Electric power system and control method therefor

A power system and relay control technology, applied to batteries, circuits, collectors, etc., can solve problems such as time increase and pre-charging time increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

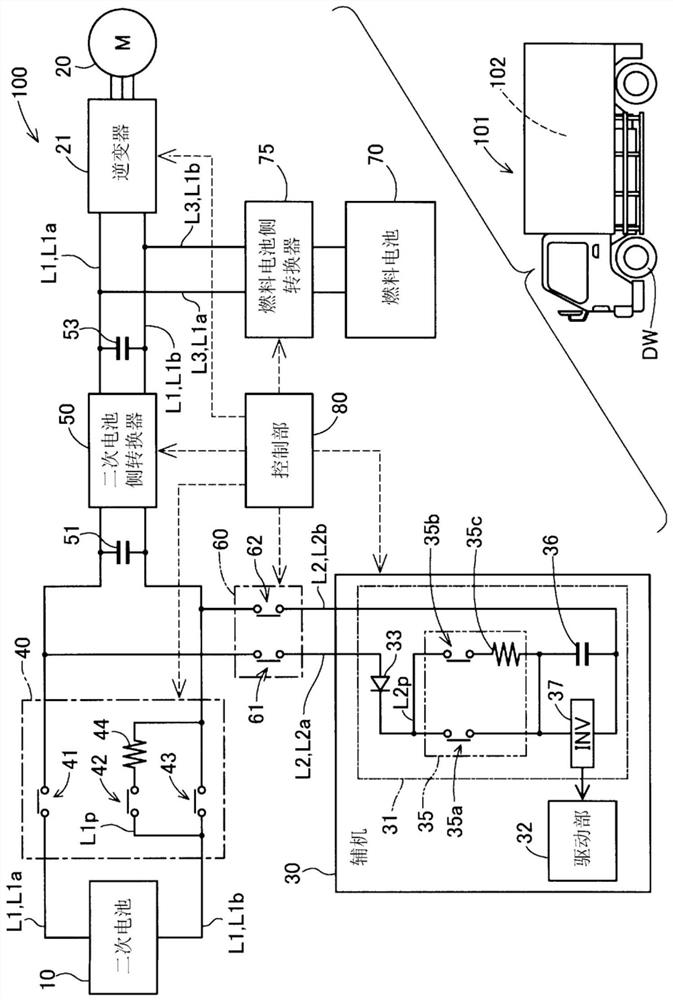

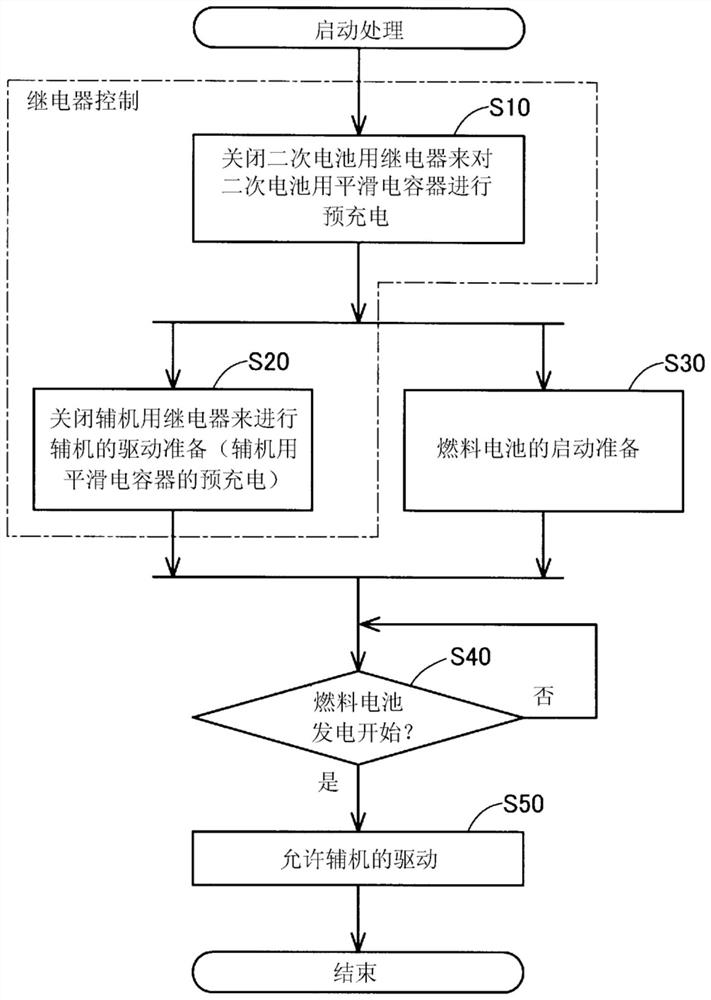

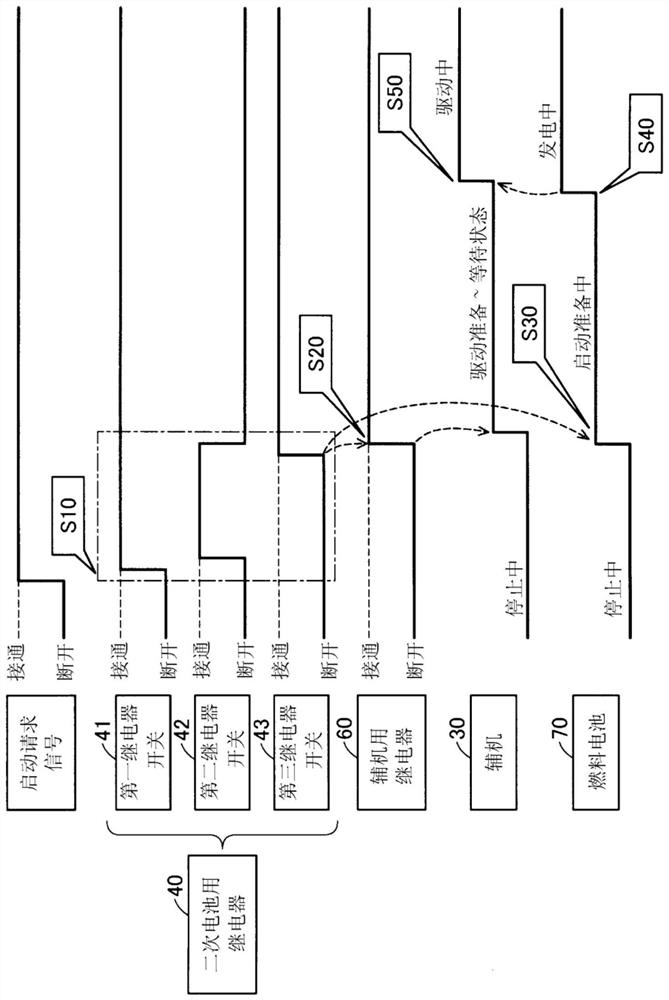

[0018] figure 1 It is a schematic diagram showing the structure of the electric power system 100 in this embodiment. The electric power system 100 is mounted on a vehicle 101 . The power system 100 includes a secondary battery 10 , and supplies electric power from the secondary battery 10 to a drive motor 20 that generates driving force of the vehicle 101 and an auxiliary machine 30 used by the vehicle 101 . However, the vehicle 101 of the present embodiment is a fuel cell vehicle, and the drive motor 20 is driven using the output power of the secondary battery 10 and the output power of the fuel cell 70 as will be described later.

[0019] As the secondary battery 10, for example, a lithium ion battery can be used. The secondary battery 10 is connected to the first DC line L1. The first DC conductor L1 includes a first high-voltage-side conductor L1a connected to the positive-side terminal of the secondary battery 10 and a first low-voltage-side conductor L1b connected to ...

Embodiment approach 1

[0056] In the above-described embodiment, the power system 100 may be provided with a power generation device other than the fuel cell 70 instead of the fuel cell 70 . The power system 100 may include, for example, a power generation device that generates power with an internal combustion engine, and a solar panel as a power generation device that generates power to be supplied to the drive motor 20 . In addition, the power system 100 may not include such a power generating device, and may be configured to drive the drive motor 20 and the auxiliary machine 30 using only the power of the secondary battery 10 charged by external power supply. In the startup process of the electric power system 100, steps S30 and S40 can be omitted.

Embodiment approach 2

[0058] In the above embodiments, the auxiliary machine 30 may not be a refrigerator. The auxiliary machine 30 may be constituted by other devices driven by various high voltages, and may be constituted by heavy equipment such as a crane, for example. In addition, the power system 100 may be connected to a plurality of auxiliary machines 30 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com