Range hood

A technology for range hoods and hoods, which is applied to the removal of oil fume, household stoves/stoves, heating methods, etc., can solve problems such as uneven airflow and inability to suck up oil fume, so as to widen smoking channels, reduce air intake resistance, reduce The effect of changing the direction of the airflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

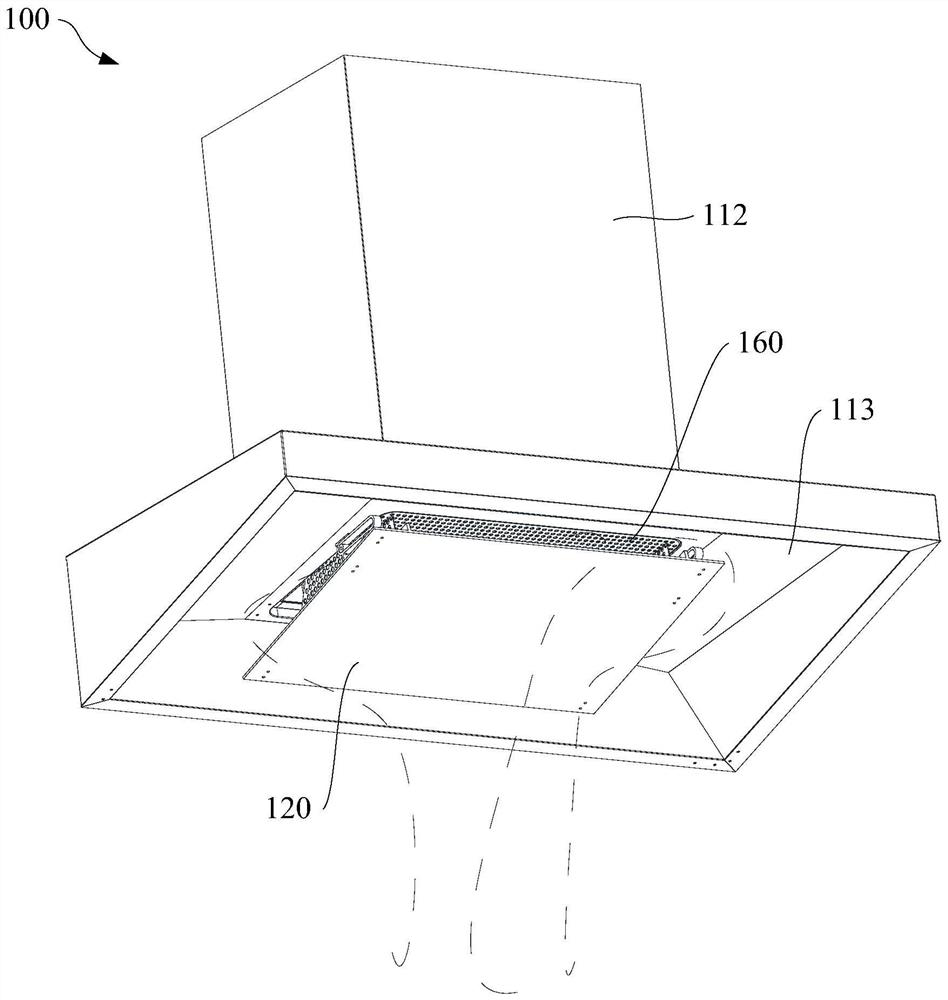

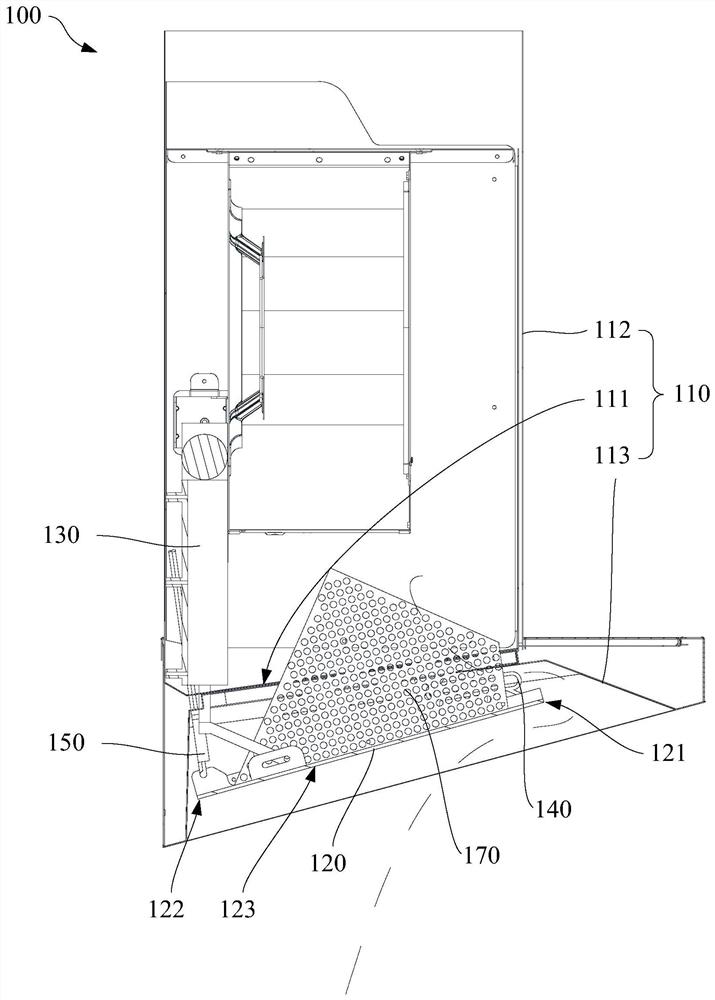

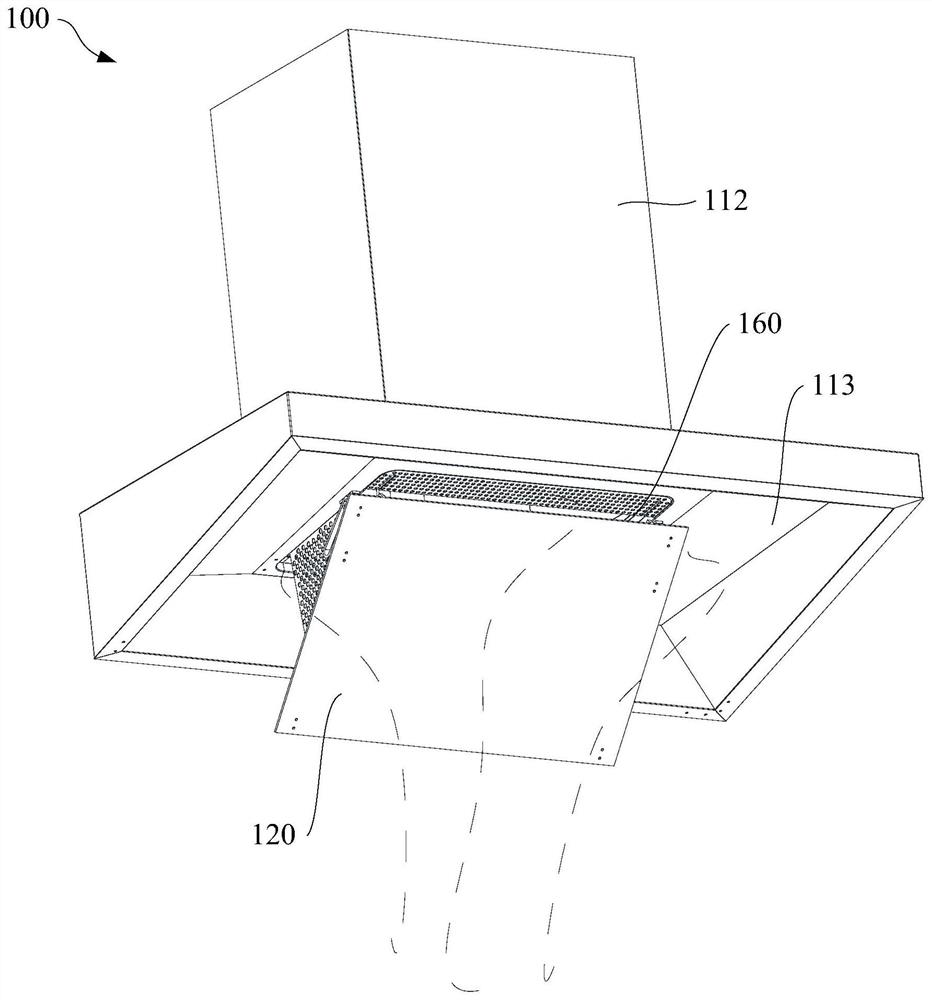

[0046] Such as Figure 1 to Figure 4 As shown (the dotted line in the figure shows the airflow direction), Embodiment 1 of the present invention provides a range hood 100 , and the range hood 100 includes a range hood body 110 , a condensation plate 120 , a drive assembly 130 and a limit assembly 140 . Wherein, the hood body 110 includes an air inlet 111; the condensing plate 120 is located at the air inlet 111, and the condensing plate 120 includes a first end 121 and a second end 122 facing away from each other; the driving assembly 130 is connected with the hood body 110, and the driving assembly 130 can drive the second end 122 of the condensation plate 120 to rotate around the first end 121 of the condensation plate 120; the limit assembly 140 connects the hood body 110 and the first end 121 of the condensation plate 120, and the limit assembly 140 can When the second end 122 of the plate 120 moves away from the air inlet 111 , the first end 121 of the condensation plate ...

Embodiment 2

