Spherical steel support trolley for retractable roof

A technology of steel support trolley and steel support, which is applied to roofs, building components, buildings, etc., and can solve problems such as huge equipment, increased risks, and complex equipment structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the technical means of the present invention and the technical effects that can be achieved more clearly and more perfectly disclosed, the following embodiments are provided hereby, and the following detailed descriptions are made in conjunction with the accompanying drawings:

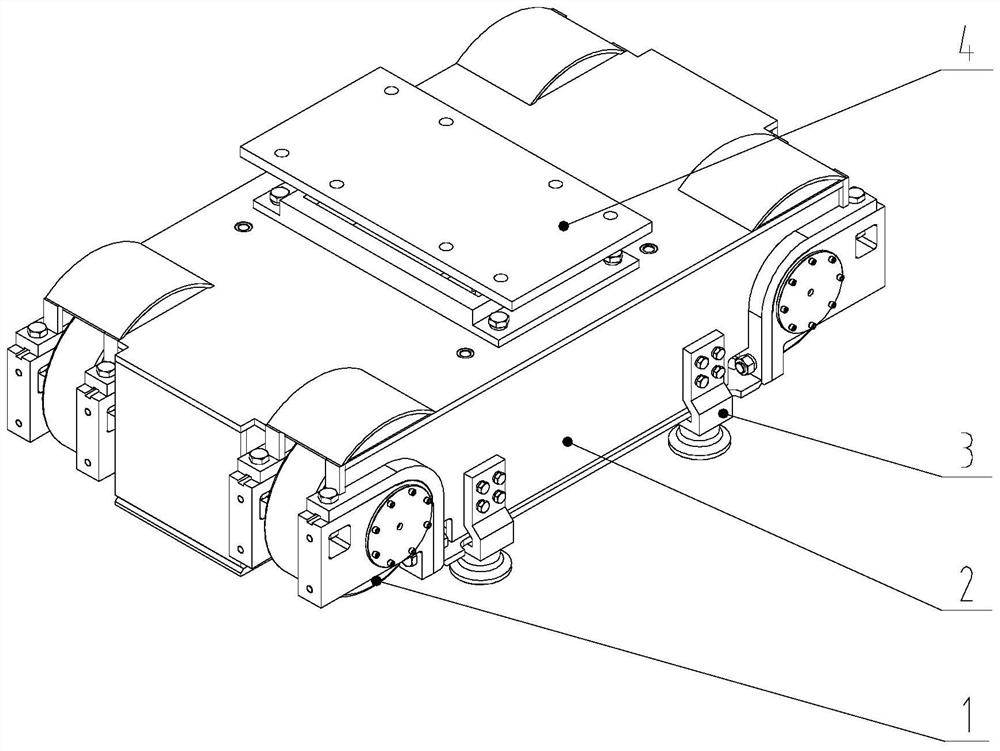

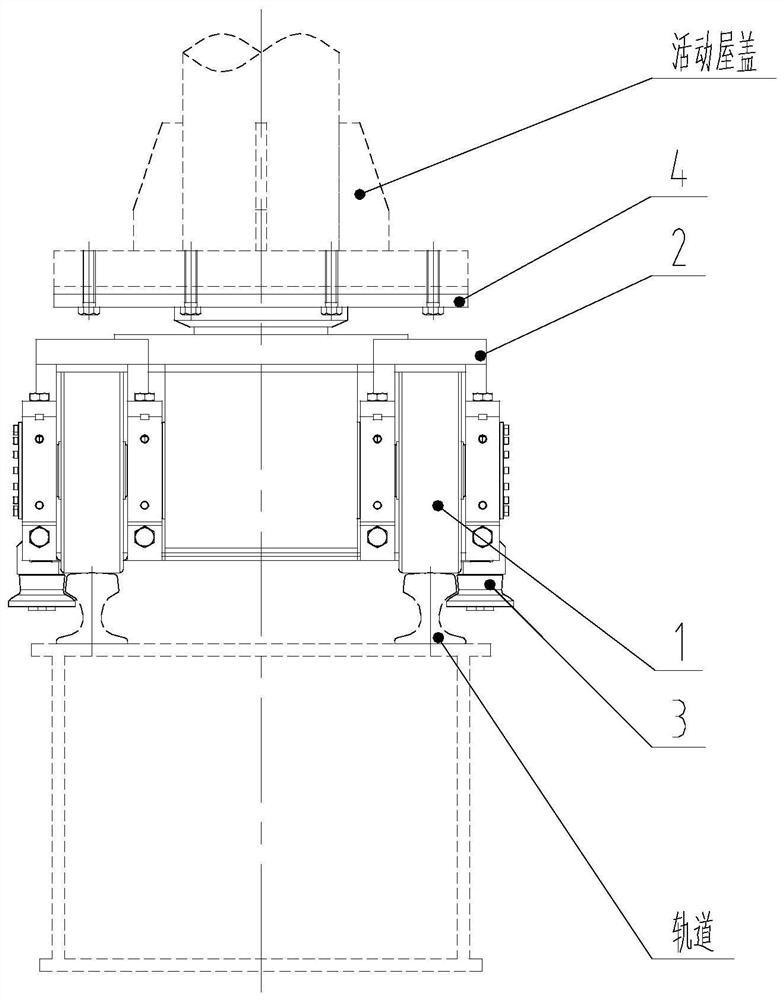

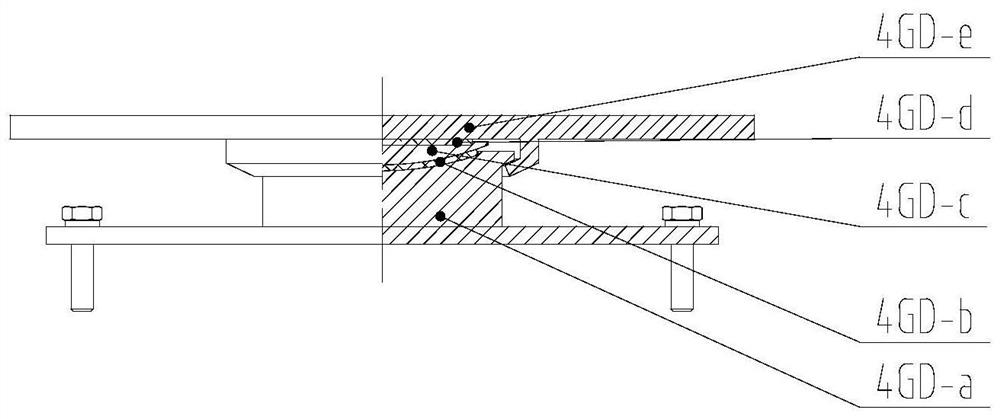

[0026] Such as figure 1 It is an axonometric drawing of the spherical steel support trolley in this embodiment, and the spherical steel support trolley includes a wheel set 1 , a vehicle frame 2 , a guiding anti-hook device 3 and a spherical steel support 4 . Such as figure 2 It is the structure and installation diagram of the trolley with spherical steel support in this embodiment. The trolley has 4 sets of standard crane wheel sets 1. During installation, the 4 wheel sets are placed on parallel double rails; forming a relatively stable four-wheel double-rail form. The parallelism of the double rails requires high parallelism and is generally installed on integrated box beams...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com