An anchor injection structure

A technology of anchoring and bolting, which is applied in the installation of bolts, mining equipment, earthwork drilling and mining, etc. It can solve the problem that the anchoring force of the rock mass is not as good as that of the end anchor, so as to improve the shear resistance, improve the reliability, and suppress deformation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

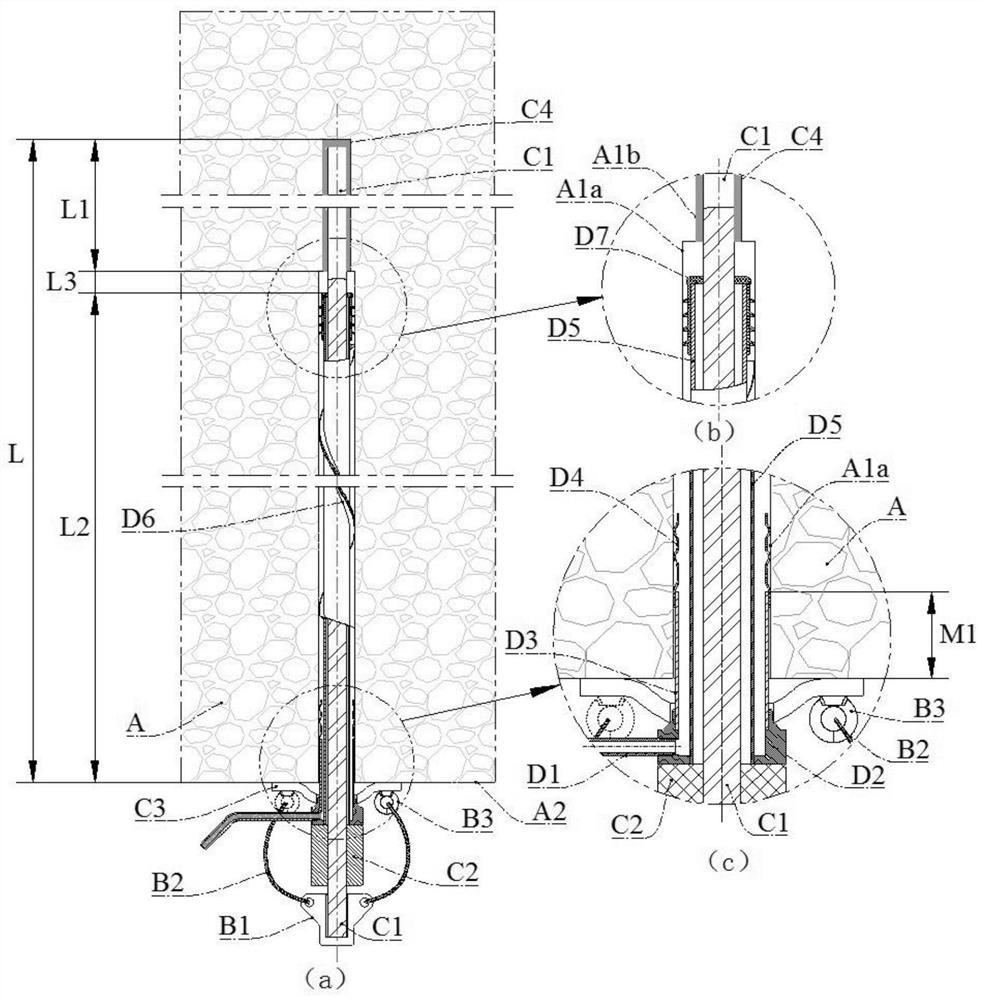

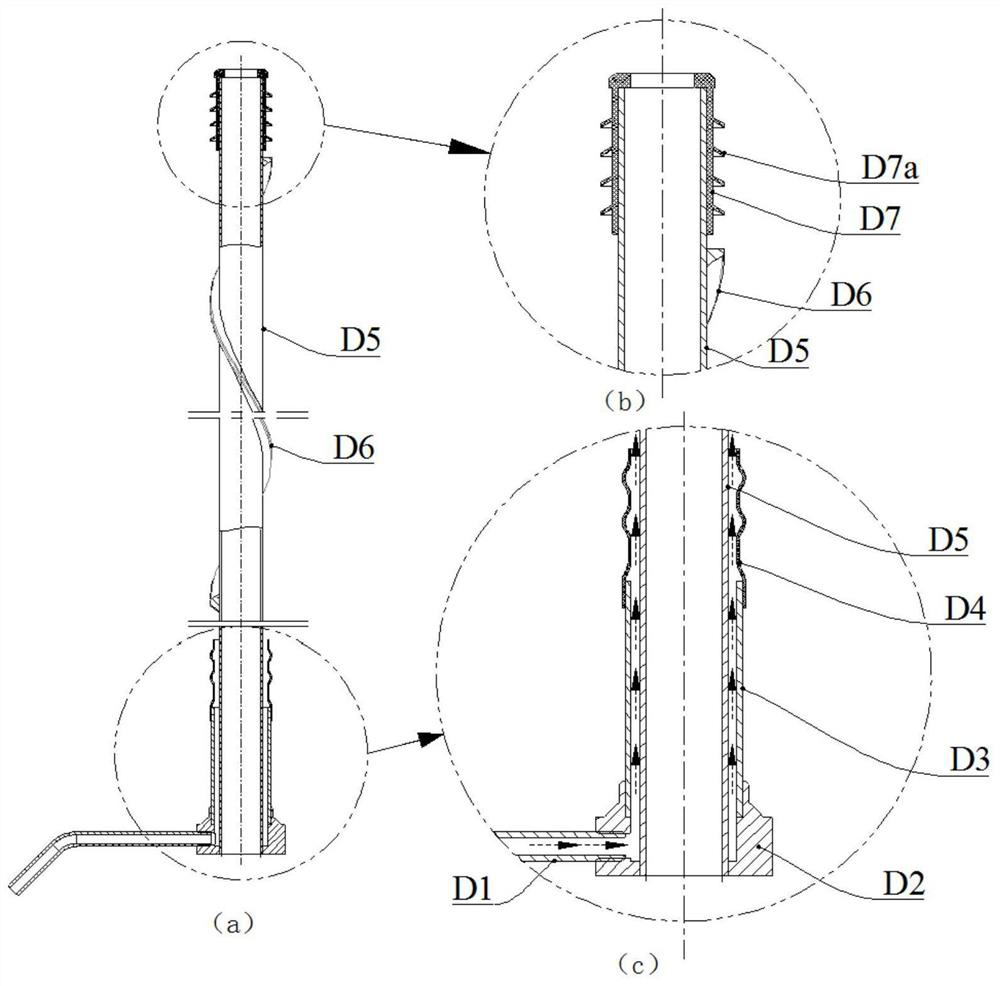

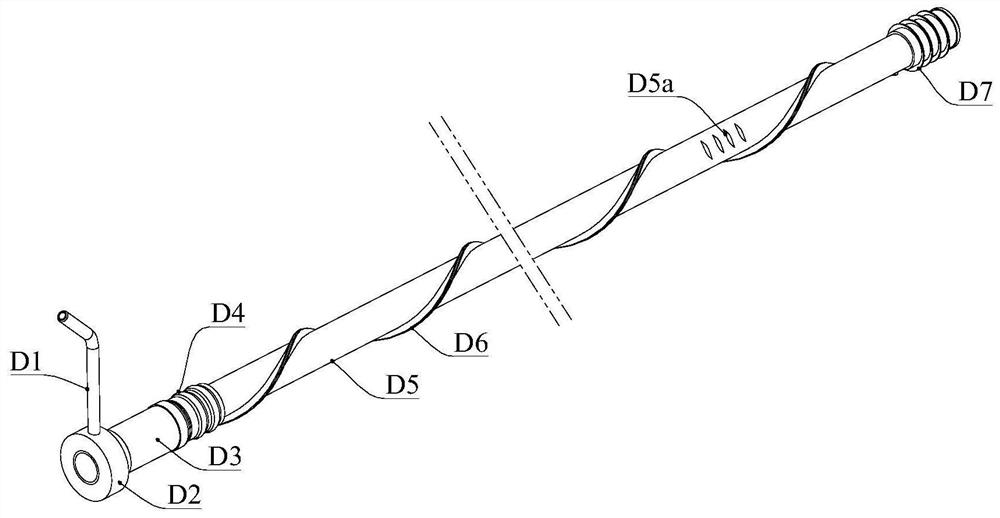

[0039] The following is based on Figure 1 to Figure 6 The specific embodiment of the present invention is further described:

[0040] Such as Figure 1 to Figure 6 As shown, this embodiment provides an anchoring structure, including an anchoring part C, a grouting part D and a protective part B.

[0041] Such as figure 1 As shown, the anchoring part C includes an anchor rod or anchor cable C1, a nut or lock C2, a tray C3 and an anchoring agent C4, and the anchor rod or anchor cable C1 is constructed in the rock mass A to be anchored through the anchoring agent C4 The small-diameter hole section A1b of the step anchor rod hole A1 is anchored, and the nut or lock C2 realizes the pre-tightening force for the anchor rod or the anchor cable C1 (if C1 is an anchor rod, then C2 is a nut, and there is a threaded connection between the two; If C1 is an anchor cable, then C2 is a lockset, and the two are connected by a mechanical barb structure), and the nut or lockset C2 exerts an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com