[0050] On the basis of Embodiment 1, Embodiment 2 provides a range hood 100, wherein the drive assembly 130 is connected to the condensation plate 120, and the reliable connection between the drive assembly 130 and the condensation plate 120 can be realized, so that the drive assembly 130 not only The condensing plate 120 can be pushed to rotate away from the air inlet 111 , and the condensing plate 120 can also be pulled to rotate in a direction close to the air inlet 111 , so as to realize switching between different smoking states. In addition, the connection mode between the driving assembly 130 and the condensation plate 120 is specifically a rotational connection, which can realize the flexible rotation of the condensation plate 120 .

[0051] Specifically, such as Figure 6 and Figure 10 As shown, the driving assembly 130 includes a driving push rod 131 and a bending connecting arm 132. The driving pushing rod 131 is connected with the cigarette machine body 110, and ...

Embodiment 3

[0054] On the basis of any of the above embodiments, Embodiment 3 provides a range hood 100, wherein, as Figure 8 and Figure 9 As shown, the limiting assembly 140 includes a limiting groove 141 and a limiting protrusion 144 located therein, wherein one of the limiting groove 141 and the limiting protrusion 144 is connected to the smoke machine body 110, and the limiting groove 141 and the limiting protrusion 144 The other of the limiting protrusions 144 is connected to the first end 121 of the condensing plate 120, for example, the limiting groove 141 is connected to the hood body 110, and the limiting protrusion 144 is connected to the first end 121 of the condensing plate 120. connect. The limiting protrusion 144 extends along the depth direction of the limiting groove 141 , the limiting protrusion 144 can rotate in the limiting groove 141 , and the limiting protrusion 144 can reciprocate along the length direction of the limiting groove 141 . By making the limiting prot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com