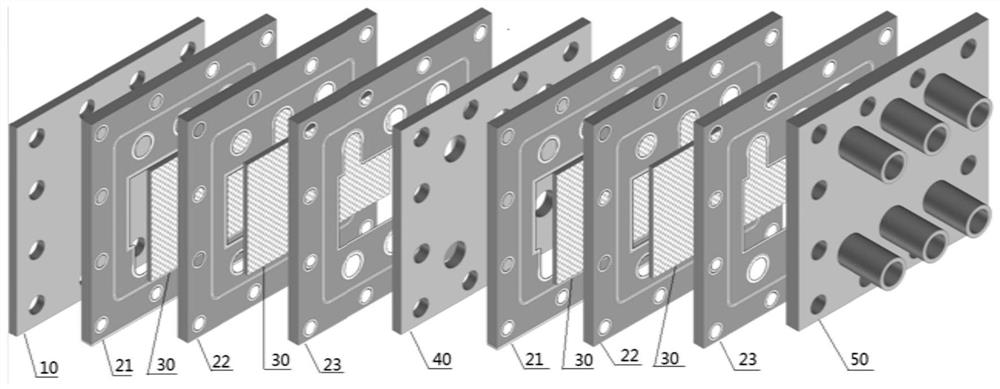

[0093] This embodiment provides an electrolyzed water gas production device, please refer to Figure 1 to Figure 10 , The electrolyzed water gas generating device includes 2 groups of electrolytic units (first electrolytic unit and second electrolytic unit), connecting plate 40, panel 50, bottom plate 10 and power supply (not shown).

