Flexible double-sided adhesive tape and preparation process thereof

A double-sided adhesive tape and preparation technology, which is applied in the direction of adhesives, film/sheet adhesives, adhesive additives, etc., can solve the problems of affecting appearance, large peeling force, and failure to meet the needs of folding screen links, etc., to achieve The effect of reducing the risk of folding breakage, good bending resistance, and reducing the risk of foreign matter adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in conjunction with specific embodiments.

[0028] This embodiment provides a flexible double-sided adhesive tape, the flexible double-sided adhesive tape comprises a first release film, a first adhesive layer, a base layer, a second adhesive layer and a second release film sequentially from one side to the other, The base layer is a TPU base film layer.

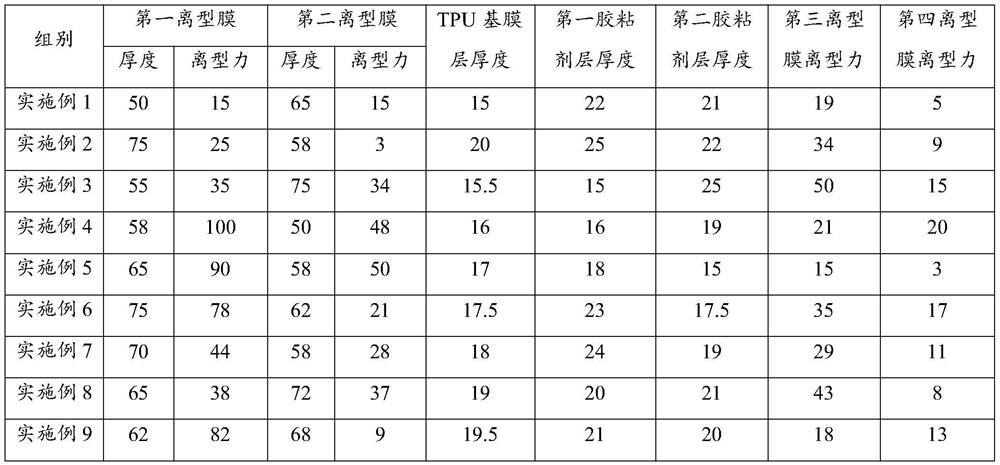

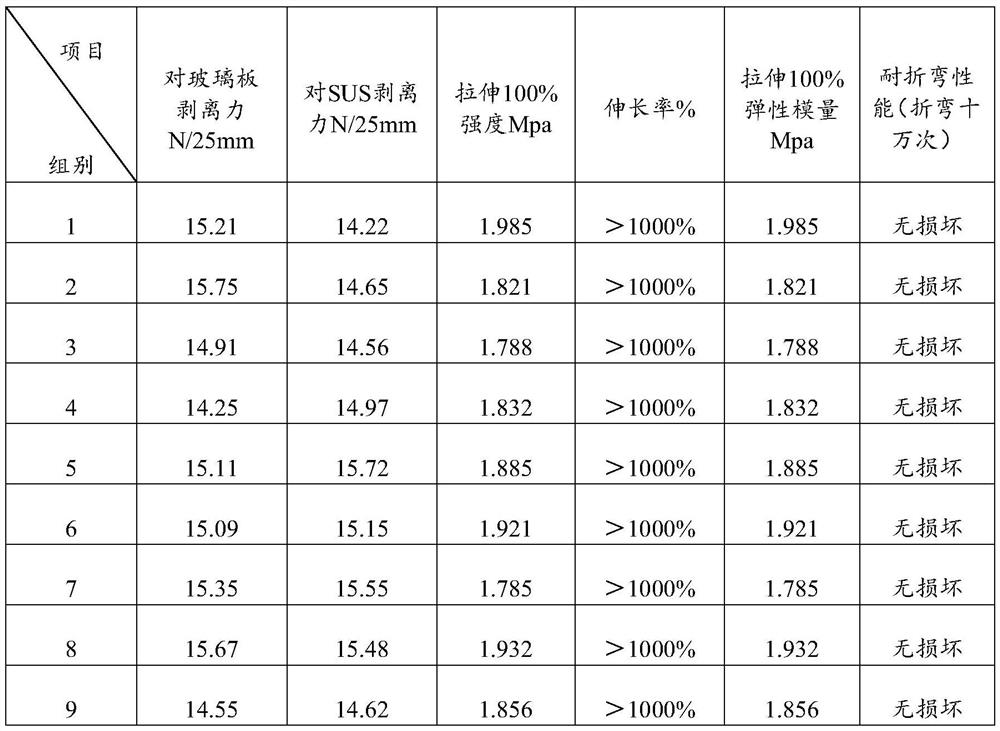

[0029] The thickness of the first release film and the second release film is 50-75 μm, the thickness of the TPU base film layer is 15-20 μm, and the thickness of the first adhesive layer and the second adhesive layer is 15-25 μm , when the flexible double-sided adhesive tape is stretched by 100%, the elastic modulus E<2Mpa.

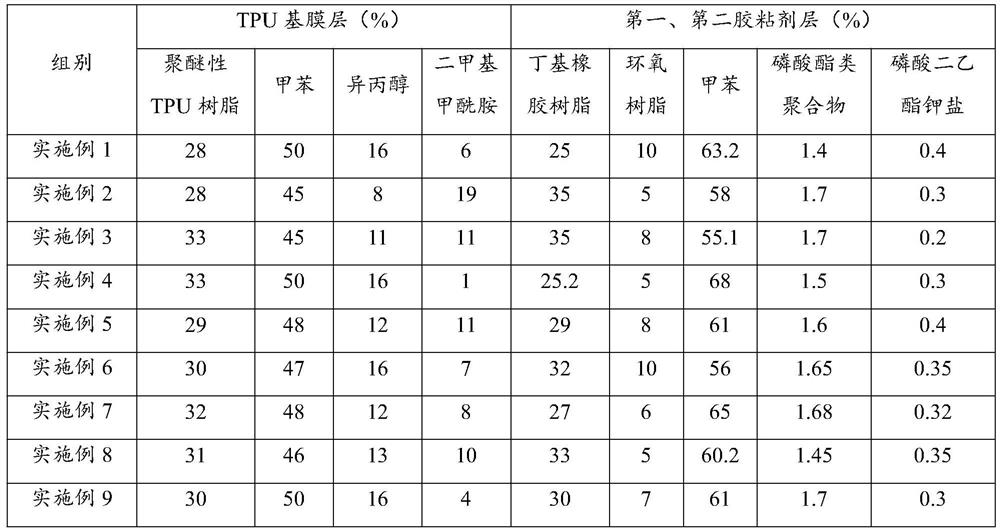

[0030] The glue formula of the TPU base film layer includes 28-33% polyether TPU resin, 45-50% toluene, 8-16% isopropanol, 1-19% dimethylformamide, and the above percentages are mass percentages; The glue formula of the first adhesive lay...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap