Device and method for detecting a yarn empty bobbin

A detection method and technology of a visual detection device, applied in textiles and papermaking, etc., can solve the problems of no automatic detection and replacement of yarn empty drums, reduced production efficiency, unresolved detection and replacement of yarn empty drums, etc. Canister detection and canister change prompts, optimized scheduling, to achieve the effect of empty canister detection and canister change prompts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

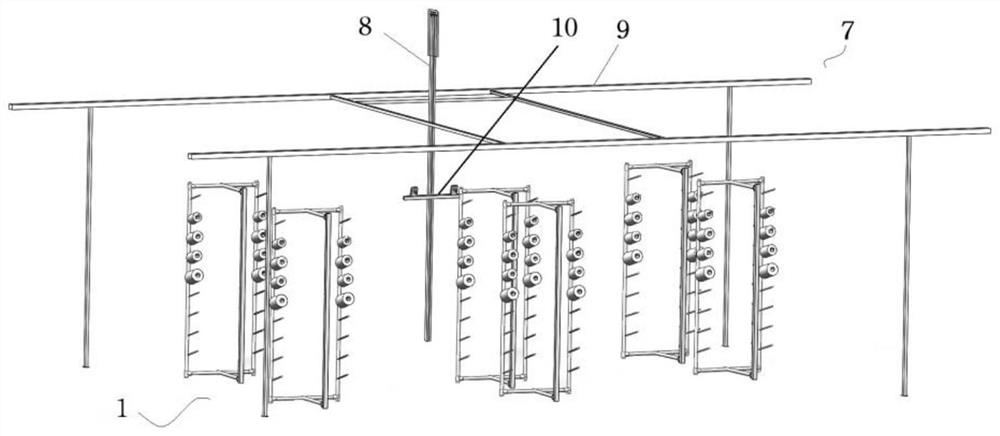

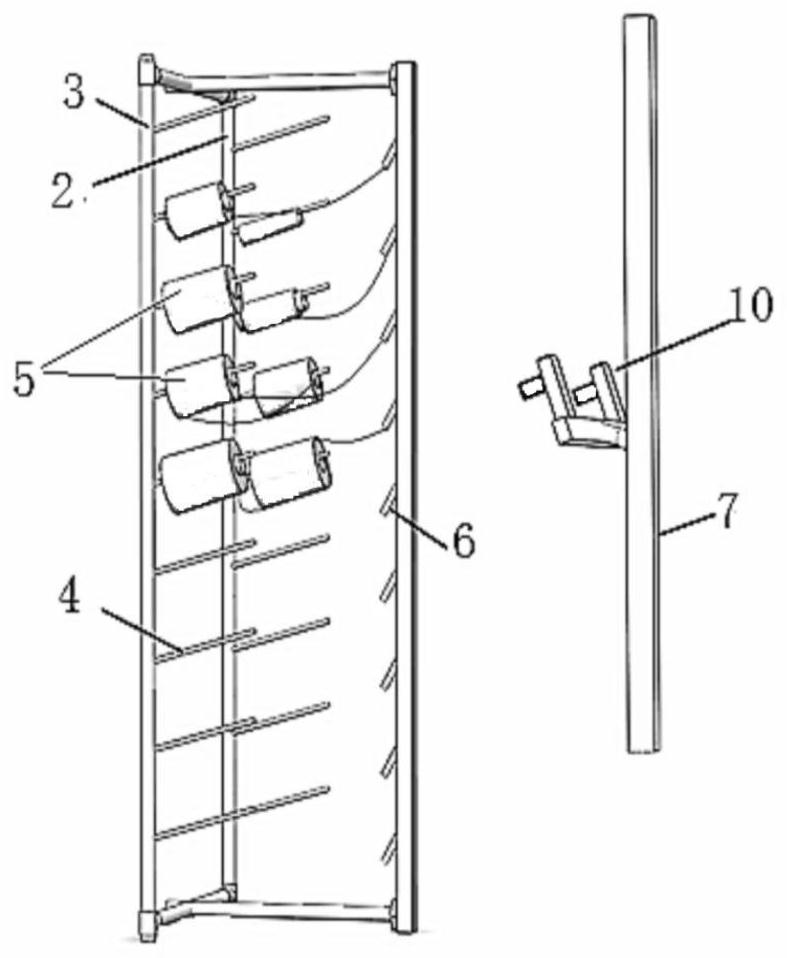

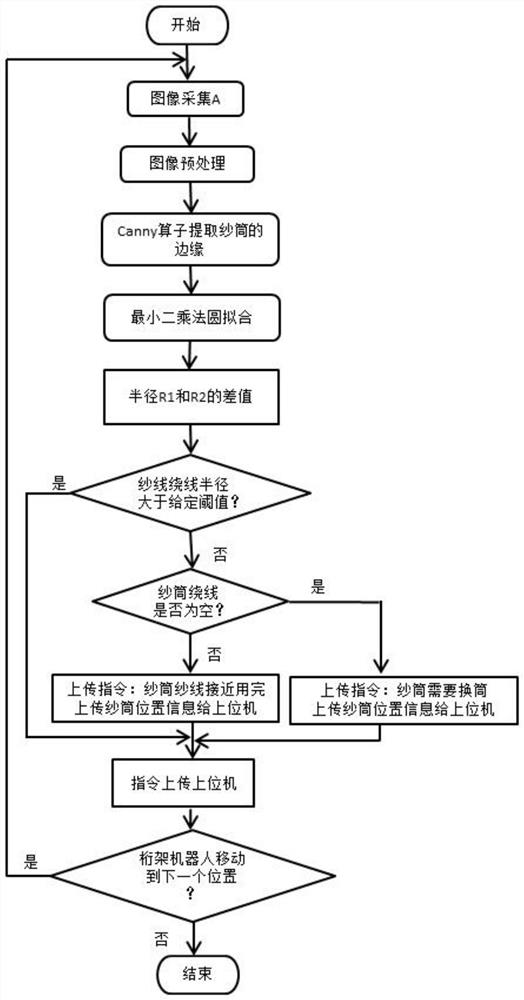

[0080] Such as figure 1 As shown, the yarn empty cylinder detection device is composed of eight-hole air-feeding yarn rack, binocular vision module, sliding guide rail, truss robot, wireless communication module, PC upper computer, display module, etc.

[0081] In the overall device, the upper computer assigns numbers to all eight-hole air-feeding creels No. 1, No. 2, No. 3, ..., and No. 9 (the specific number of eight-hole air-feeding creels can be specified according to actual working conditions). The yarn bobbins of each yarn delivery frame are divided into A and B columns, and the yarn bobbins of each column are numbered in Arabic numerals from top to bottom. Example: 1A1 means the first bobbin bar of the A column of No. 1 eight-hole air-feeding creel, and 3B7 means the seventh bobbin bar of the B-pillar of No. 3 eight-hole air-feeding creel. When an empty can is detected, the number is converted into a hexadecimal code and sent to the can changing robot for coordinate po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| frame rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com