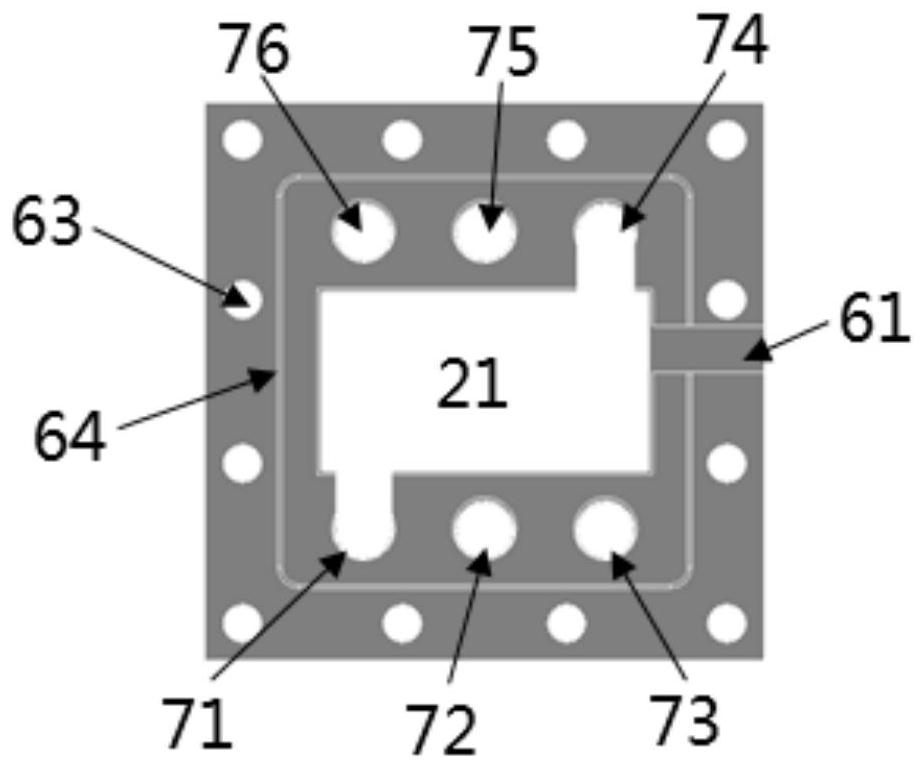

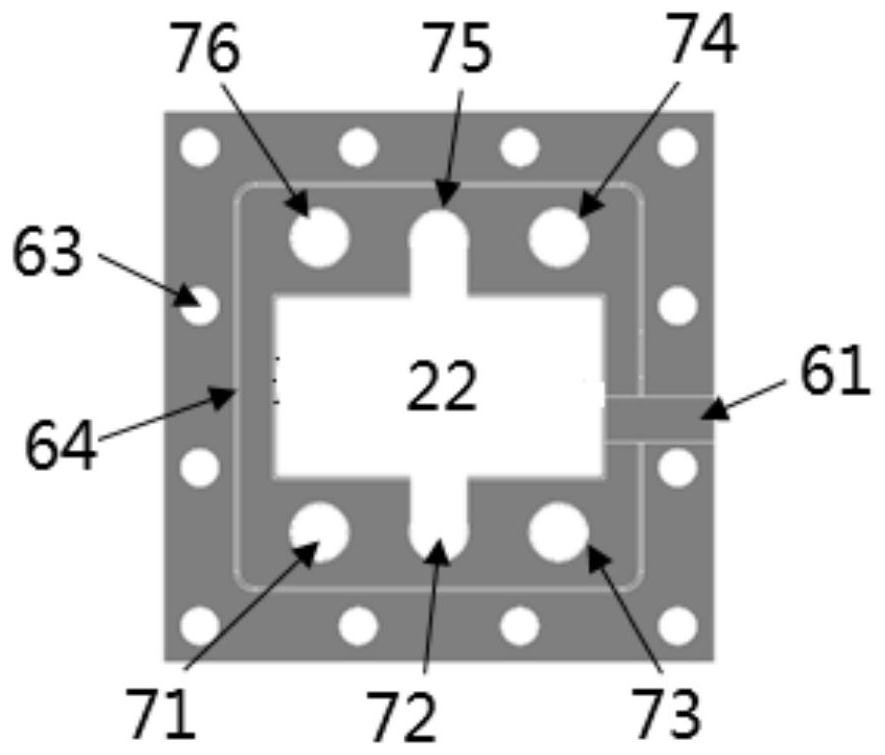

[0094] Wherein, each electrolysis unit all comprises first cathode 21, common anode 22 and second cathode 23, and first cathode 21 and second cathode 23 are arranged oppositely, and common anode 22 is arranged between first cathode 21 and second cathode 23 The sides of the common anode 22 are opposite to the first cathode 21 and the second cathode 23 respectively. A diaphragm 30 is provided between the common anode 22 and the two cathodes to separate each electrode into different electrolytic chambers. Each electrode plate is provided with terminal block 62 draw-in groove 61, is used for the first cathode piece 24 that cooperates respectively w...

Embodiment 2

[0103] The connecting plate 40 in this embodiment is made of polytetrafluoroethylene high insulating material. The connecting plate 40 separates the cathodes of adjacent electrolytic cells, and connects the anodes of the electrolytic cells to the first negative electrode 21 or the second negative electrode 23 of the next electrolytic cell in a step-by-step series connection, and finally connects the anode at one end of the electrolytic cell stack to the The positive pole of the power supply is connected, while the cathode at the other end is connected to the negative pole of the power supply to form a stack of electrolytic cells in series. The electrolyte enters from the three liquid inlets at the bottom of the right side panel 50, and enters the electrolysis unit through the channels at the bottom of each component, and the excess electrolyte and gas generated by electrolysis are collected and discharged at the top three liquid / gas channels. The three liquid inlet channels ca...

Embodiment 3

[0106] Please refer to Figure 11 to Figure 14 , the difference between this embodiment and Embodiment 1 is: the shape of the electrode plate is circular, the connection holes 63 are arranged at equal intervals along the circumference of the electrode plate, and two adjacent inlet holes and / or outlet holes are provided with A connecting hole 63.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com