Grouting connection node for deepwater floating type platform steel structures

A floating platform, grouting connection technology, applied in the direction of floating buildings, building structures, buildings, etc., can solve the problems of increasing structural thickness, harsh environmental conditions, difficult grouting connection technology and methods, etc., to improve the bearing capacity, improve Bond strength, effect of increasing global stiffness and local stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

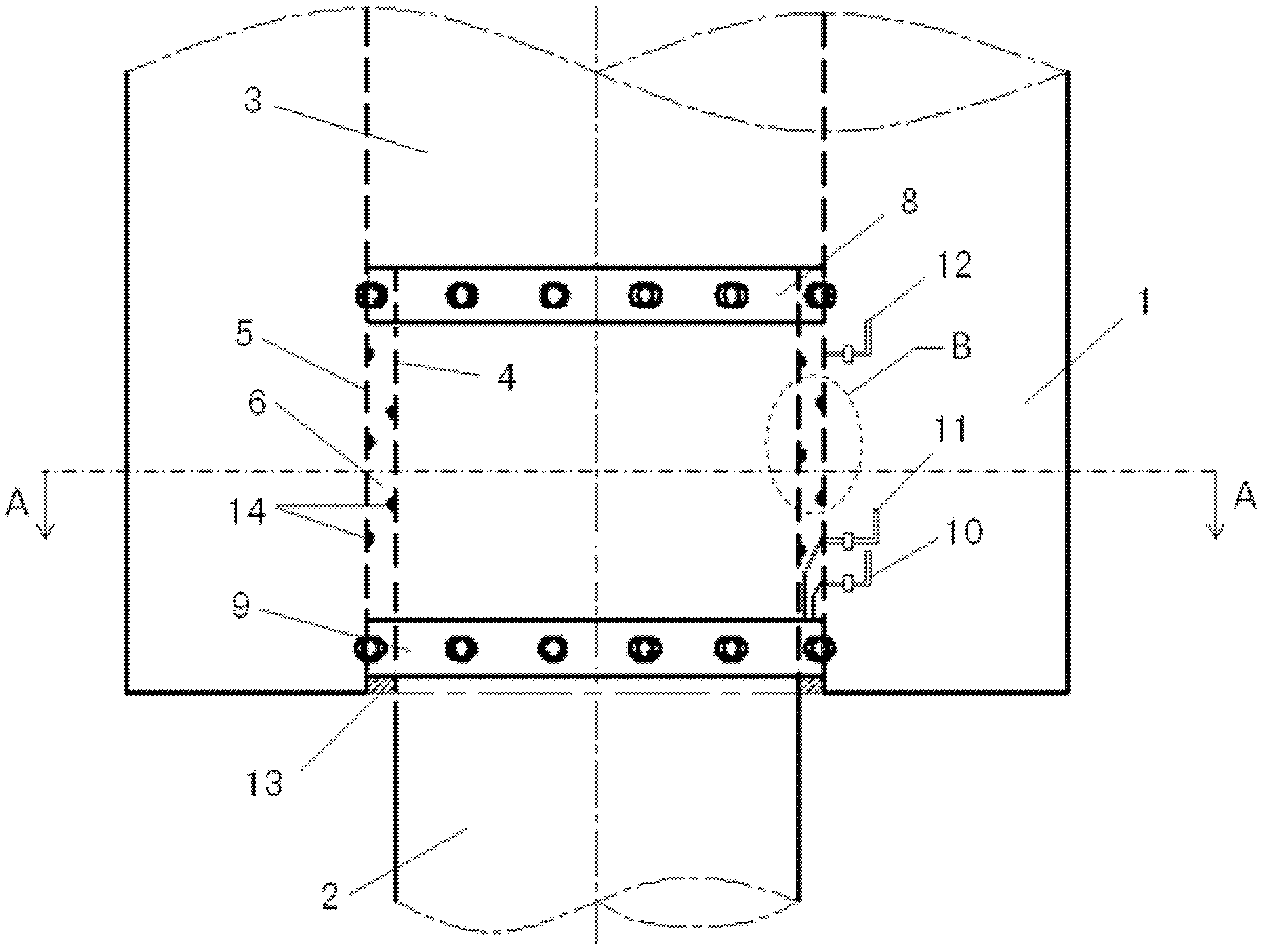

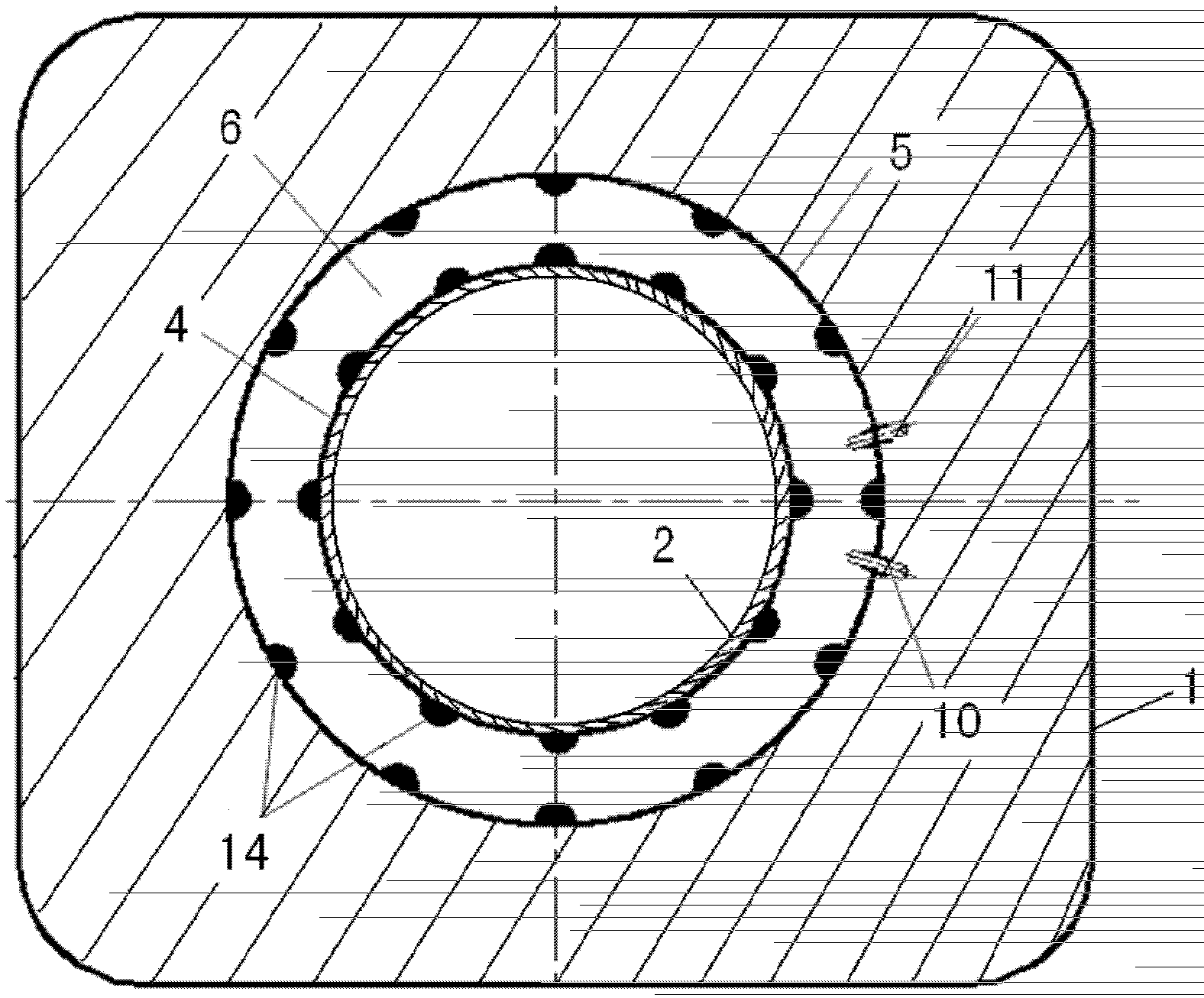

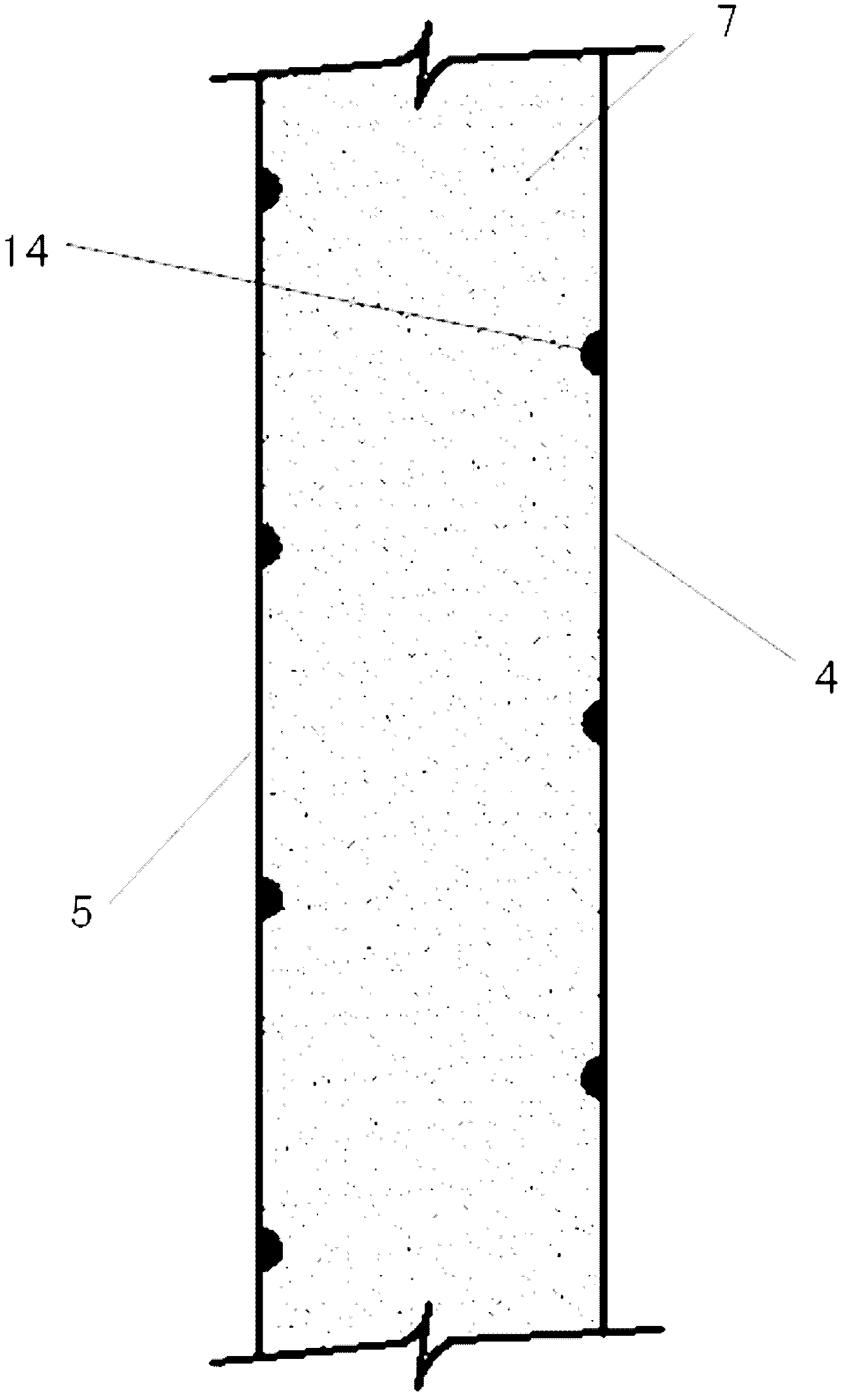

[0019] Such as Figure 1 ~ Figure 3 As shown, the present invention includes the outer column 1 and the inner column 2 in the existing deep-water floating platform, and a central channel 3 is arranged in the outer column 1 along the axis direction. A section of the top of the inner column 2 extends into the central channel 3 of the outer column 1, and an annular space 6 is formed between the outer wall surface 4 at the top of the inner column 2 and the inner wall surface 5 of the central channel 3, and the grouting material 7 is arranged in the annular space 6. At the top of the inner column 2, the top of the inner column 2 is fixedly connected to the outer column 1 through the upper fixing device 8; at the bottom of the outer column 1, the bottom of the outer column 1 is fixedly connected to the inner column 2 through the lower fixing device 9, which...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com