Pneumatic brake device capable of being circularly used

A technology of pneumatic brakes and cylinders, which is used in transportation and packaging, coiling strips, thin material handling, etc., can solve the problems of increased maintenance costs, increased labor of maintenance personnel, easily damaged brake friction blocks, and reduced machine work efficiency. , to avoid damage to the friction block, avoid mechanical wear and save time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

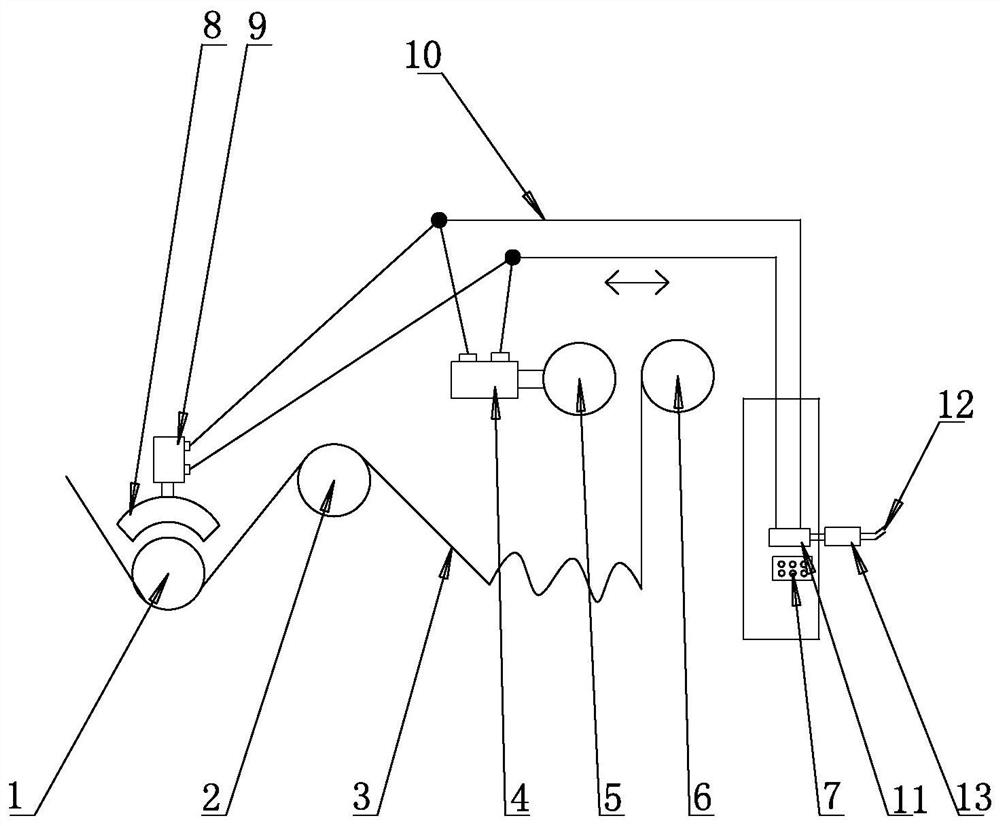

[0017] Such as figure 1 As shown, the embodiment of the recyclable pneumatic braking device of the present invention includes a textile machine, the textile machine is provided with a console 7, and one side of the console 7 is provided with a second traction roller 6, and the second traction roller 6 The side away from the console 7 is provided with a first traction roller 5, and the side of the first traction roller 5 away from the console 7 is provided with a cloth guide roller 1, and the cloth guide roller 1 is connected with a cylinder 9 through a brake friction block 8, so The console 7 described above is connected to the air cylinder 9 and the traction cylinder 4 through the air pipe 10 . The cloth 3 is connected with the second traction roller 6, between the emergency stop groove 2 and the cloth guide roller 1.

[0018] An emergency stop groove 2 is provided between the first traction roller 5 and the cloth guide roller 1 .

[0019] The console 7 is provided with a r...

Embodiment 2

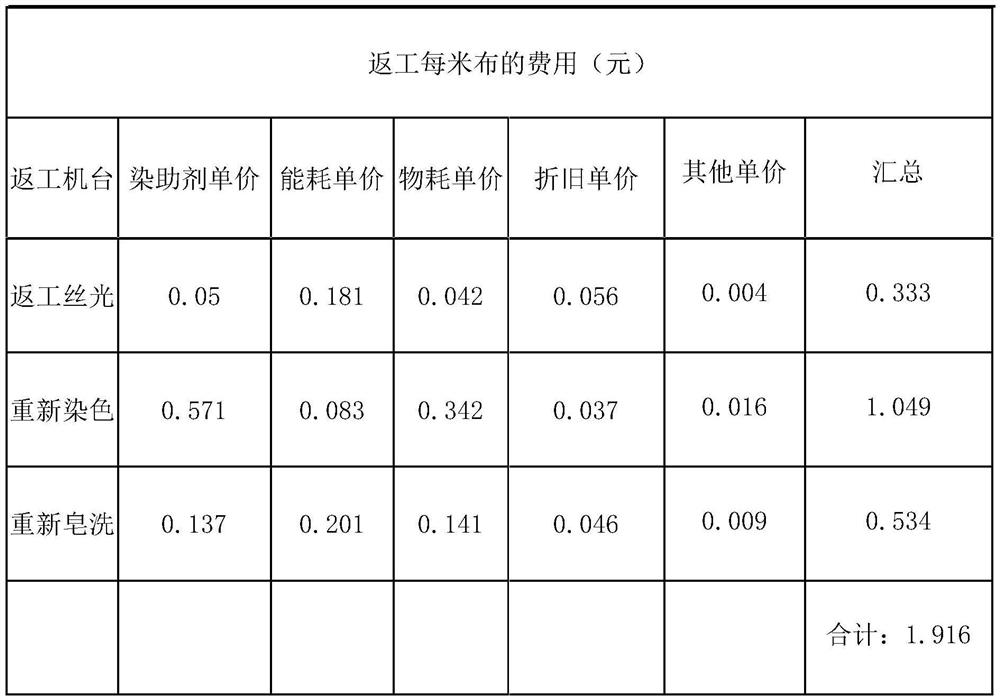

[0022] cost calculation:

[0023]

[0024] 1. It is calculated that the cost of reworking one meter of cloth3 is about 1.916 yuan

[0025] 2. After using the pneumatic brake, the number of head and tail creases is significantly reduced, the rework rate is reduced by 90%, the corresponding cost is also reduced, and the machine operation rate is increased.

[0026] 3. The self-made pneumatic brake can adjust the braking force and is not easy to be damaged. It only needs to replace the brake friction block 8, which costs about two yuan each.

[0027] Working process or working principle:

[0028] The external compressed air enters the pressure regulating valve 13 and the reversing valve 11 in turn through the air inlet 12, and is introduced into the cylinder 9 and the traction cylinder 4 through the air pipe 10, and the piston on the cylinder pushes the brake friction block 8 out to make the brake friction block 8 is tightly connected with the cloth guide roller 1 roll surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com