Constant-pressure grouting-water supply pneumatic combined servo control system for test

A servo control system, technology for testing, applied in the direction of control/regulation system, fluid pressure control, non-electric variable control, etc., can solve the problem of unable to monitor and adjust grouting parameters in real time, limit the development of grouting model tests, and grouting system Incompatibility and other problems, to achieve the effect of improving efficiency and reliability, compact structure, and comprehensive functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

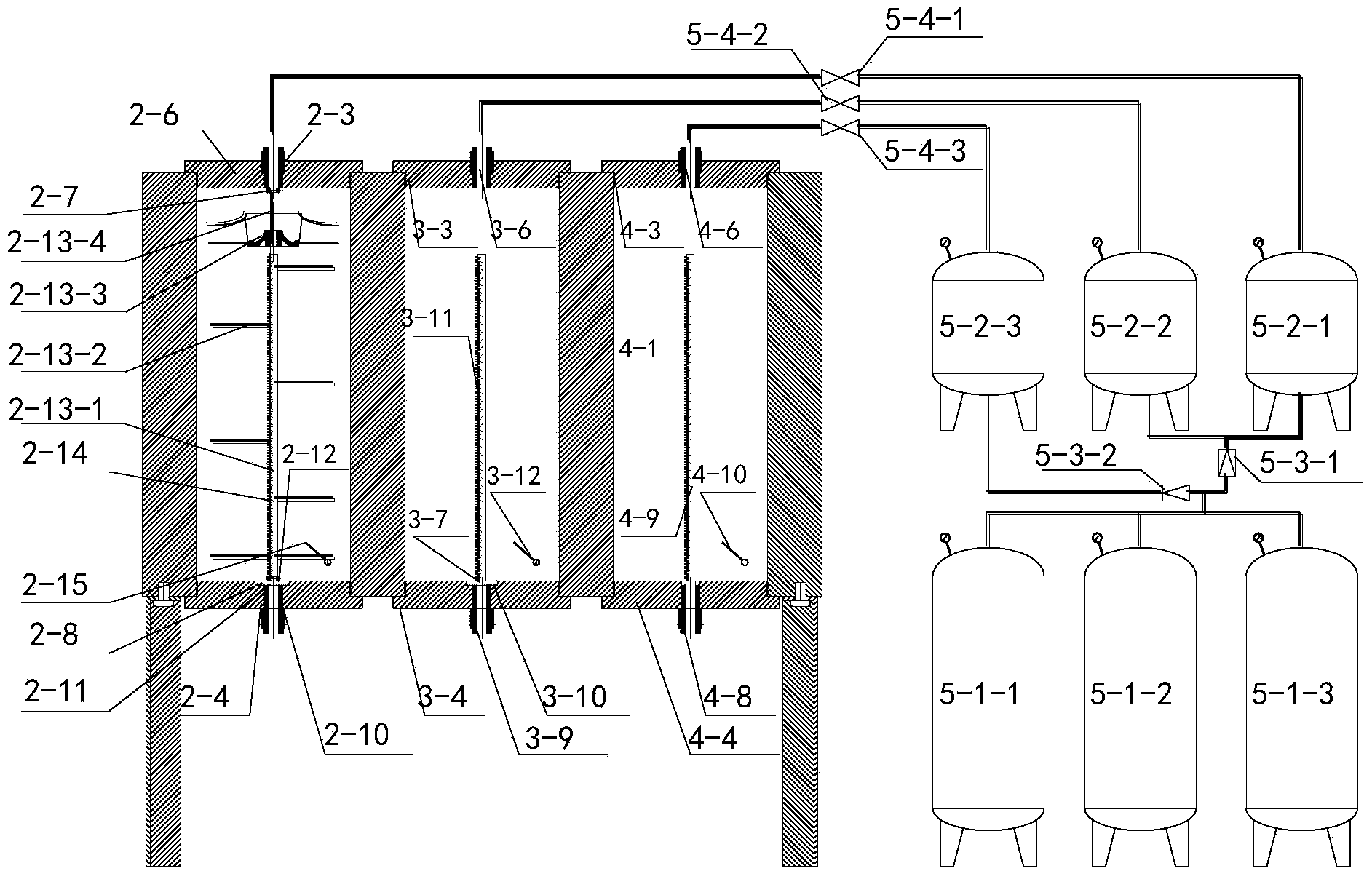

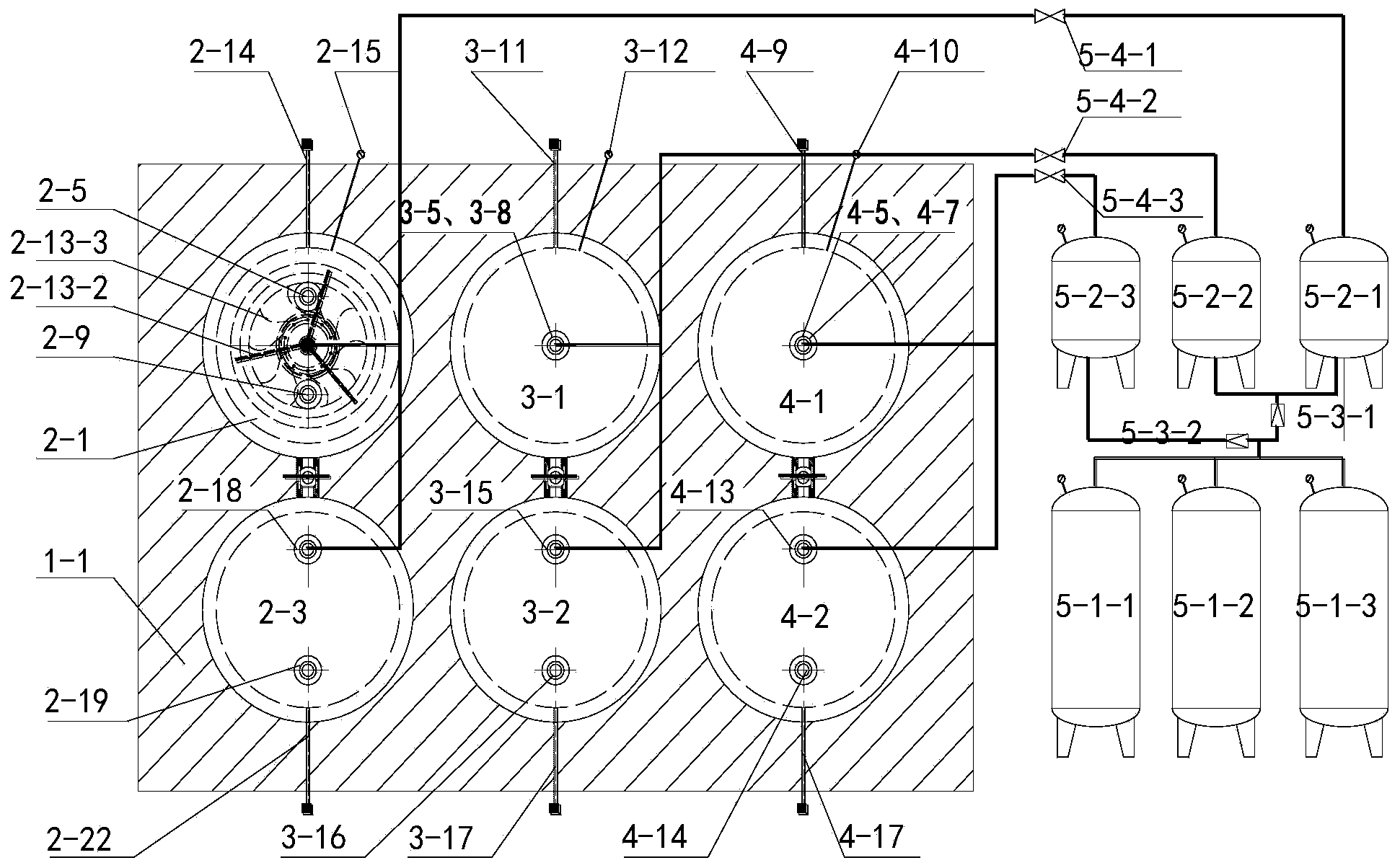

[0037] Such as figure 1 , figure 2 As shown, the overall frame 1-1 is made of phenolic resin material, the size is 910*640*550mm, and 6 cylindrical cavity structures of Φ200*550mm are processed inside. The cavity structure is divided into 3 groups, which are the first cavity Body group, second cavity group and third cavity group, the first cavity group is composed of cement-based material slurry storage cavity 2-1 and cement-based material slurry preparation cavity 2-2, the second cavity group is composed of chemical material The slurry storage cavity 3-1 is formed by the chemical material slurry preparation cavity 3-2, and the third cavity group is composed of the water storage cavity 4-1 and the water preparation cavity 4-2.

