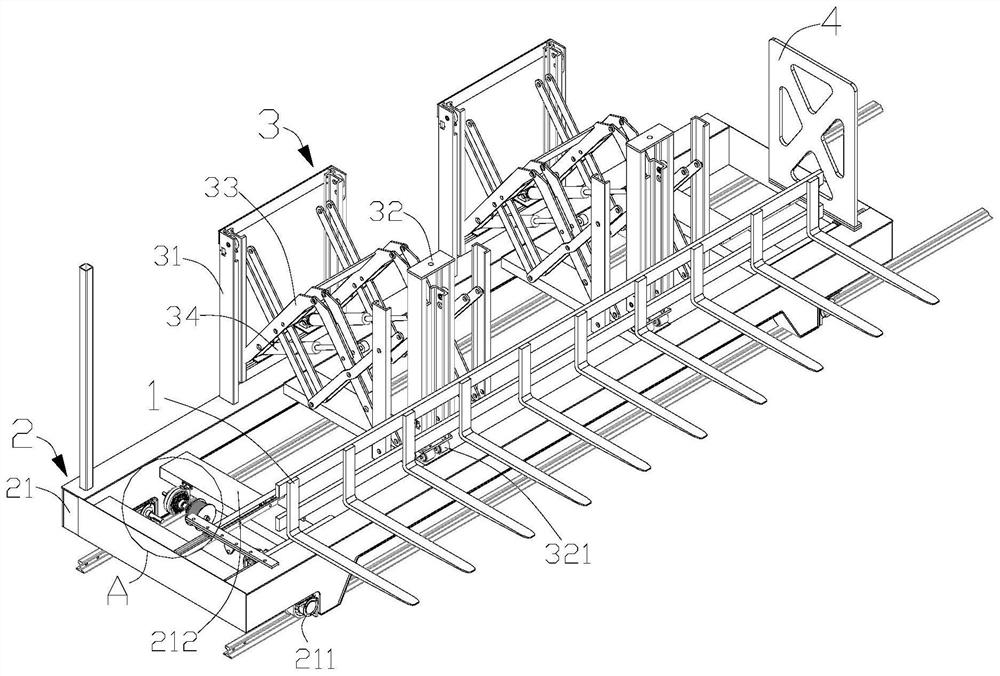

Cargo transportation loading system

A cargo transportation and fork rack technology, applied in the field of industrial handling vehicles, can solve the problems of low safety, multi-power maneuvering space, large vehicle volume, etc., and achieves accurate cargo placement, smooth and fast handling, and small vehicle volume. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

