A dust filter for the front vacuum pump of a laminator

A dust filter and vacuum pump technology, applied in machine/engine, pump, pump components, etc., can solve the problems of high cost, vacuum pump oil pollution, and high vacuum pump replacement frequency, so as to increase the probability of contact mixing and increase the contact area. , to ensure the effect of fluency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

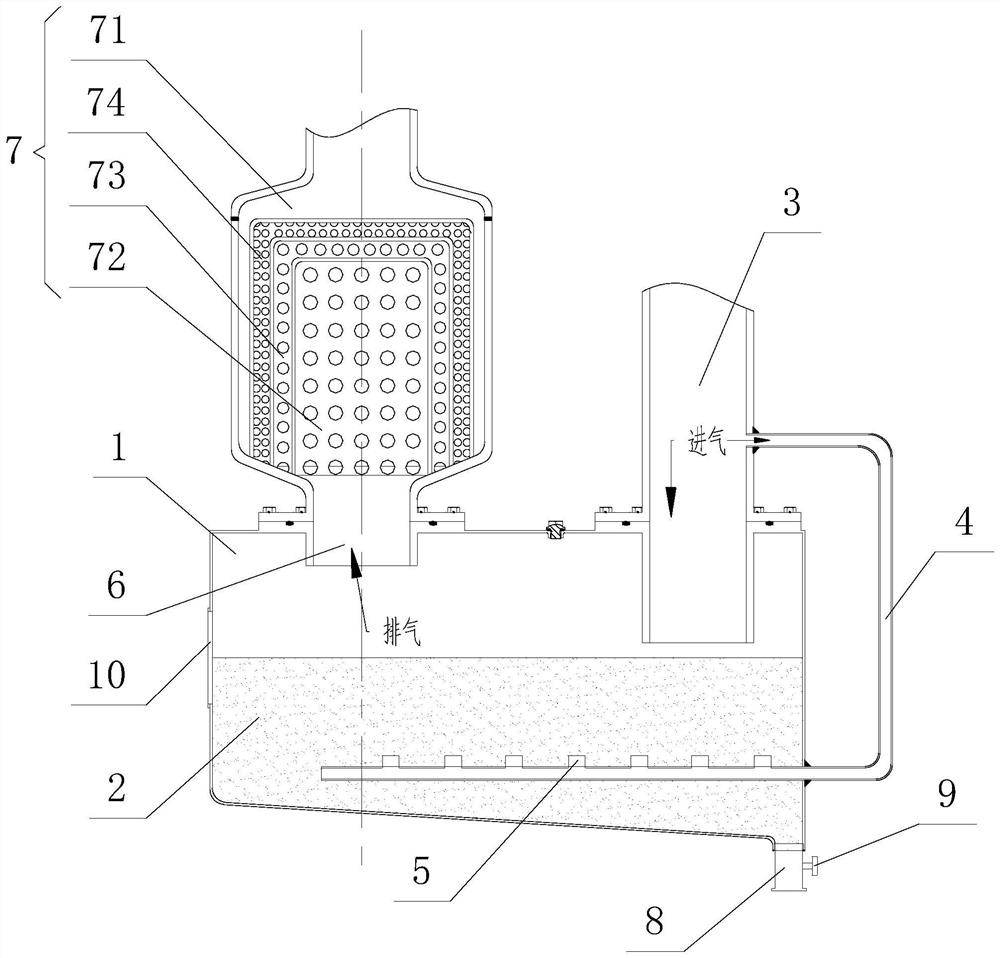

[0025] like figure 1 As shown, the dust filter for the front-stage vacuum pump of the laminator provided in this embodiment includes a sealed filter box 1, and the filter box 1 is equipped with vacuum oil 2, and the liquid level of the vacuum oil 2 exceeds the middle of the filter box 1. An air inlet is opened on one side of the top of the filter box 1, and an air outlet is opened on the other side. A fixing flange is installed on the outer wall of the filter box 1 at the air inlet, and a connecting flange is sleeved on the air inlet pipe 3. The connecting flange After being fixedly connected with the fixing flange, the air inlet pipe 3 is fixed at the air inlet, and a sealing ring is installed at the connection between the filter box 1 and the air inlet pipe 3, so as to ensure the sealing state of the filter box 1;

[0026] After the intake pipe 3 is fixed at the intake port, one end of the intake pipe 3 is located in the filter box 1, and the distance between the end of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com