Glutinous rice cake beating device for food processing

A food processing and glutinous rice cake technology, which is applied in the field of glutinous rice cake making devices for food processing, can solve the problems of time-consuming, laborious and difficult operation, and achieve the effect of reducing the difficulty of operation and better effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

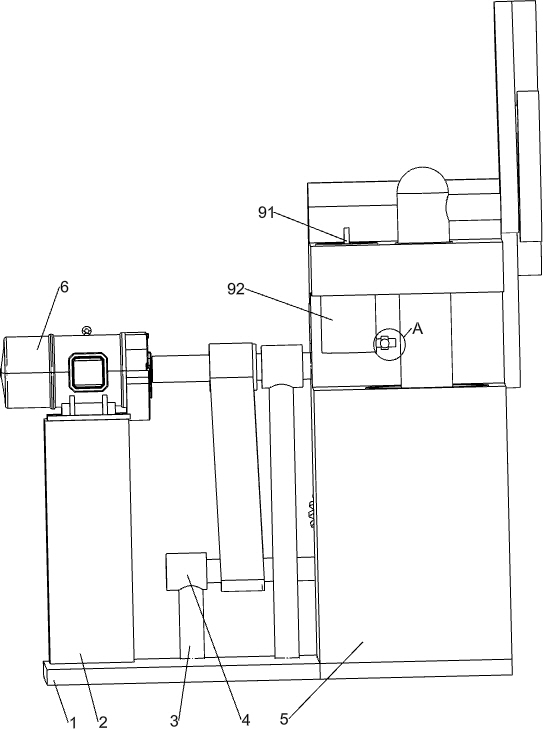

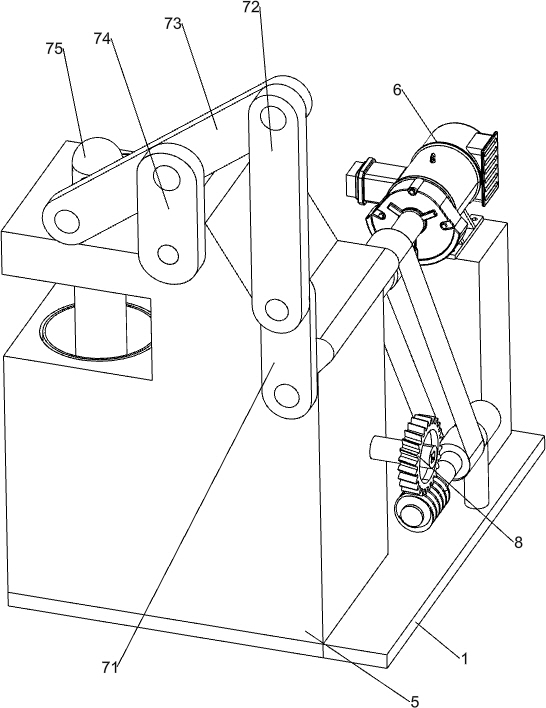

[0025] A kind of food processing device for beating glutinous rice cakes, such as figure 1 As shown, it includes a base plate 1, a support column 2, a guide column 3, a guide sleeve 4, a support platform 5, a transmission mechanism 6, a beating mechanism 7 and a rotating mechanism 8, and the left front side of the top of the base plate 1 is equipped with a support column 2, and the base plate 1 A guide column 3 is installed on the left side of the top, a guide sleeve 4 is connected to the top of the guide column 3, a support platform 5 is installed on the rear side of the top of the bottom plate 1, a transmission mechanism 6 is connected between the support column 2 and the support platform 5, and the support platform 5 is connected There is a beating mechanism 7, and a rotating mechanism 8 is connected between the supporting platform 5 and the transmission mechanism 6, and the transmission mechanism 6 is respectively matched with the beating mechanism 7 and the rotating mechan...

Embodiment 2

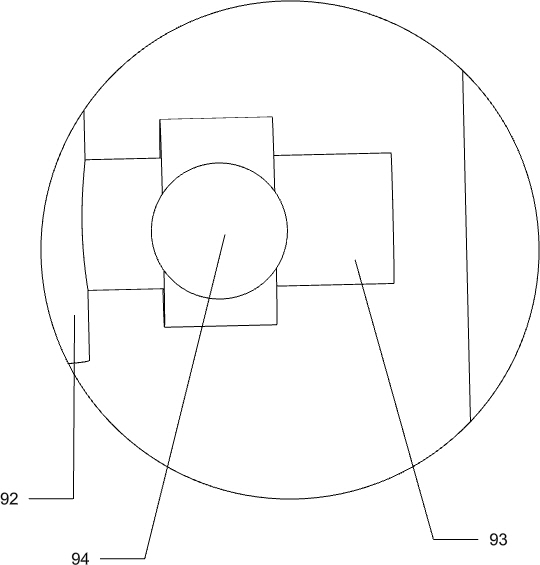

[0031] On the basis of Embodiment 1, such as Figure 4 and Figure 5 Shown, also include water adding mechanism 9, water adding mechanism 9 includes bucket cover 91, water adding bucket 92, outlet pipe 93 and valve 94, and the right front side of support platform 5 top is equipped with water adding bucket 92, and adding water bucket 92 runs through support platform 5 , add bucket 92 to be provided with bucket lid 91, add water bucket 92 bottom outer side walls to be connected with outlet pipe 93, valve 94 is installed on the outlet pipe 93.

[0032] In the process of making glutinous rice cakes, at the beginning, the valve 94 is in a closed state, people open the bucket cover 91 and pour water into the bucket 92, cover the bucket lid 91, and when it is necessary to add water to the glutinous rice cakes, people open the valve 94 and add water buckets The water in the 92 flows into the glutinous rice cake barrel 85 from outlet pipe 93 thereupon, when needing to add water, peopl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com