A gas distribution device and a gas water heater using the device

A gas water heater and distribution device technology, which is applied to gas fuel burners, gaseous fuel supply/distribution, burners, etc., can solve the problems of large volume, high cost, and low grade of solenoid valves, so as to improve work reliability and facilitate The effect of processing and production, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

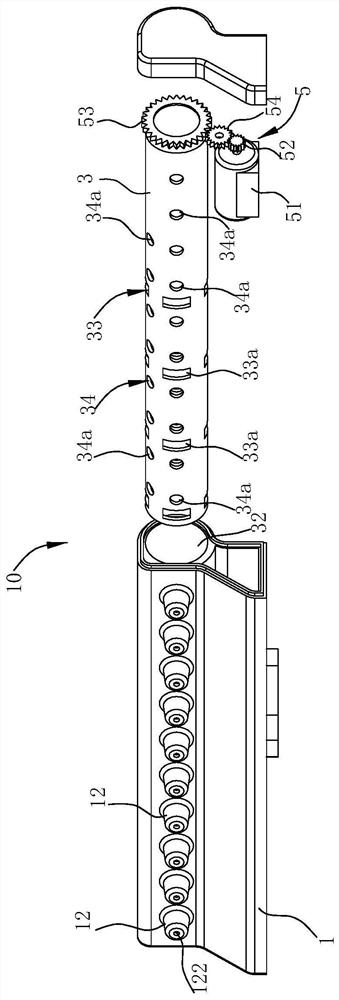

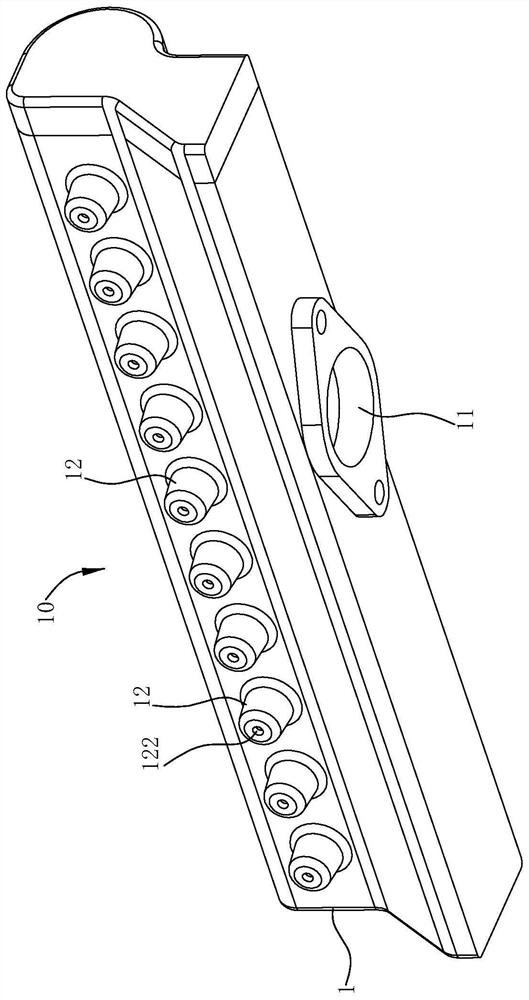

Method used

Image

Examples

Embodiment 2

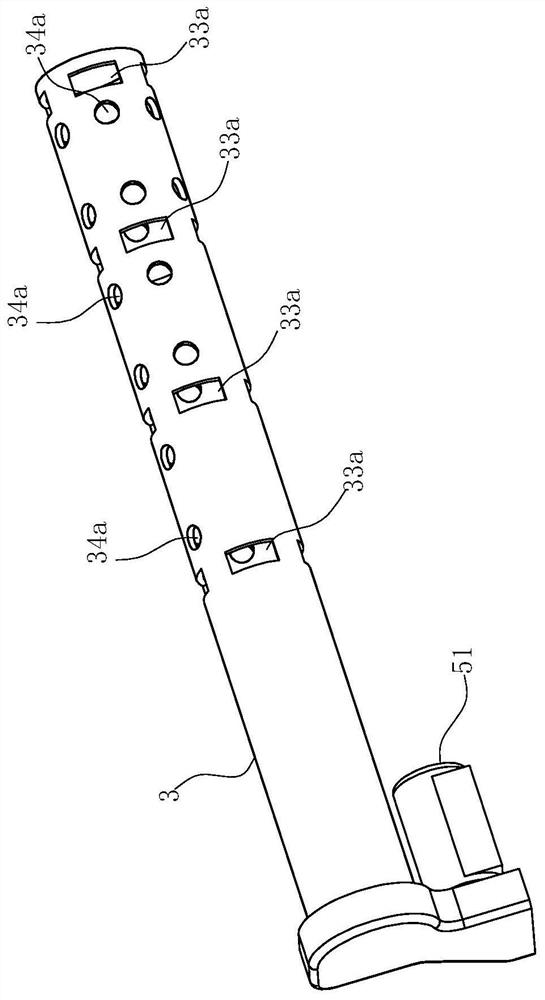

[0057] The difference between embodiment 2 and embodiment 1 lies in that the structure of the air outlet group is different.

[0058] like Figure 7 As shown, in order to prevent the air outlet group 34 from corresponding to the nozzle 12, when the position between the two air outlet holes 34a is aligned with the nozzle 12, the nozzle 12 is covered, so the air outlet holes 34a in at least one group of air outlet group 34 are connected That is, the air outlet group 34 is a strip-shaped hole belt, so that when the air outlet group 34 corresponds to the nozzle 12, the nozzle 12 always has gas flowing through it.

[0059] It can be seen from the above-mentioned multiple embodiments that the arrangement of the air outlet group 34 and the air outlet 34a can be defined, which is highly adjustable for different specific water heater models, has strong adaptability, is convenient for design changes, and can adjust the gas flow more flexibly and conveniently. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com