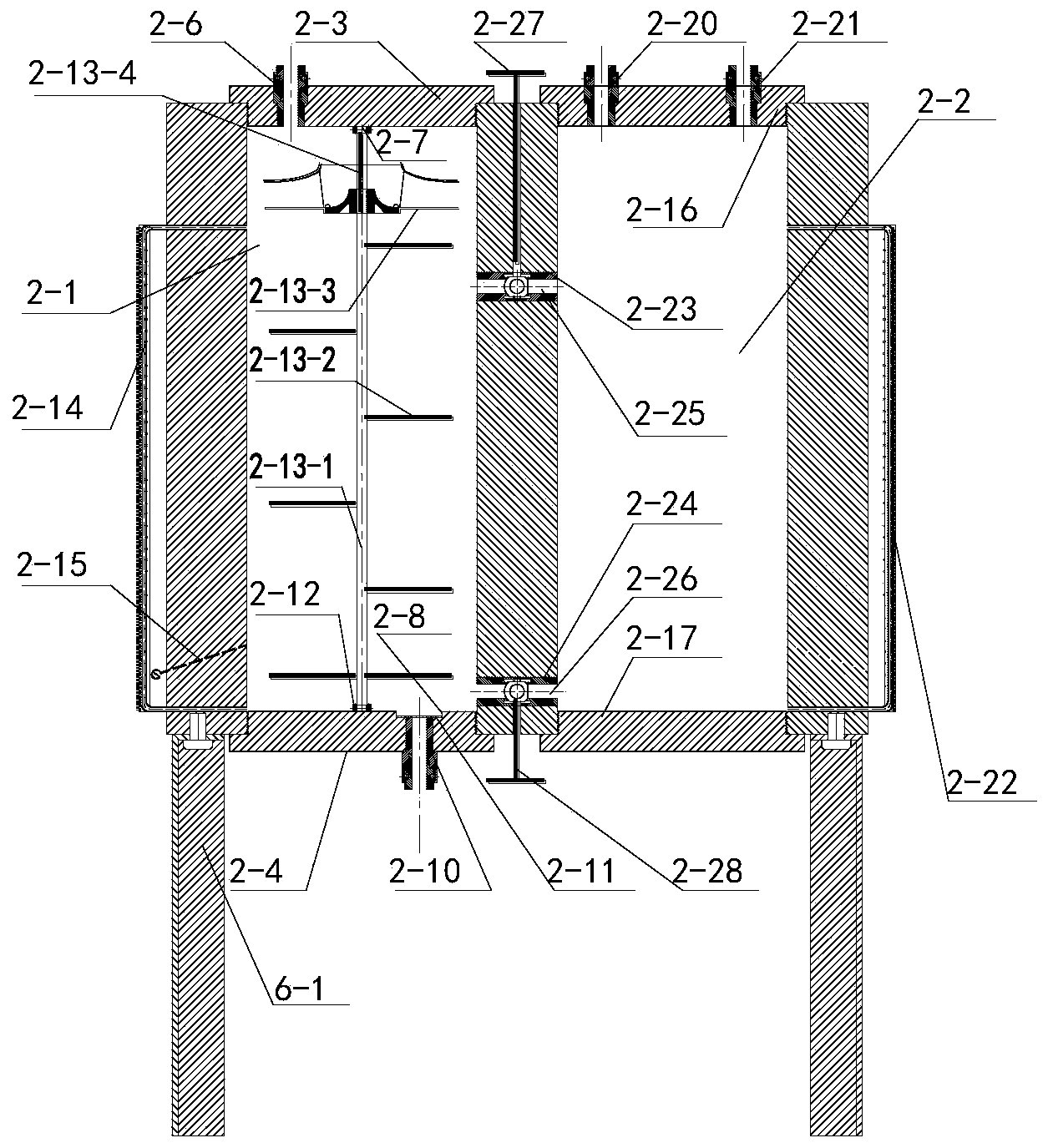

[0038] Such as figure 1 , figure 2 , image 3 As shown, the cement-based material slurry storage chamber 2-1 is connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com