Aerial rail traffic bridge spherical steel support

A technology of aerial track and spherical steel, which is applied in the field of rail transit, can solve problems such as difficult construction, over-limit variation of expansion joints, and inability to install, so as to ensure smoothness and safety, reduce construction accuracy, and reduce construction difficulty Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

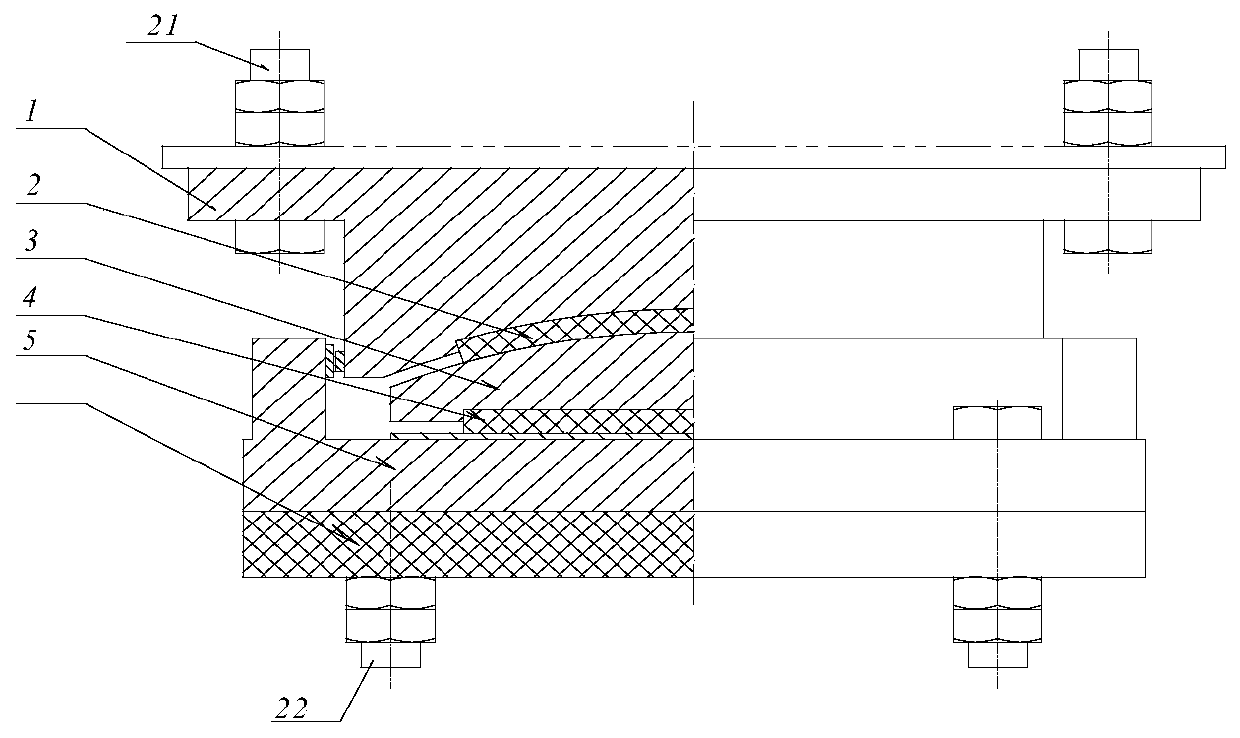

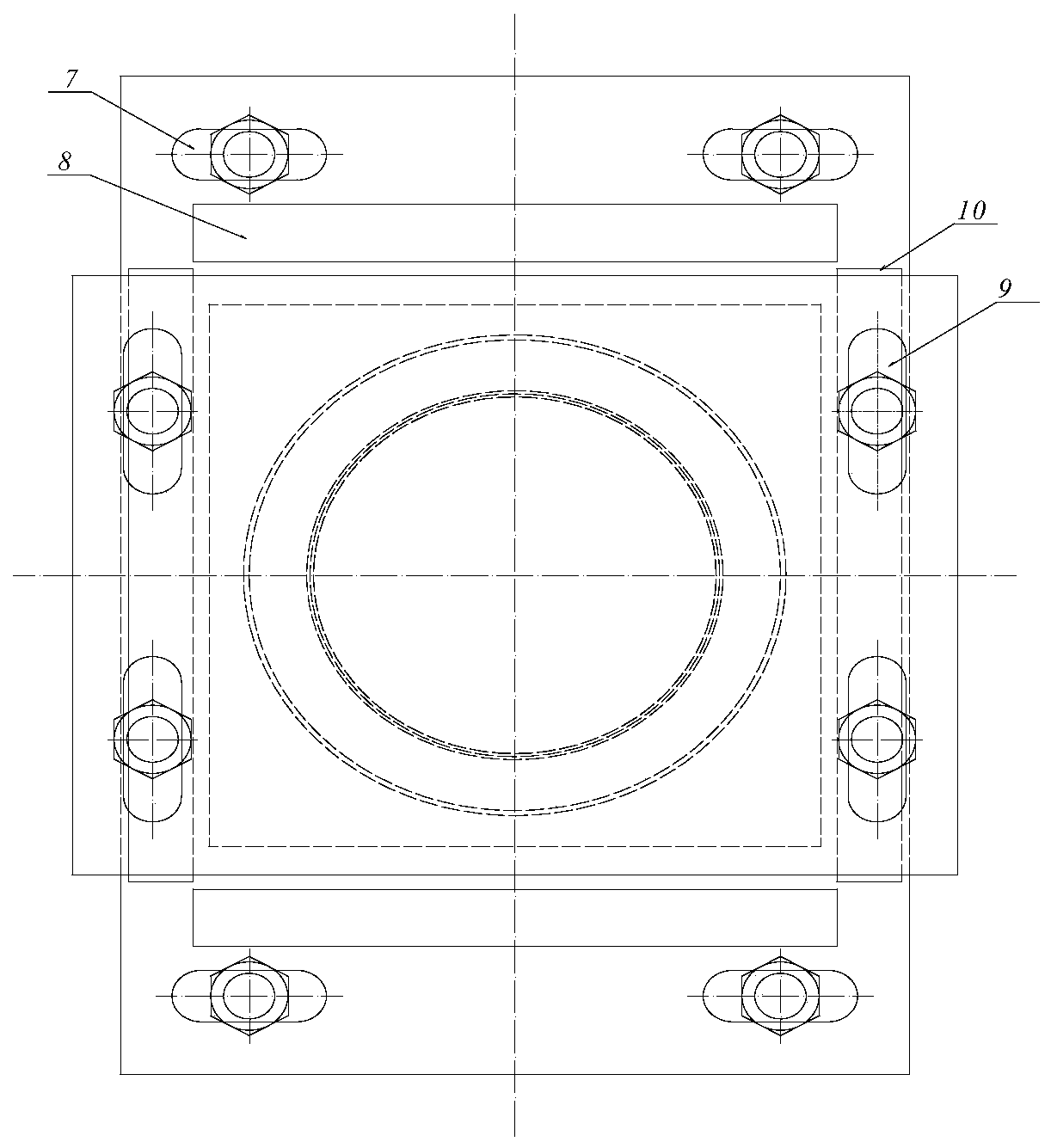

[0016] refer to figure 1 with figure 2 , the spherical steel bearing of the aerial rail transit bridge of the present invention is arranged between the beam body and the pier body, including an upper bearing plate, a lower bearing plate and a spherical crown lining plate between the two, and the lower part of the upper bearing plate The bottom surface of the structure forms a rotating friction pair with the upper spherical surface of the spherical crown liner, and the bottom surface of the spherical crown liner forms a sliding friction pair with the top surface of the lower support plate. Longitudinal adjustment holes are arranged longitudinally at intervals on both lateral sides of the upper support plate, and upper connecting bolts 21 connecting the upper support plate 1 and the beam body are arranged at 9 places of each longitudinal adjustment hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com