Conventional perforating and fertilizing vehicle for green land

A fertilization vehicle and green space technology, applied in fertilization devices, planting methods, fertilizer distributors, etc., can solve the problems of high technical requirements for operators, high labor cost consumption, and a large number of manpower operations, so as to reduce technical requirements and labor costs , the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with specific embodiments and accompanying drawings, so as to help understand the content of the present invention.

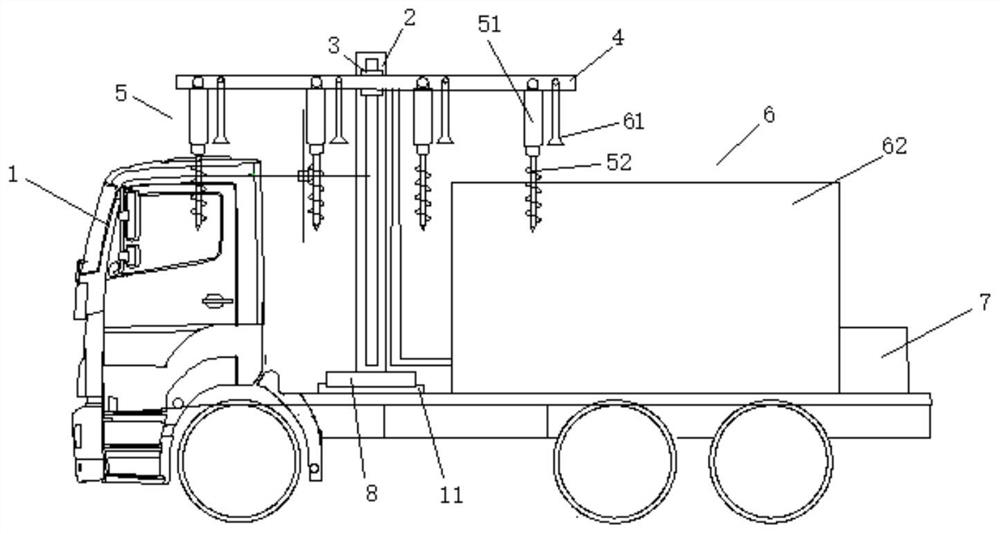

[0016] Such as figure 1 As shown, a conventional green field perforating and fertilizing vehicle provided by the present invention includes a vehicle body 1 and a controller, and also includes a vertical column 2 that slides along a slide rail 11 provided in the width direction of the vehicle body, and the vertical column 2 is arranged on Between the car body 1 and the fertilization box 62, the car body 1 is slidably connected through the rotating device 8, and the rotating device 8 is electrically connected to the controller; Connected punching mechanism 5 and fertilization mechanism 6; The slide table 3 is driven by a servo motor, the punching mechanism 5 includes at least one drill rod 52 and a motor 51, the drill rod 52 is driven by the motor 51, and the fertilization mechanism 6 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com