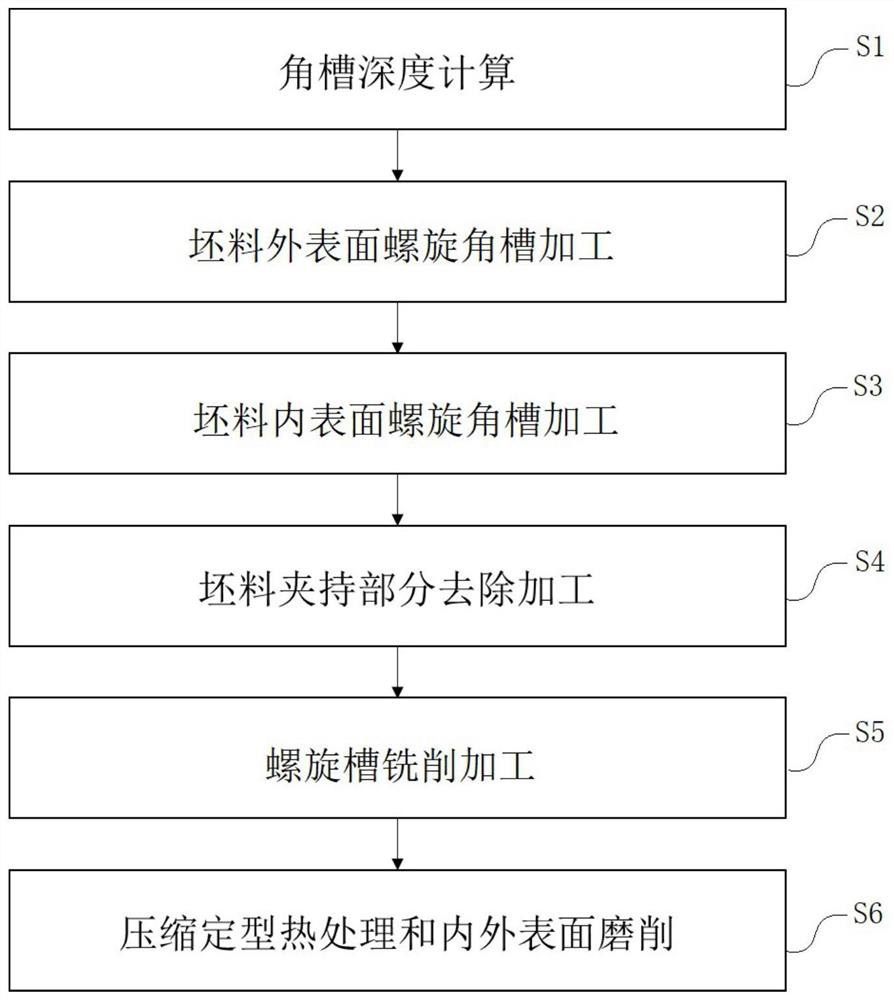

A processing method for special-shaped springs with inner and outer chamfers

A special-shaped spring and processing method technology, applied in the field of special-shaped spring machining, can solve the problems of high cost, low efficiency, difficult to guarantee the quality of chamfering, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0043] Explain the technical terms appearing in the examples.

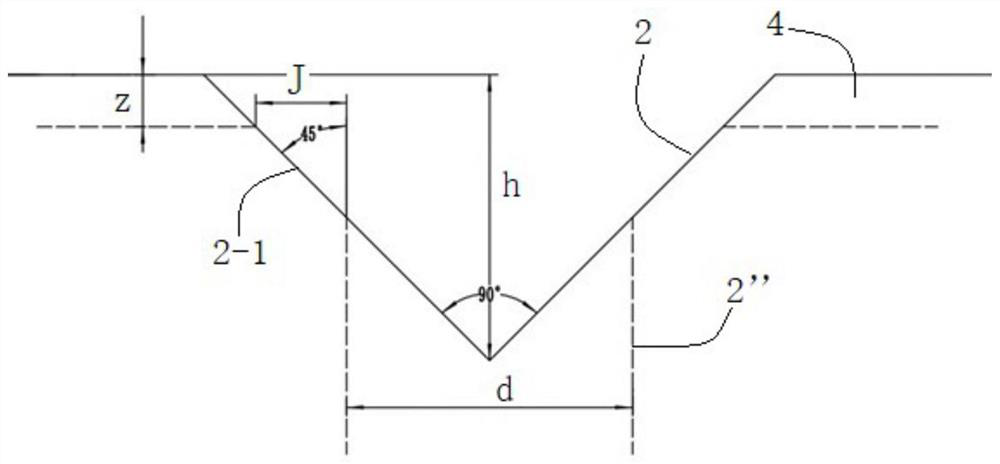

[0044] Helical corner grooves on the outer surface and helical corner grooves on the inner surface: helical corner grooves processed on the surface of the spring blank including chamfered slopes on both sides of the spring pitch gap;

[0045] Spiral groove: A spiral groove is machined on the spring blank through the outer surface and the inner surface to form a spring pitch gap;

[0046] Helix: the midline trajectory of the helical gap on the special-shaped spring;

[0047] Spring blank: the blank workpiece before machining the spiral groove;

[0048] Spring semi-finished product: the blank workpiece after processing the spiral groove, the spiral gap formed by processing is larger than the standard spiral gap of the spring product.

[0049] see figure 1 , the variable cross-section special-shaped spring in the figure is a special-shaped spring product used in clutches. Its two ends have equal pitch, and the num...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com