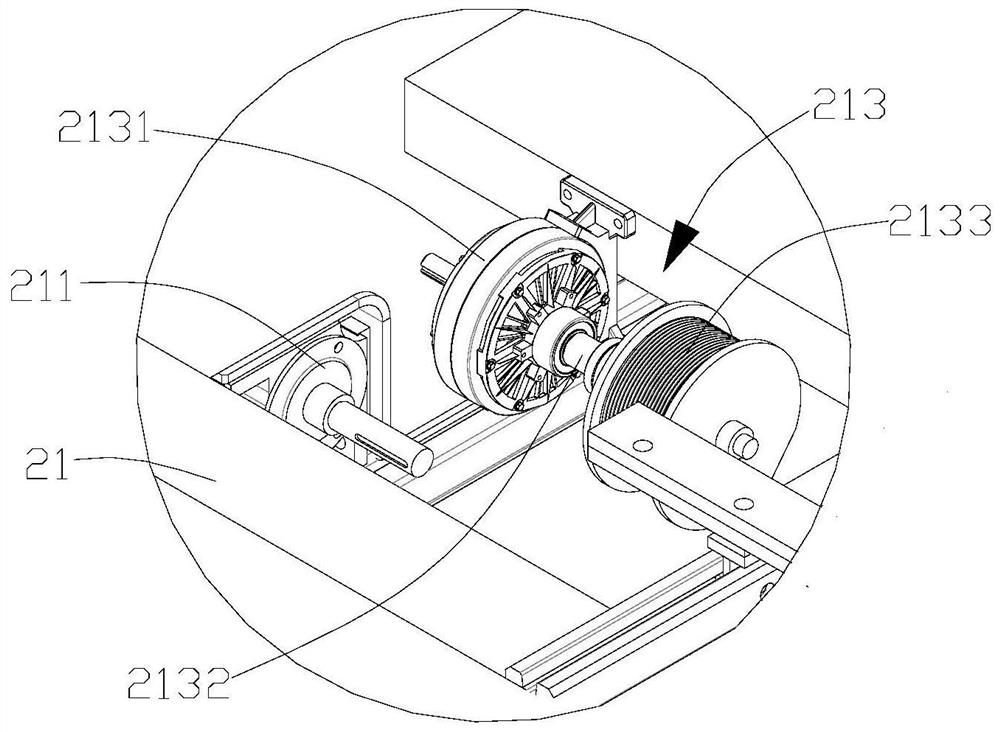

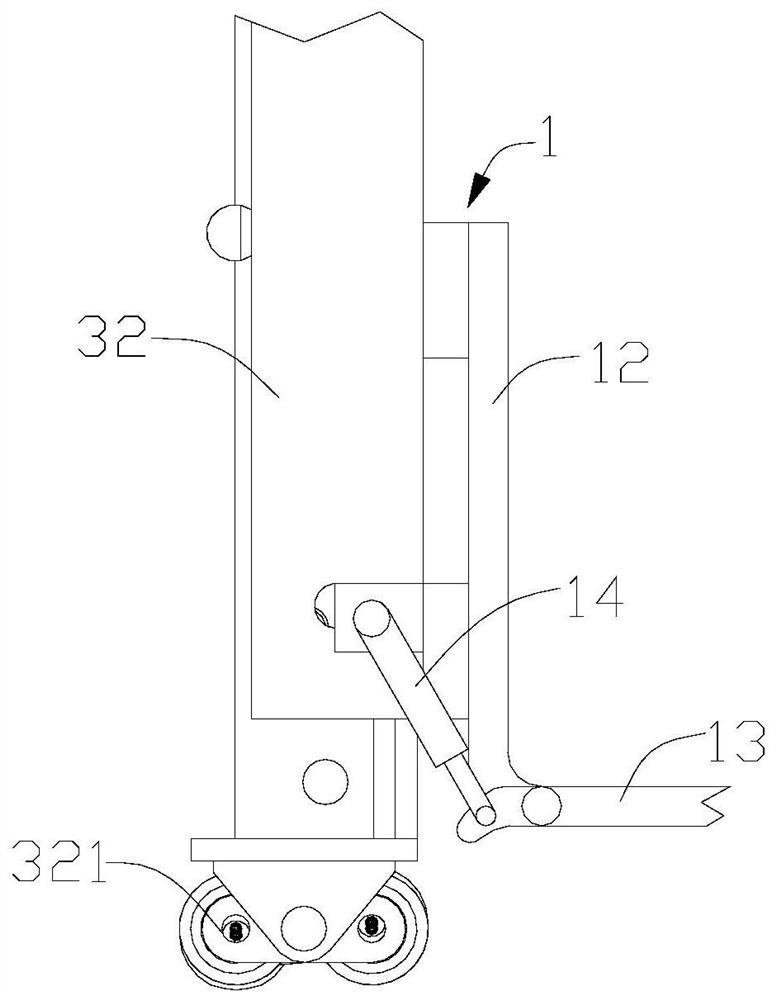

[0035] The implementation of the present invention will be described in detail below in conjunction with the drawings and examples, so as to fully understand and implement the process of how to apply technical means to solve technical problems and achieve technical effects in the present invention. Specific examples describing components and configurations simplify the disclosure to facilitate understanding. Of course, this is merely an example and not intended to be limiting. For example, references below to a first component being formed "over" or "on" a second component may include embodiments in which the first and second components are formed in direct contact, and may also include references to the first and second components. Embodiments where additional components are formed between components such that the first and second components may not be in direct contact.

[0036] In addition, for ease of description, spatially relative terms (such as "upper", "lower", "left"...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com