Method for predicting fatigue life of secondary extrusion strengthened hole

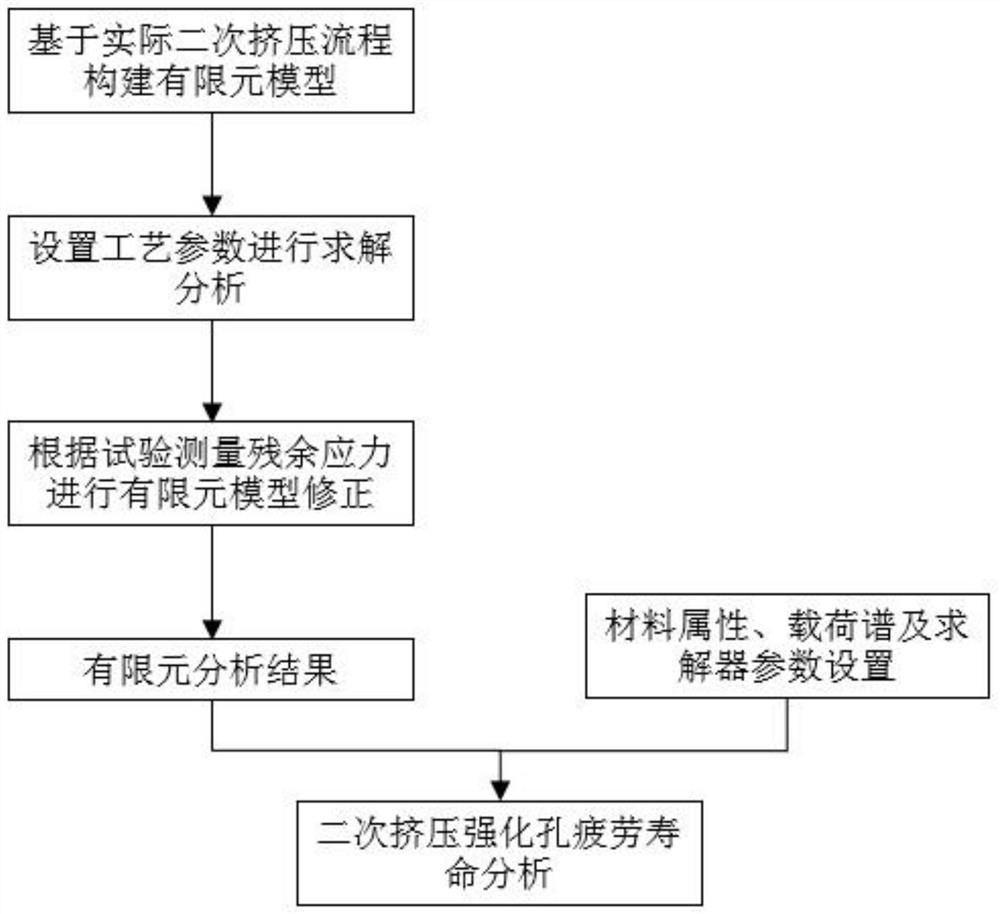

A fatigue life prediction and secondary extrusion technology, which is applied in design optimization/simulation, special data processing applications, instruments, etc., can solve the problem of no secondary extrusion strengthening hole fatigue life prediction method, etc., to reduce the number of tests and simulations cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The method for predicting the fatigue life of secondary extrusion strengthening holes of the present invention will be specifically described below with application examples.

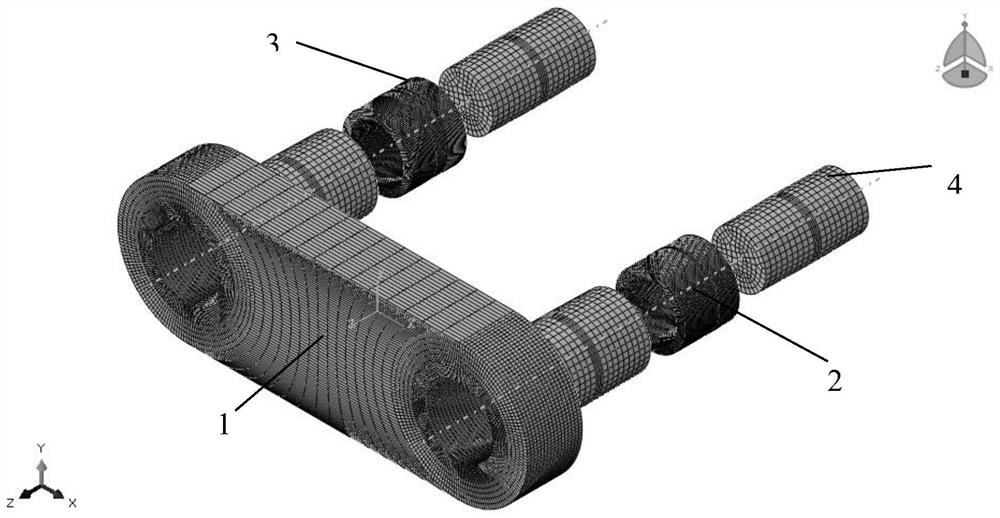

[0037] The actual working condition in this embodiment is that M42 high-cobalt steel mandrel is used to extrude TB6 titanium alloy lug 1 and 1Cr17Ni3A stainless steel bushing 2, wherein the diameter of the bottom hole of the lug is 20 mm, and the diameter of the working section of mandrel 3 for one extrusion is 20.4mm, corresponding to a relative extrusion amount of 2%, the relative extrusion amount used by the bushing 2 is 1.5%-2%.

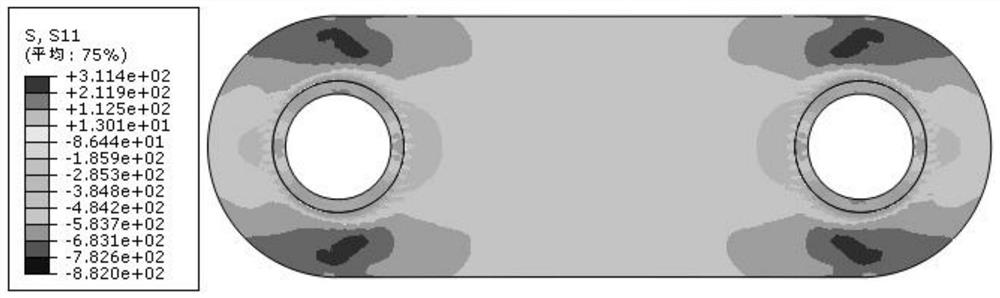

[0038] (1) First, use the finite element analysis software ABAQUS to establish the secondary extrusion strengthening finite element model according to the actual working conditions. The model consists of lug 1, bushing 2, primary extrusion mandrel 3 and secondary extrusion mandrel 4. Component composition, in the process of extrusion strengthening, firstly extrude t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com